Driving device

A technology of transmission device and transmission gear, applied in the direction of hoisting device, portable lifting device, belt/chain/gear, etc., can solve the problems of not easy to process splines, difficult to process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

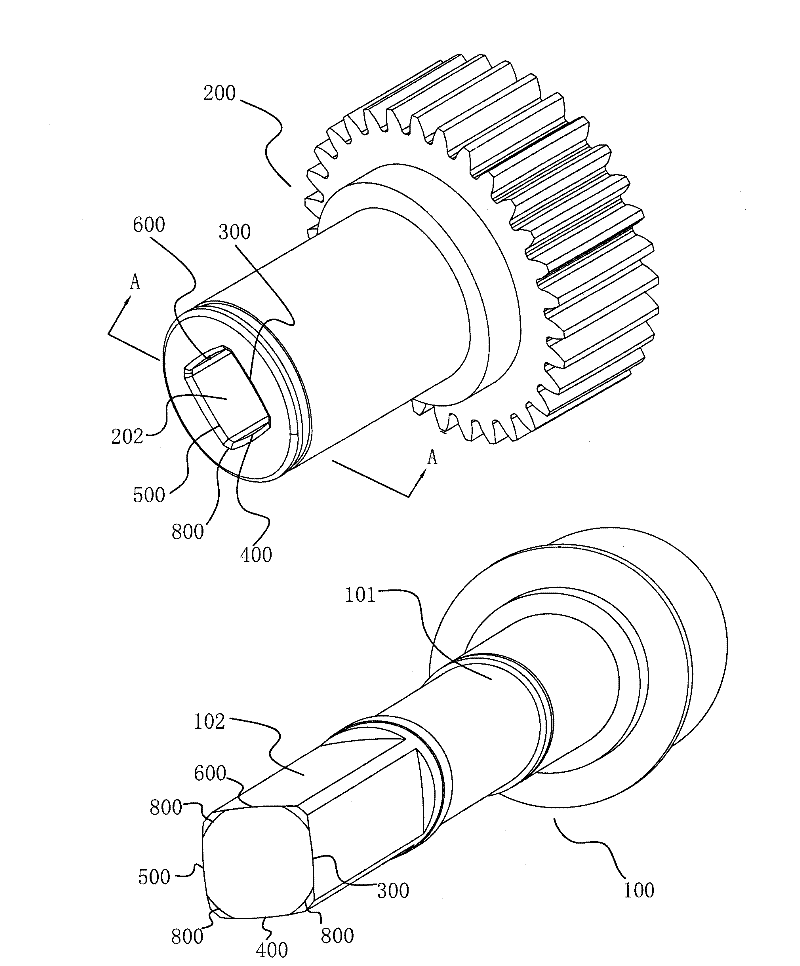

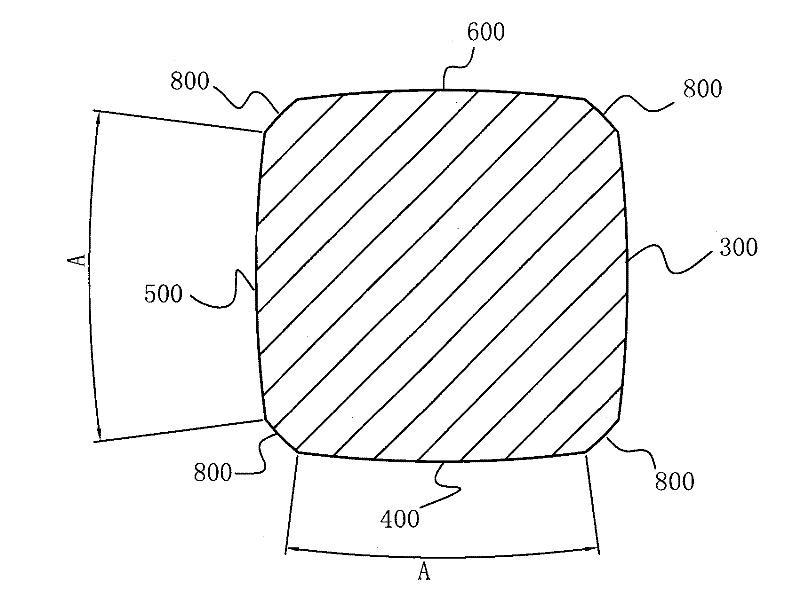

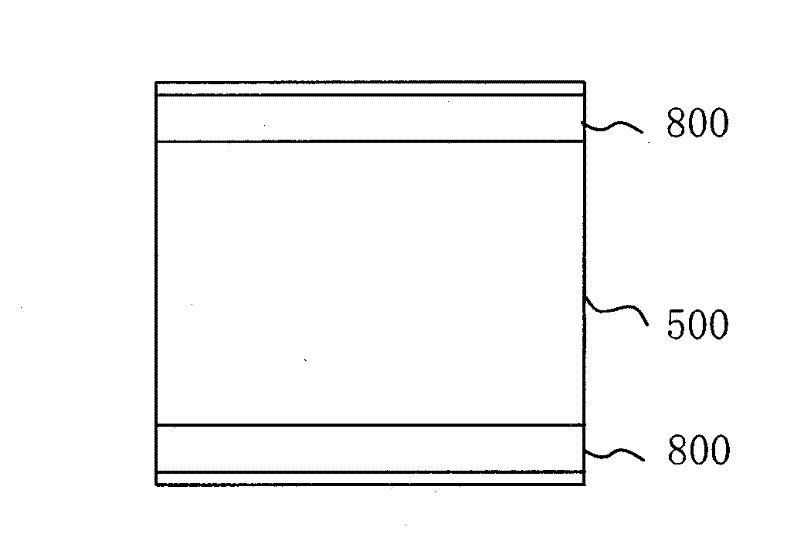

[0024] A transmission device such as figure 1 As shown, the drill rod 100 and the transmission gear 200 are included. The drill rod 100 cooperates with the transmission gear 200 to transmit the power of the drill rod 100. The drill rod 100 includes a drill rod main body 101 and a connecting end 102, and the connecting end 102 is used to cooperate with the transmission gear 200. The cross section of the connecting end 102 of the drill rod 100 perpendicular to the axis of the drill rod 100 is a circular arc quadrilateral, such as figure 2 , image 3 Shown. Such as Figure 4 , Figure 5 As shown, the transmission gear 200 is provided with a special-shaped hole 202 that is matched with the connecting end 102 of the drill rod 100, and the cross-section of the special-shaped hole 202 perpendicular to the axis of the transmission gear 200 is also a circular arc quadrilateral. The connecting end 102 of the drill rod 100 is assembled in the special-shaped hole 202 of the transmission...

Embodiment 2

[0031] A transmission device whose structure is the same as that of the first embodiment. The difference is that the radius of the four-segment arcs 300, 400, 500 and 600 of the arc quadrilateral is set to 24mm to meet the requirements when the shaft journal is only 15mm or 10mm occasion. Practice has proved that the transmission device can effectively transmit the power of the drill rod 100 when the journal is only 15mm and 10mm, and can also effectively center the transmission gear 200 and the drill rod 100 and ensure that the drill rod 100 is in the transmission gear 200. For axial sliding. The transmission device has low noise and convenient processing.

[0032] It should be noted that the radius of the four arcs 300, 400, 500, and 600 of the arc quadrilateral is not limited to 24 mm, and the radius can be flexibly set according to the size of the journal in the specific use environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com