Fire-resistant oil purification treatment method and device thereof

A technology for purification treatment and fire-resistant oil, which is applied in the separation of immiscible liquids, etc., and can solve the problems of poor thermal stability and hydrolysis stability, unsatisfactory dispersion, residence time and flow pattern, and deterioration of anti-flammable liquids.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

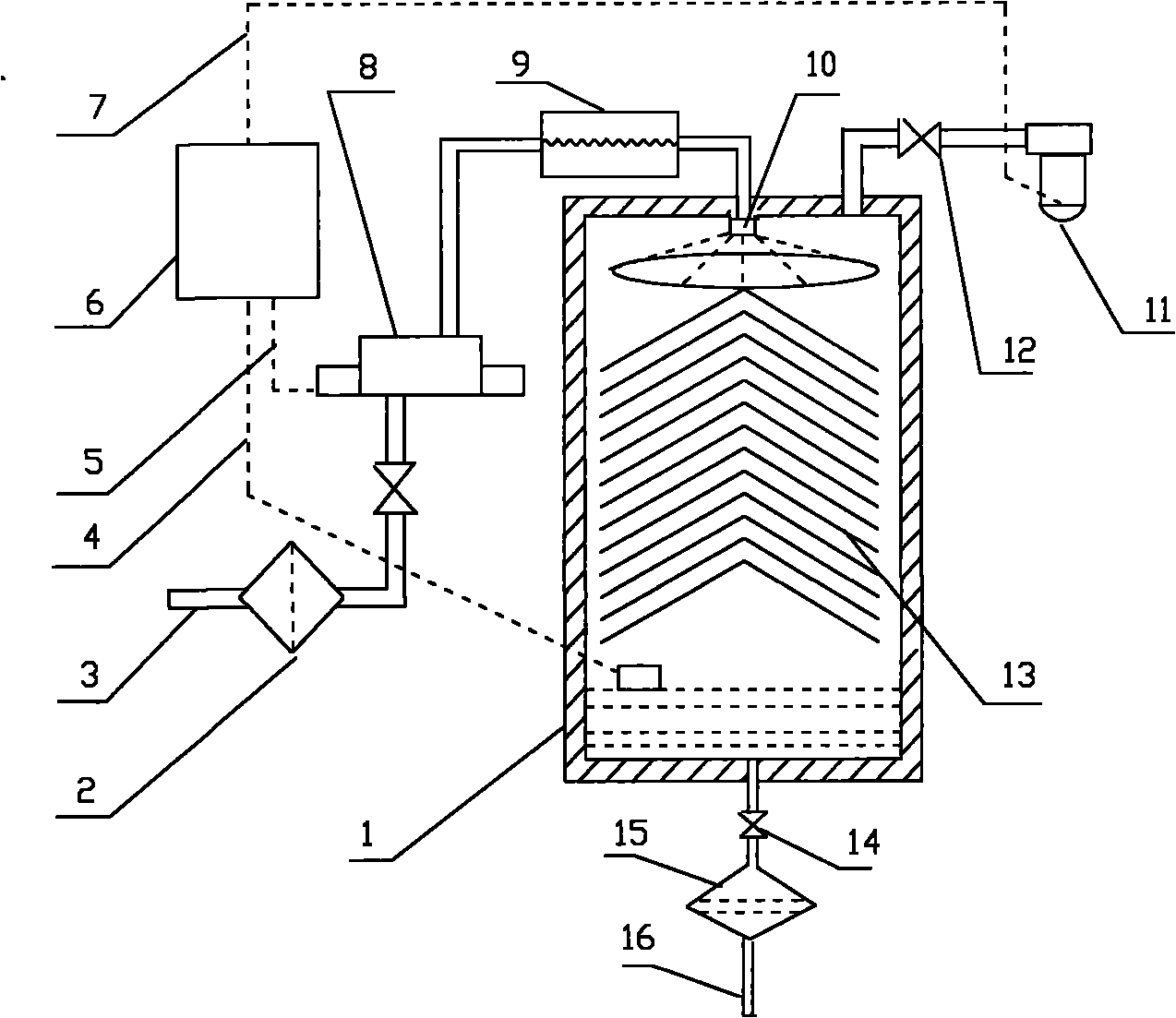

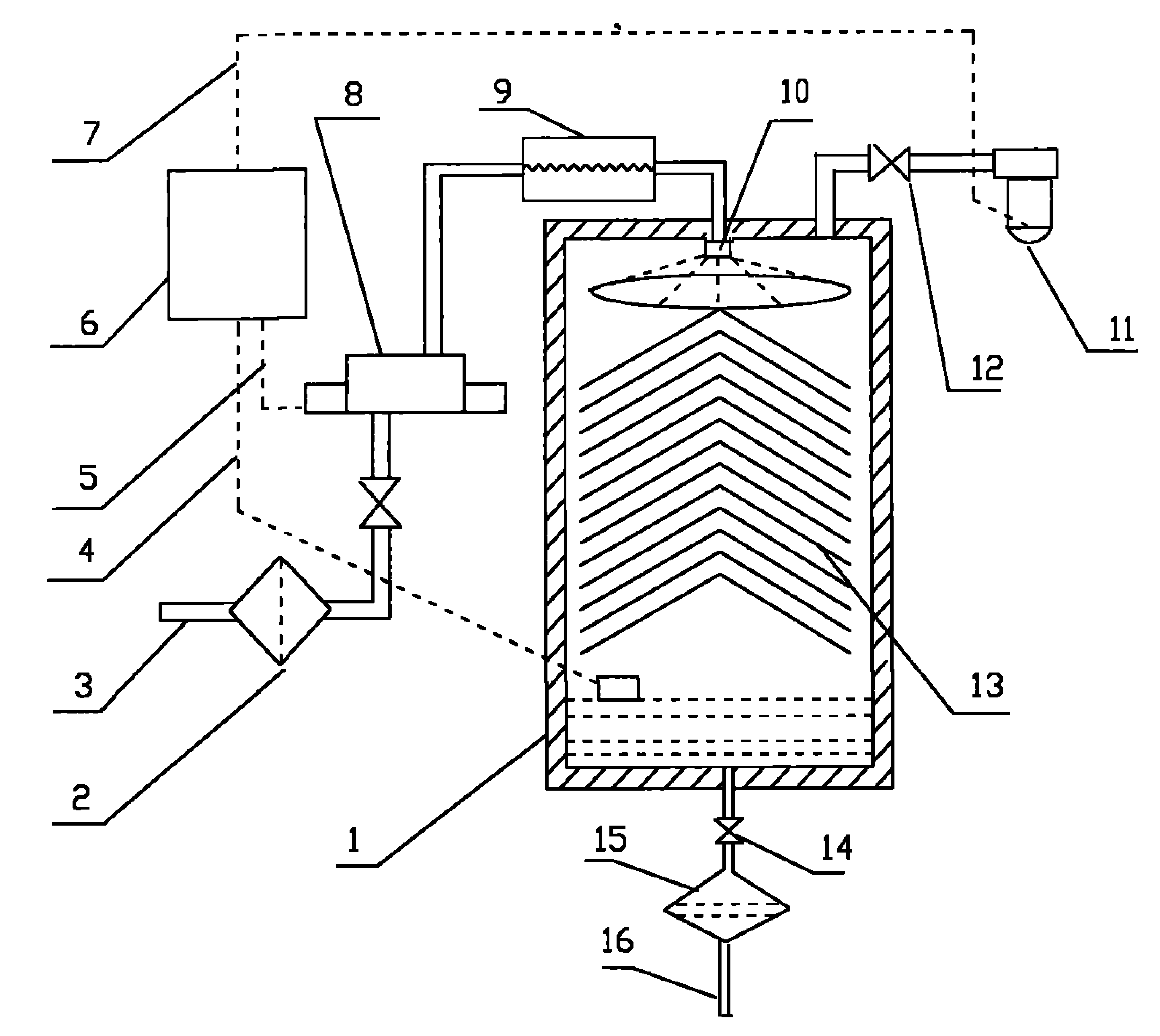

[0010] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0011] Such as figure 1 As shown, start the drive pump, and the anti-fuel oil to be treated passes through the coarse filter 2 from the oil inlet pipe to filter out large particles of mechanical impurities, and then passes through the electromagnetic flow valve 8 to obtain a certain flow rate, and then passes through the heater 9 for proper temperature rise, and then enters the The spray distributor 10 above the separation tank body 1 forms atomized fine liquid droplets, which are sprayed on the conical separation tray 13. Due to the different specific gravity of the anti-fuel oil and water, the binding force of oil and water in the fine liquid droplets decreases. When When the oil passes through the trays step by step from top to bottom, the fine and dispersed water droplets converge toward the top of the cone in the separation tank, and beco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com