Sealing ring

A sealing ring, annular technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve problems such as affecting the sealing effect, and achieve the effect of good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

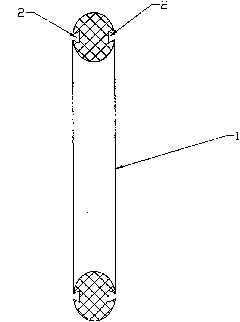

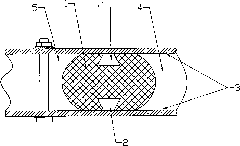

[0009] As shown in the figure, the sealing ring has an O-shaped annular base 1 with an O-shaped cross-section, and annular grooves 2 are respectively opened on the front and rear end faces of the annular base. The cross-sectional shape of the groove is narrow at the mouth and narrow at the bottom wide trapezoid.

[0010] During use, the front and rear end surfaces of the sealing ring are respectively pressed on the two sealing contact surfaces 3 that need to be sealed and connected, and the groove 2 forms a closed cavity. When the gas on the high-pressure side 4 leaks to the low-pressure side 5, it first enters the groove 2 Constitutes a closed cavity, with the increase of gas in the closed cavity, the pressure in it is also increasing, because it is a trapezoidal structure, the pressure generated by the pressure acts on the two sides of the trapezoid, and the vertical component force generated by it makes The base material of the sealing ring fits more closely with the contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com