Rail brake device of gantry crane

A gantry crane and crane technology, applied in the directions of travel mechanism, transportation and packaging, load hanging components, etc., can solve the problems of easy sliding and insufficient structural resistance, and achieve the effect of improving braking effect, flexible and convenient application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

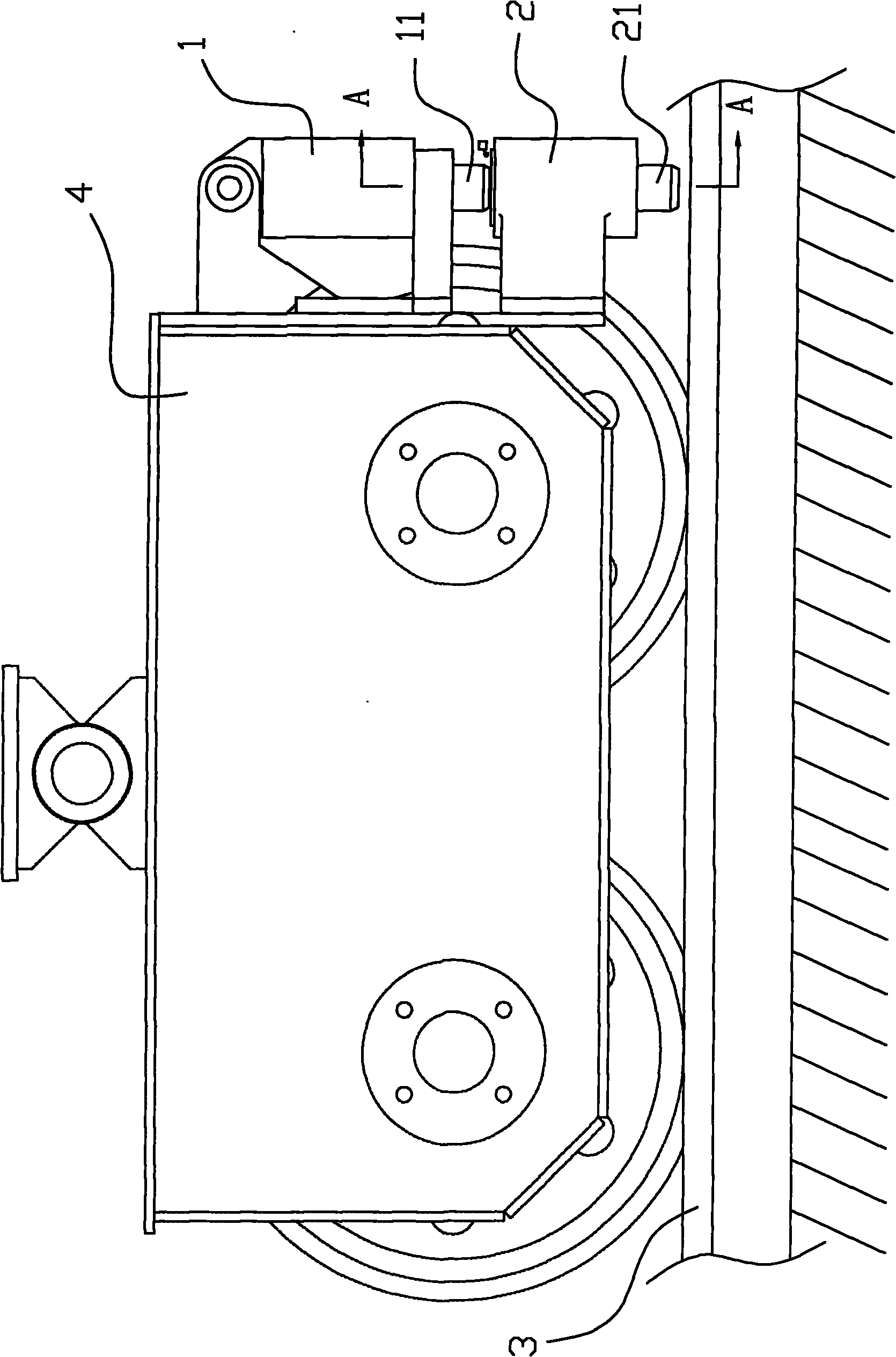

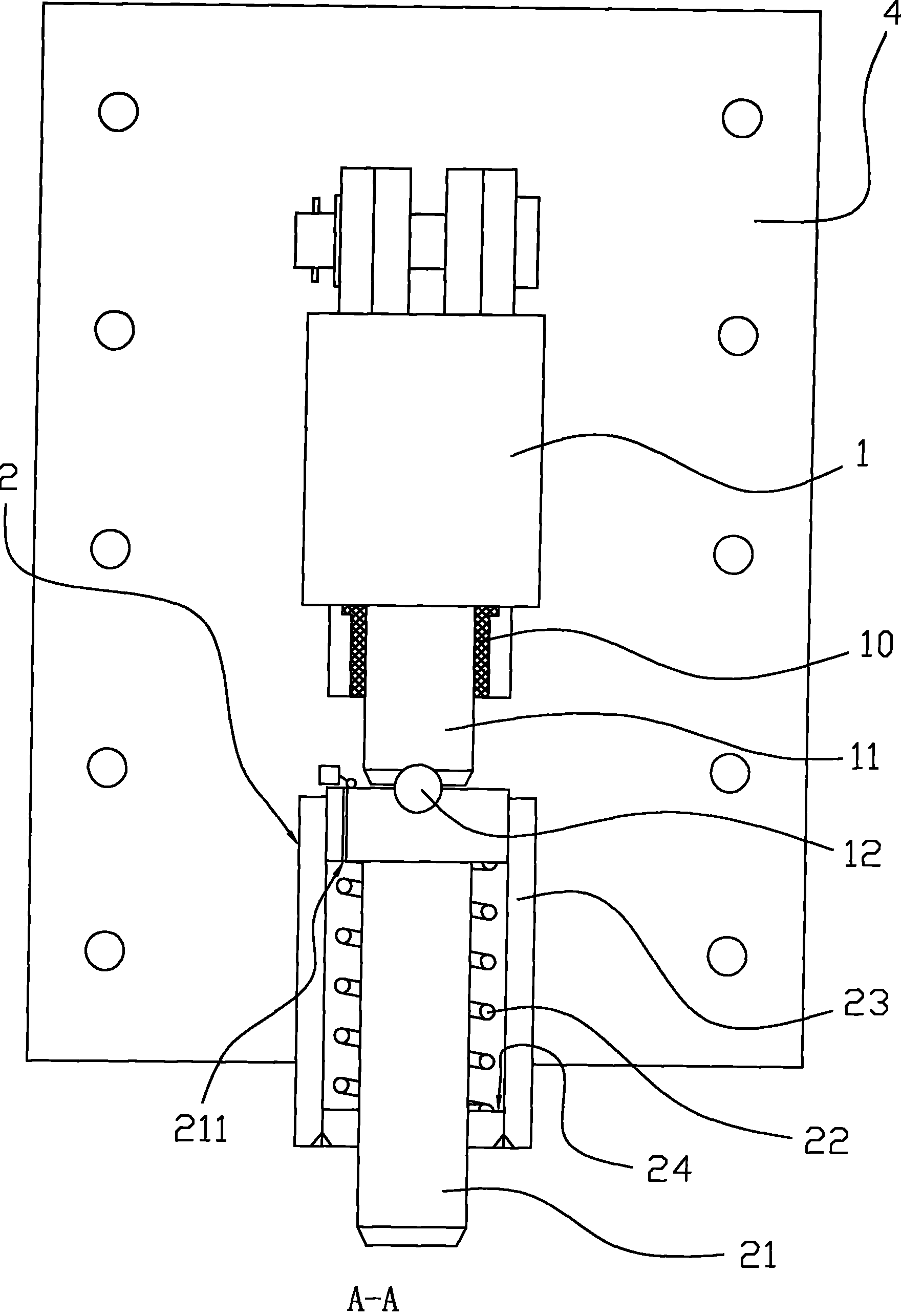

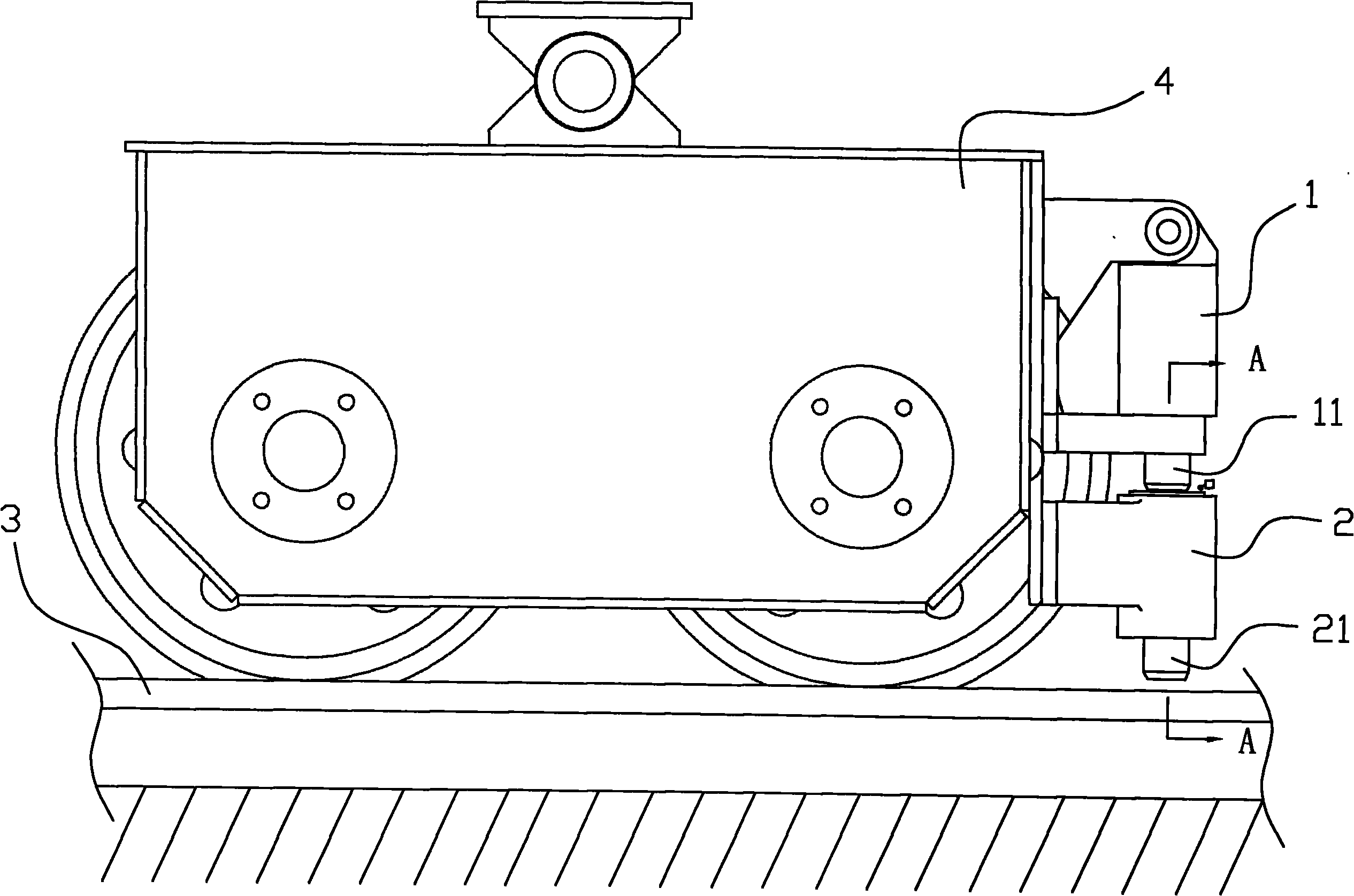

[0013] Such as figure 1 and figure 2 As shown, the top rail device of the gantry crane of this embodiment includes an oil cylinder 1 with a hydraulic lifting shaft 11 . Right below the hydraulic lifting shaft 11, a top rail device 2 is provided, and the top rail device 2 includes a casing 23 and a vertically arranged telescopic rod 21, and the above-mentioned telescopic rod 21 is arranged in the casing 23 so as to move up and down. The upper end of the telescopic rod 21 is in contact with the lower end of the hydraulic lifting shaft 11, and the lower end of the telescopic rod 21 can be in contact with the rail 3 when it extends downward, and the housing 23 and the oil cylinder 1 are fixed on the crane through the side. Drive 4 on. In order to reduce friction, the upper end surface of the telescopic rod 21 is preferably in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com