Structure of supporting core assembly and bearing for a bldc

A brushed DC motor and bearing support technology is applied to electric components, casings/covers/supports, electrical components, etc., and can solve problems such as the expansion of the inner diameter of the core component 100, the reduction of the length direction of the core 110, and the increase of materials and assembly costs. , to achieve the effect of reducing material cost, improving support structure, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

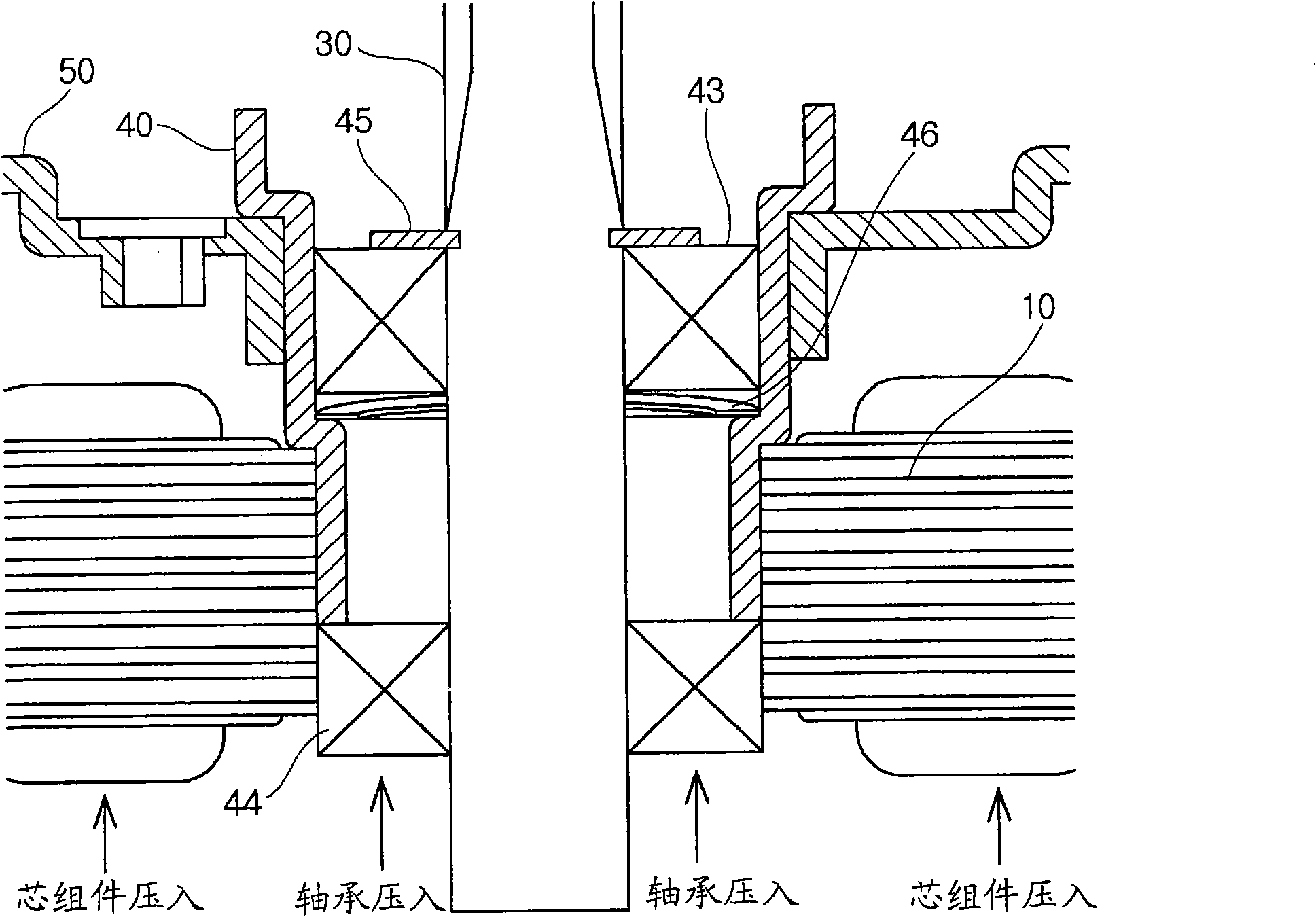

[0031] Hereinafter, the core assembly and the bearing support structure of the brushless DC motor of the present invention will be described in detail with reference to the drawings.

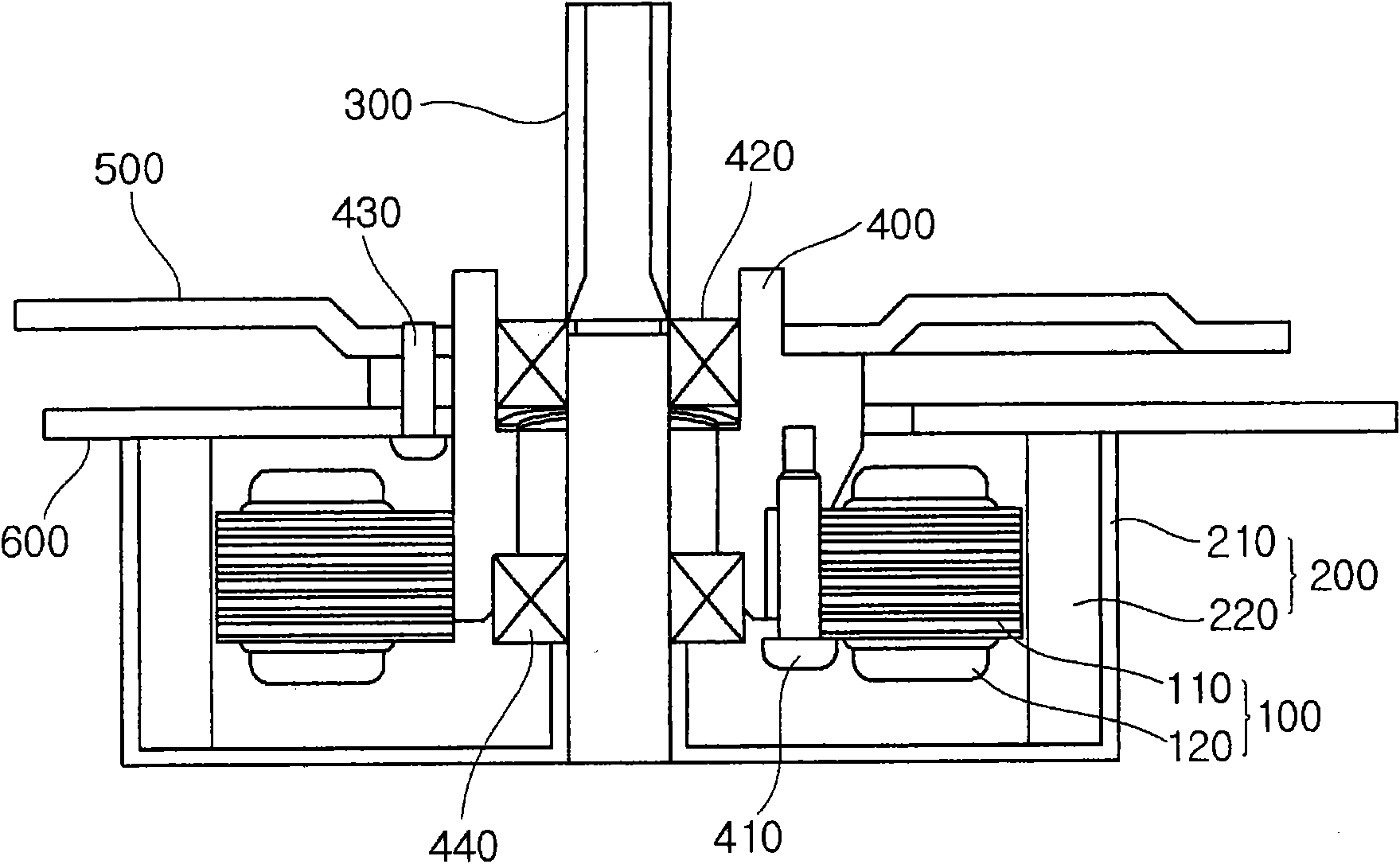

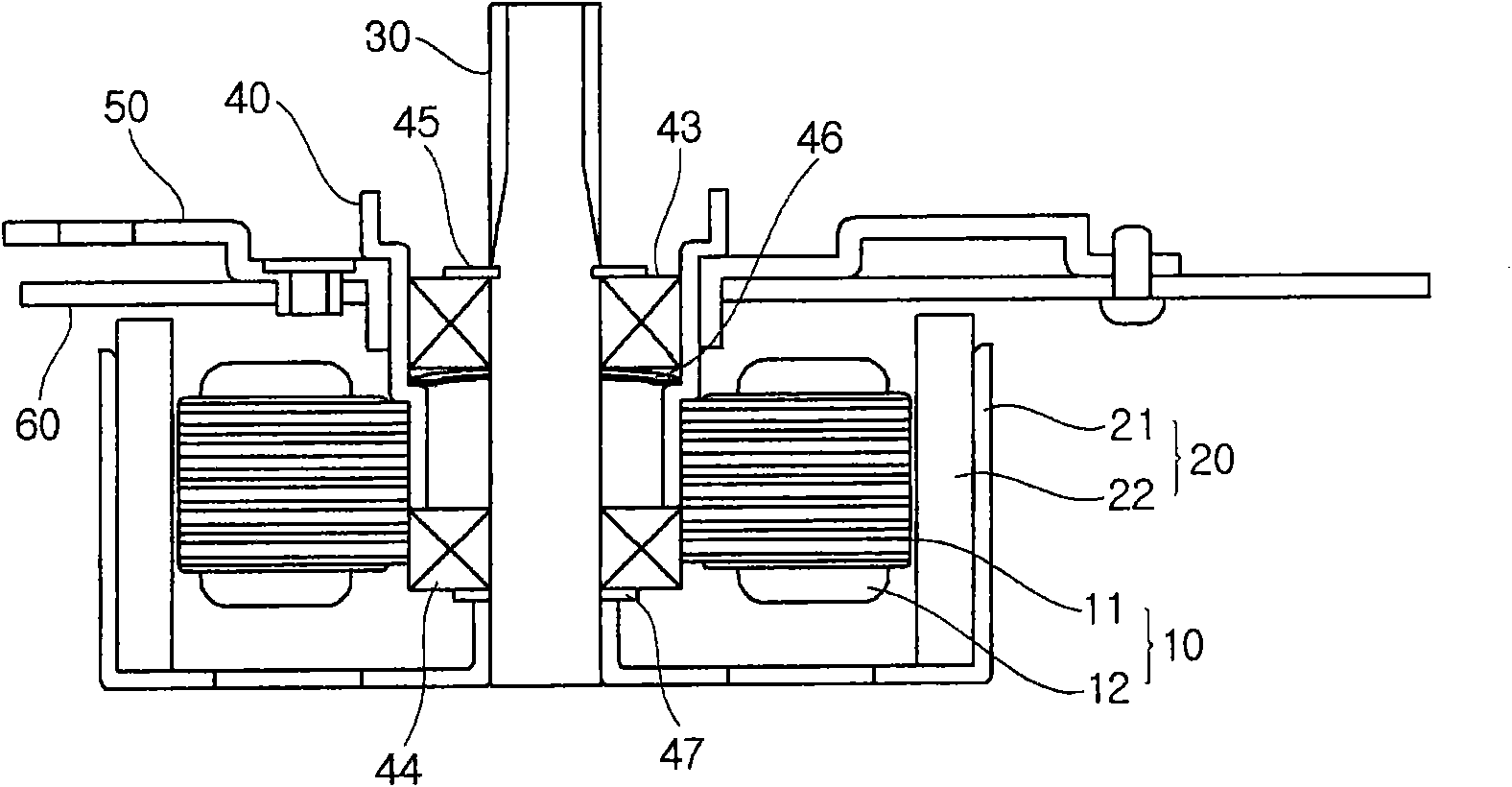

[0032] figure 2 is a sectional view showing the brushless DC motor of the present invention, image 3 yes figure 2 Detailed structural diagram of the core assembly and bearing support structure in .

[0033] Such as figure 2 As shown, the brushless DC motor of the present invention includes: a stator, which is composed of a core assembly 10 formed by winding a coil 12 on a core 11 radially having an inner diameter portion of a certain size inside; and a rotor 20, which It is composed of a ring magnet 22 and a rotor yoke 21. The magnet 22 is opposed to the core assembly 10 at a certain distance (gap portion) from the outer peripheral surface of the core assembly 10. The rotor yoke 21 attaches the magnet 22 to the On the inner peripheral surface, a rotating shaft 30 for rotating the rotor 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com