Container ship propeller double-sleeve energy-saving device

A technology for container ships and energy-saving devices, which is applied in the construction of transmissions, hulls, and ships using synchronous propulsion components, which can solve problems such as wasting energy, changing the state of bubbles, and resistance, and achieve the effects of reducing contact area and frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

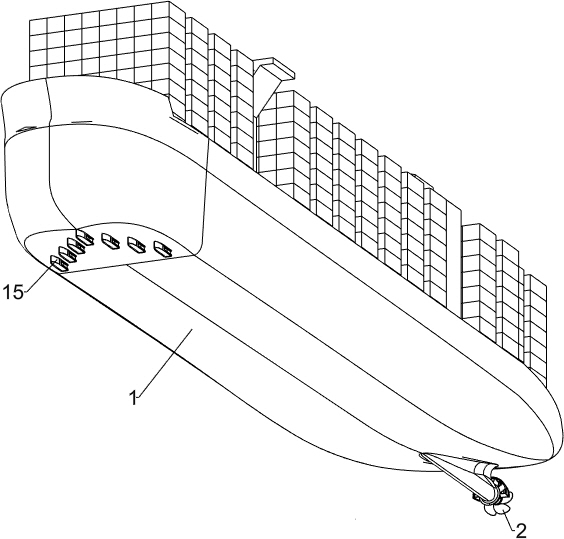

[0029] A container ship propeller double-set energy-saving device, such as Figure 1-Figure 9As shown, it includes a high-efficiency propeller 2, and the high-efficiency propeller 2 is sealed and rotatably installed at the stern of the container ship 1. The stern of the container ship 1 is provided with a stern seal installation part, and the rotating shaft of the high-efficiency propeller 2 passes through the stern seal installation part. The stern The sealing installation part is provided with a front energy-saving part. The stern sealing installation part is used for the high-efficiency propeller 2 and the energy-saving part to be installed together. The front energy-saving part is used for uniform inflow of the high-efficiency propeller 2. With the coordination of energy-saving components, the inflow state of the front energy-saving components can be adjusted to produce different flow equalization effects at different speeds. The lower side of the front part of the containe...

Embodiment 2

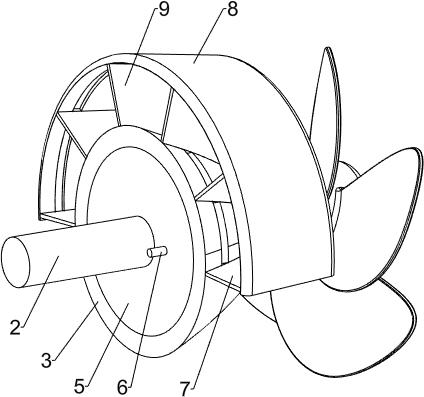

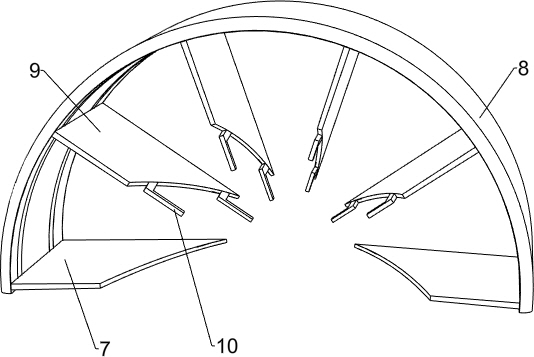

[0032] On the basis of Example 1, as figure 2 and Figure 4 As shown, the stern sealing installation component includes a stern installation shell 3, which is fixedly arranged at the stern of the container ship 1, and the upper part of the stern installation shell 3 is provided with two limit chutes. The openings of the limit chutes are all set backward, and the limit chutes open to the rear prevent the water flow from producing resistance to the stern mounting shell 3. The shape of the stern mounting shell 3 is set to a streamline shape that decreases from front to back, so that Reduce the influence of the stern water flow on the hull movement, make the force at the stern even and ensure the dispersion of the force, the rear part of the stern installation shell 3 is fixedly connected with a sealing casing 4, the sealing casing 4 and the shaft of the high-efficiency propeller 2 Rotating connection, the front part of the stern installation shell 3 is fixedly installed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com