A double meshing area arc tooth cylindrical gear mechanism and its processing method

A technology of cylindrical gear and arc tooth, which is applied in the field of double meshing area arc tooth cylindrical gear mechanism and its processing, can solve the problems of small load capacity, no corresponding patent and academic literature, etc., and achieve the elimination of axial load and symmetrical Easy to guarantee, good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

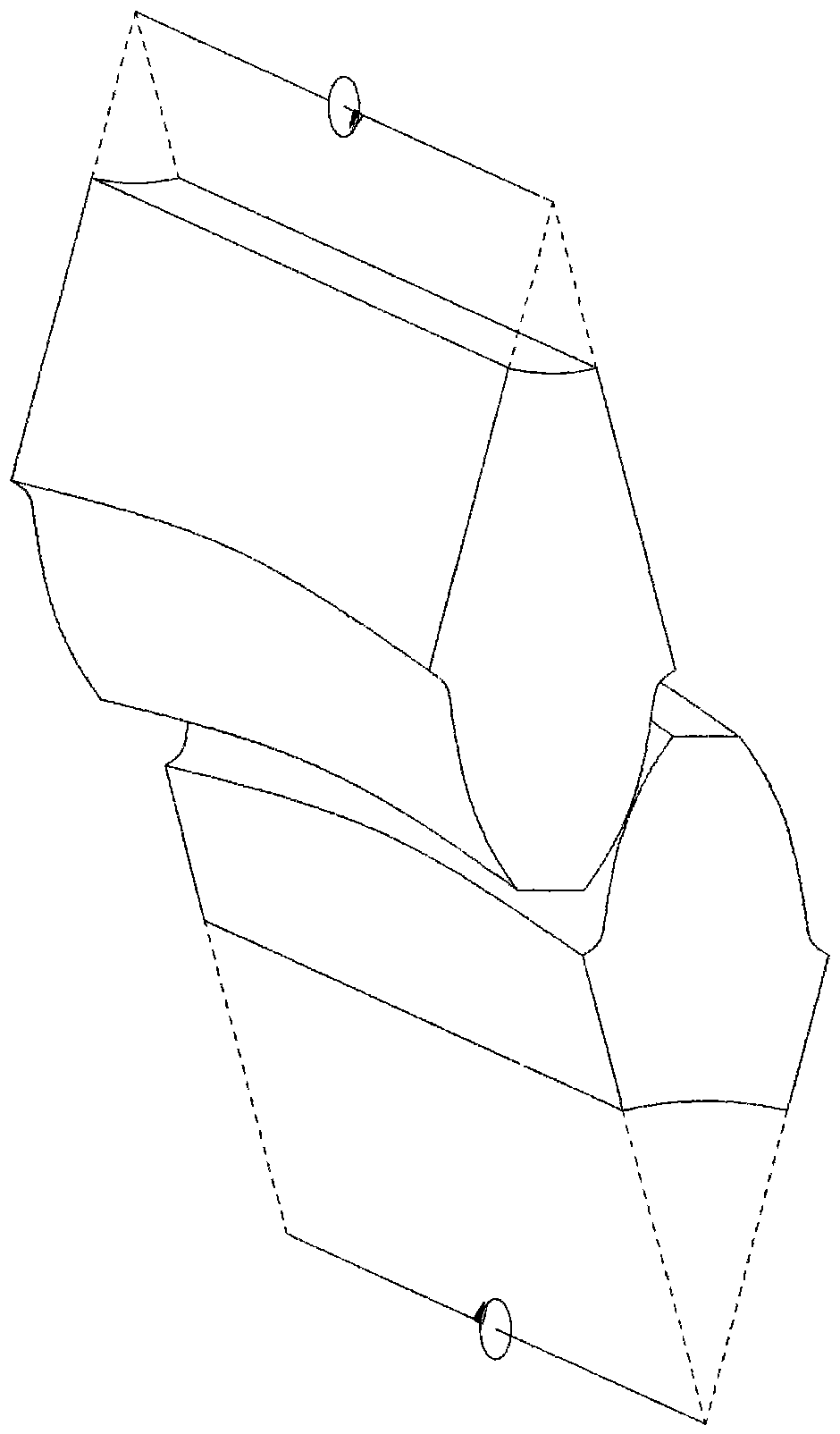

[0033] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

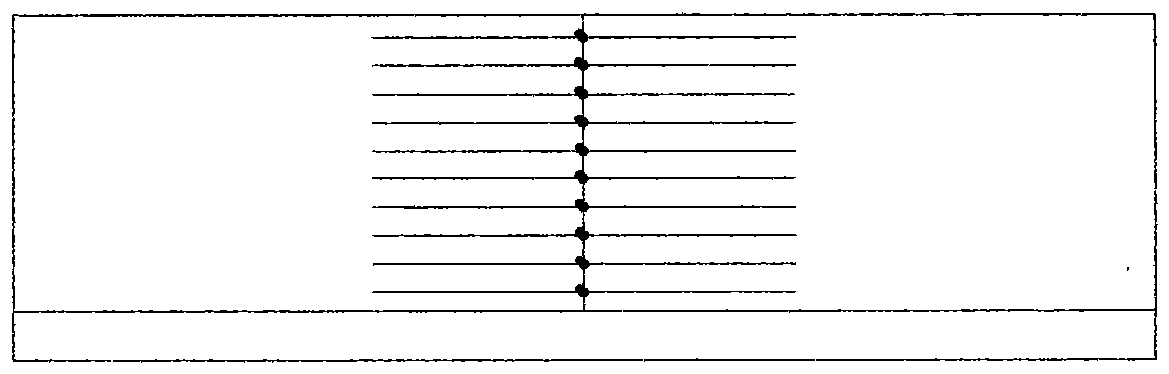

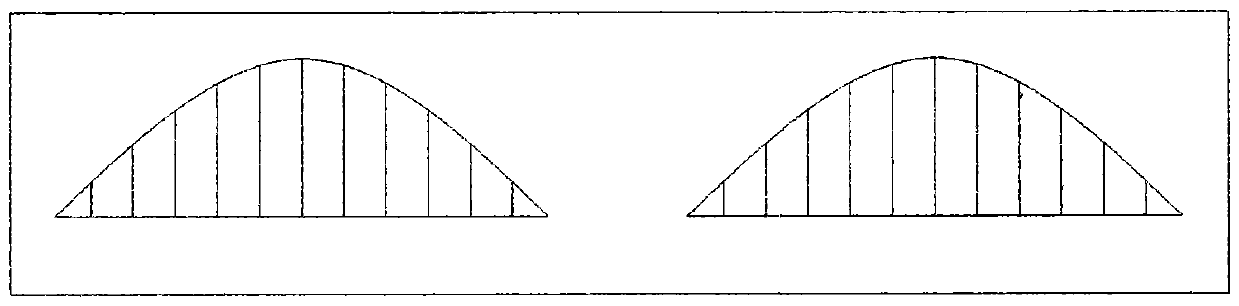

[0034] Such as Figure 5 As shown, in the existing processing method of arc-toothed cylindrical gear, the axial section tooth profile of the tool is the same as the end face tooth profile of the standard straight rack cutter, but the tool is a disc-shaped tool, that is, the ring surface of the normal tooth profile around its axis . The machining process is that the tool rotates around its own axis ω c , and at the same time the center of the tool is translated v in the horizontal plane c , the processed gear rotates around its own axis ω 2 , ω 2 with v c Constitute the developing motion, ω c For cutting motion, since the cutting motion is performed by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com