Hydraulic unit for slip-controlled braking systems

一种液压单元、制动系统的技术,应用在用于弹性流体的泵送装置的部件、制动器、泵元件等方向,能够解决耗费空间的定位、钻孔技术高成本和复杂性等问题,达到降低复杂性和成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

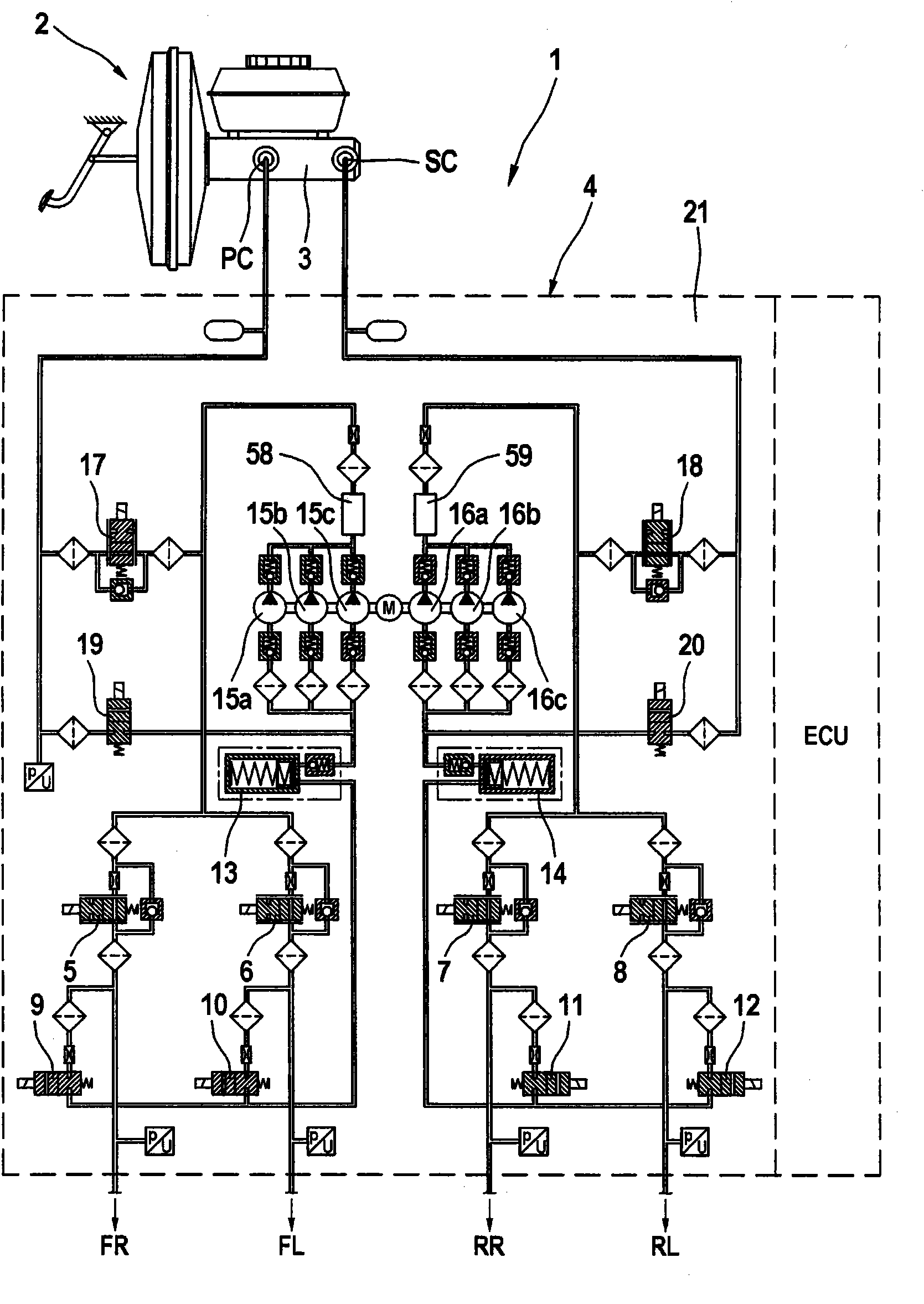

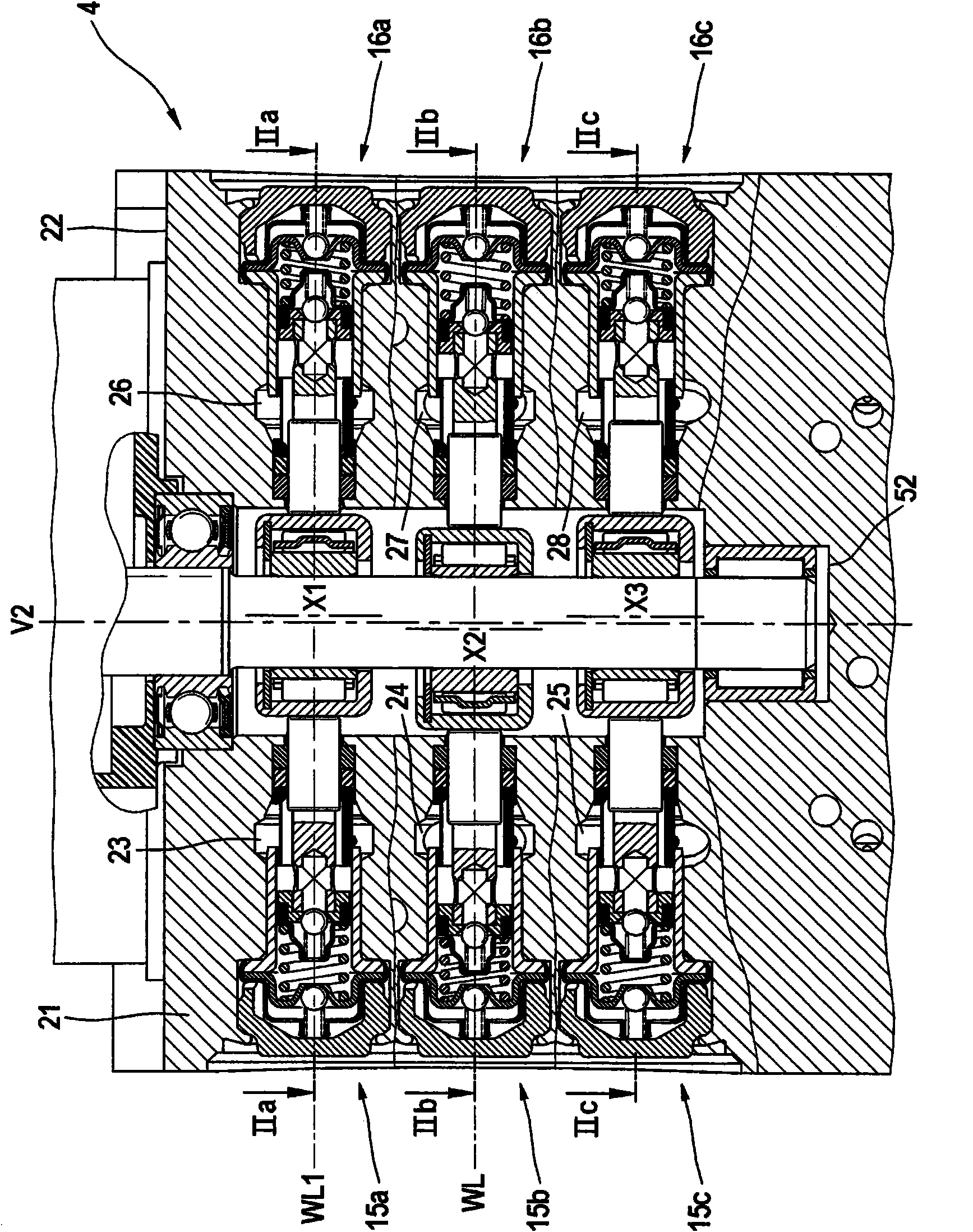

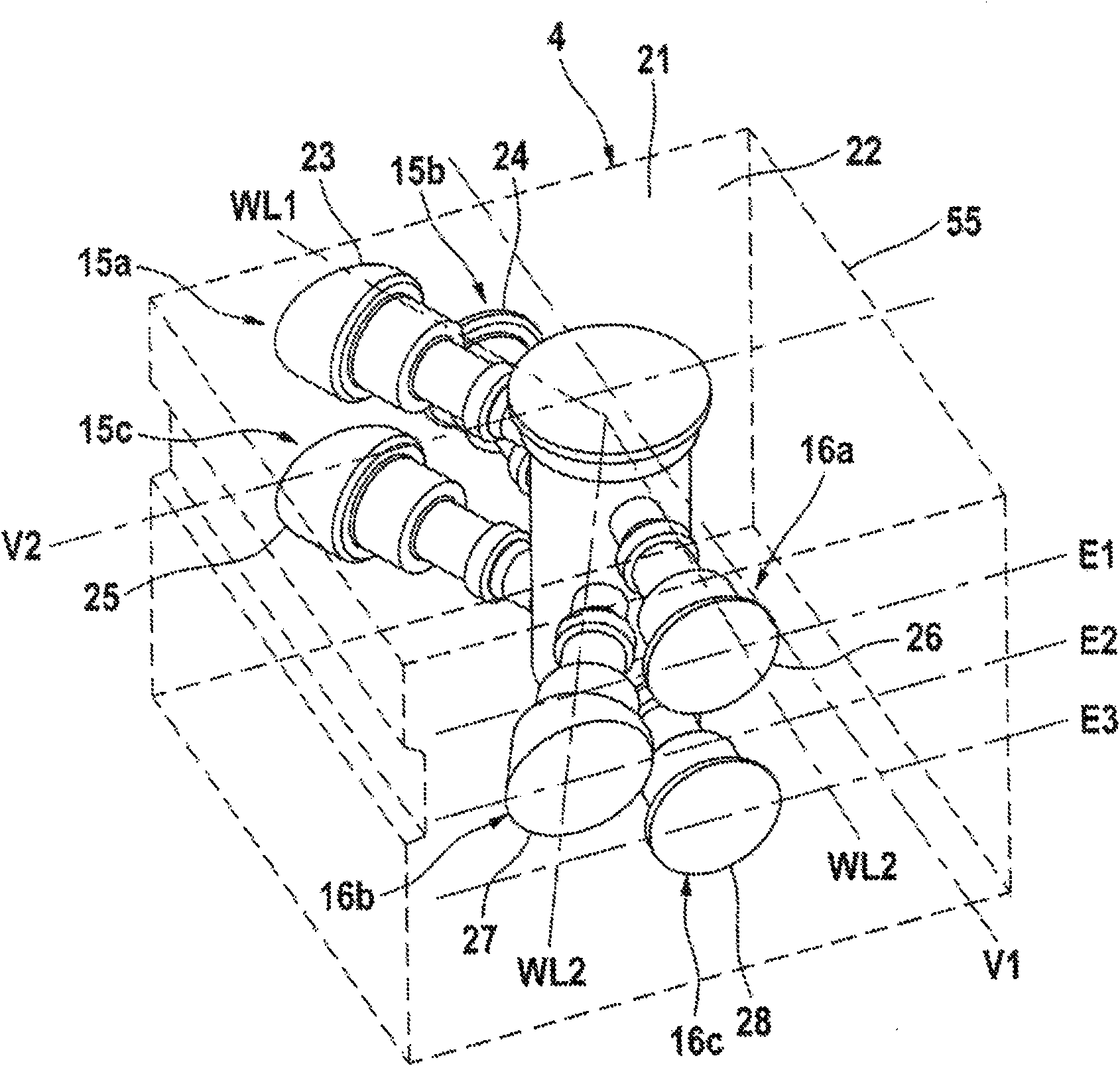

[0025] according to figure 1 , the electrohydraulic braking system 1 comprises an actuating unit 2 with a master cylinder 3 and two wheel brakes FR, FL, RR, RL each arranged in two different hydraulic circuits, the wheel brakes being clustered ground and independently connected to the primary pressure chamber PC or the secondary pressure chamber SC of the master cylinder 3 .

[0026] In the connection between the master cylinder 3 and the wheel brakes FR, FL, RR, RL there is another hydraulic unit 4 with an electronic control unit ECU that can realize braking or driving anti-slip control. For this purpose, the hydraulic unit 4 comprises, in the receiving body 21, inlet valves 5-8, which are open when there is no current, and outlet valves 9-12, which are closed when there is no current, which are connected in pairs to the wheel brakes FR, FL, RR. , upstream of RL.

[0027] By activating the outlet valves 9-12 which are closed when there is no current and discharging the hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com