Method for realizing continuous regulation of primary pump variable flow system by using evaporative water cooling machine set

A chiller and variable flow technology, applied in heating and ventilation control systems, heating and ventilation safety systems, applications, etc., can solve problems such as the inability to adjust the frequency of a single circulating pump, the difficulty of saving energy consumption for transportation, and the inability to adjust the flow of water pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

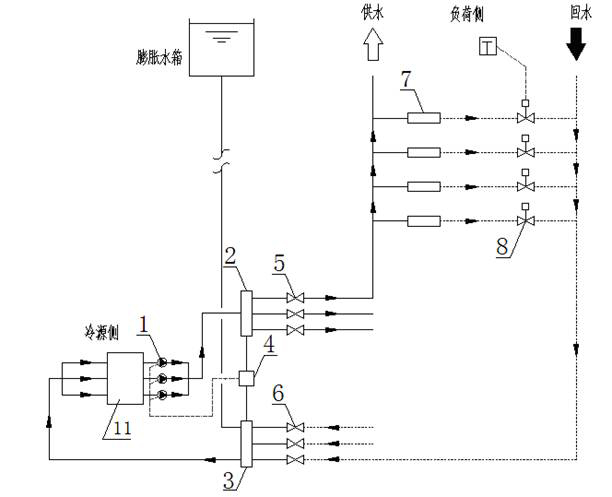

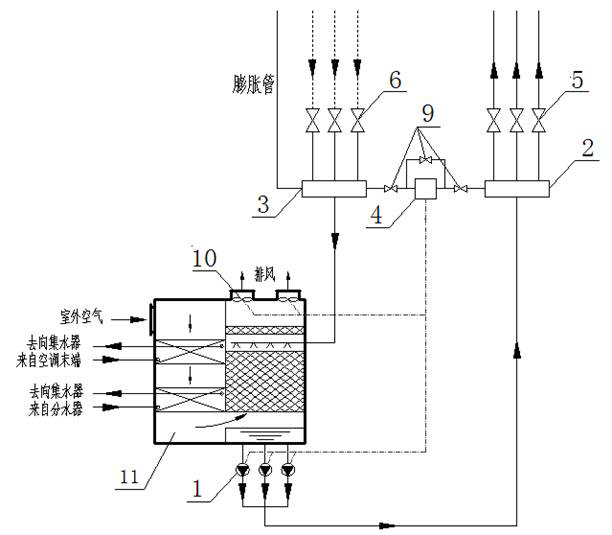

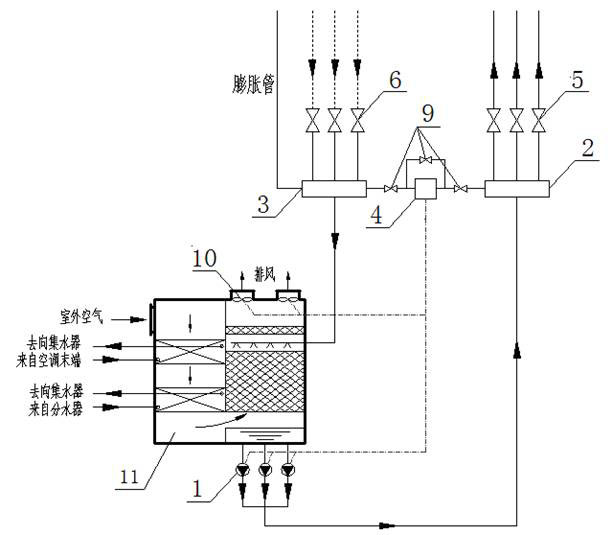

[0014] The primary pump variable flow system is composed of the cold source side and the load side connected through the pipe network. The cold source side includes the cold source and multiple circulating pumps 1, and the load side includes the connected water separator 2 and valves in sequence according to the water flow direction. a5, air conditioner terminal 7, electric two-way valve 8, valve b6 and water collector 3. The method of the present invention is characterized in that the evaporative chiller 11 is used as the cold source of the primary pump variable flow system, and the pressure difference controller 4 is connected in series between the water separator 2 and the water collector 3, so that the pressure difference controller 4 is respectively It is connected with the fan 10 of the evaporative chiller and the circulation pump 1 sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com