High-precision balance for measuring resistance of water tunnel

A high-precision, balance technology, applied in the field of high-precision water tunnel resistance measurement balance, can solve the problems that the accuracy is greatly affected by the ambient temperature and humidity, the requirements are high, and the accuracy cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

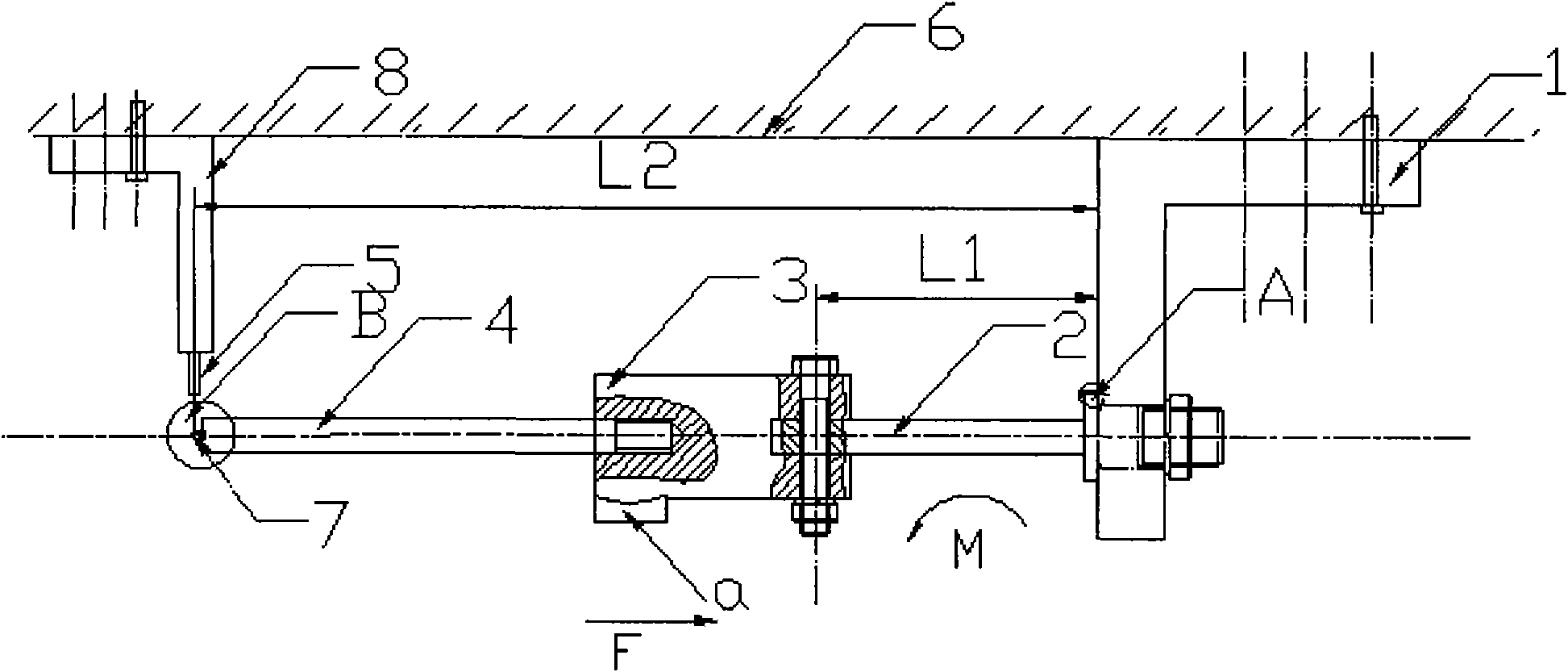

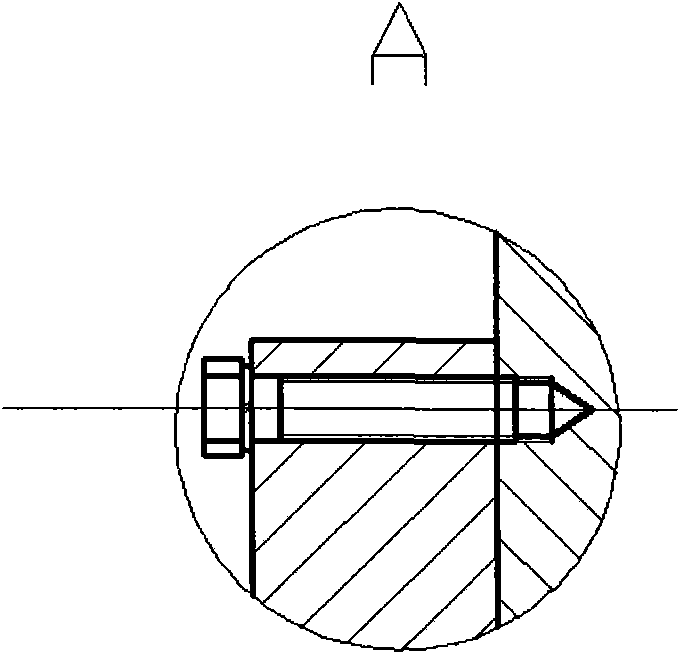

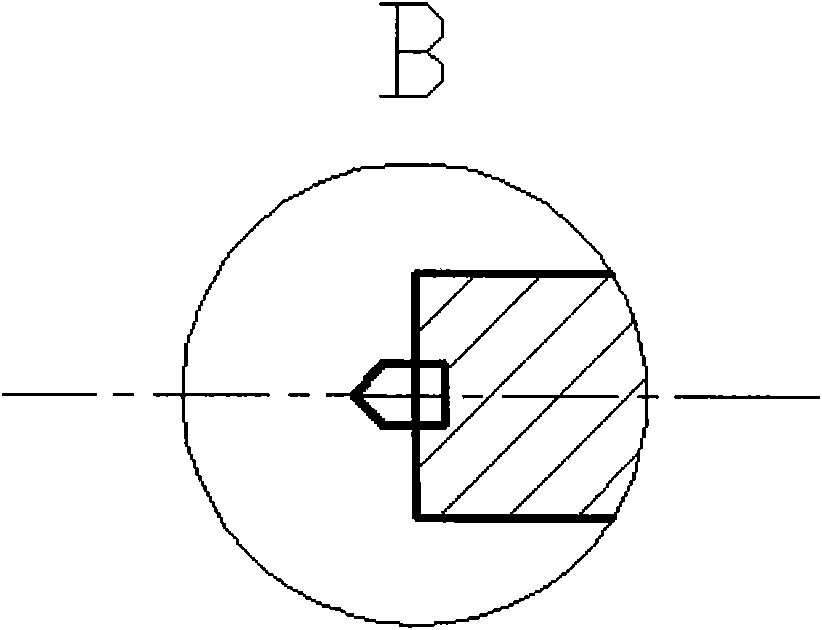

[0018] figure 1 It is a schematic diagram of the high-precision water tunnel resistance measurement balance of the present invention. The resistance measurement balance support 1 and the sensor support 8 are inverted L-shaped, the material is 2Cr13 stainless steel, and they are connected to the water hole cover plate 6 through four M8 bolts distributed in a circular array. The elastic deformation beam 2 is processed by No. 45 steel, and the studs of 30×M20 are processed on the right side of the platform stage with a diameter of 28 mm and a length of 5 mm at its right end, and the M20 studs at the right end of the elastic deformation beam 2 pass through the balance bracket 1 for 20 through the through hole, and fasten the connection with the through hole of φ20 on the balance support 1 through the nut of M20. The resistance measured by this balance is in the horizontal direction. In order to avoid the interference of forces in other directions, the left end of the elastic def...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com