Emulsion breaking device for realizing emulsified oil by using vortex shearing

A demulsification device and technology for emulsified oil, applied in the direction of immiscible liquid separation, etc., can solve problems such as loss of original function, inability of running oil to flow smoothly, and acceleration of oil quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

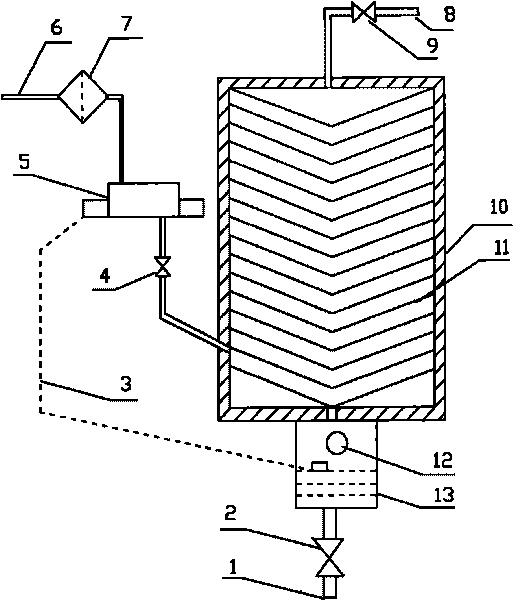

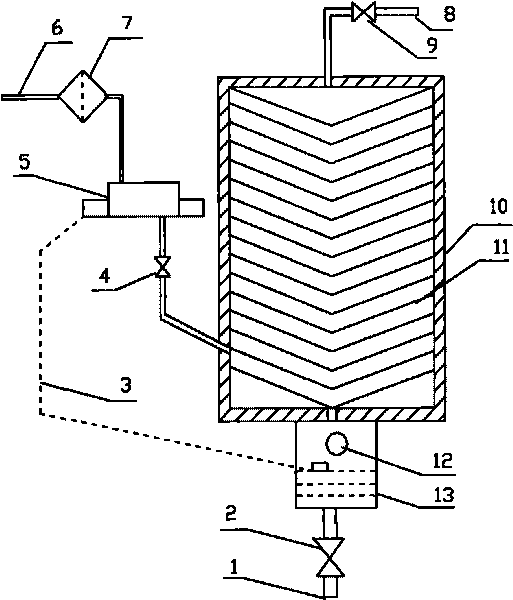

[0010] The technical scheme of the present invention for the demulsification treatment of emulsified oil will be described in detail below in conjunction with the accompanying drawings.

[0011] like figure 1 As shown, start the drive pump, the oil to be demulsified is filtered from the oil inlet pipe 6 through the coarse filter 7 to remove large particles of mechanical impurities, and then through the electromagnetic flow valve 5 to obtain a certain flow rate, and then enters the separation tank below the separation tank 10 in an eccentric manner. In the vortex shearing separation orifice plate 11, the slight centrifugal effect only deforms the emulsion film without making the oil muddy; due to the vortex shearing effect, the binding force between oil and water decreases, and the specific gravity of oil and water is different , when the vortex-like oil passes through the orifice plate step by step from bottom to top, the fine and dispersed water droplets are sinking, and are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com