Connector having lock mechanism for keeping socket and a header coupled, and method for manufacturing the connector

A locking mechanism and connector technology, applied in fixed connection, two-part connection device, connection, etc., can solve the problems of increased number of steps, complicated structure of head 42, flatness damage of head contact 47, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A connector configuration according to an embodiment of the present invention, which is provided with a locking mechanism for maintaining a receptacle and a head in a combined state, will first be described with reference to the accompanying drawings. It should be understood that the following descriptions do not limit the scope of the present invention, but are intended to increase understanding of the embodiments of the present invention.

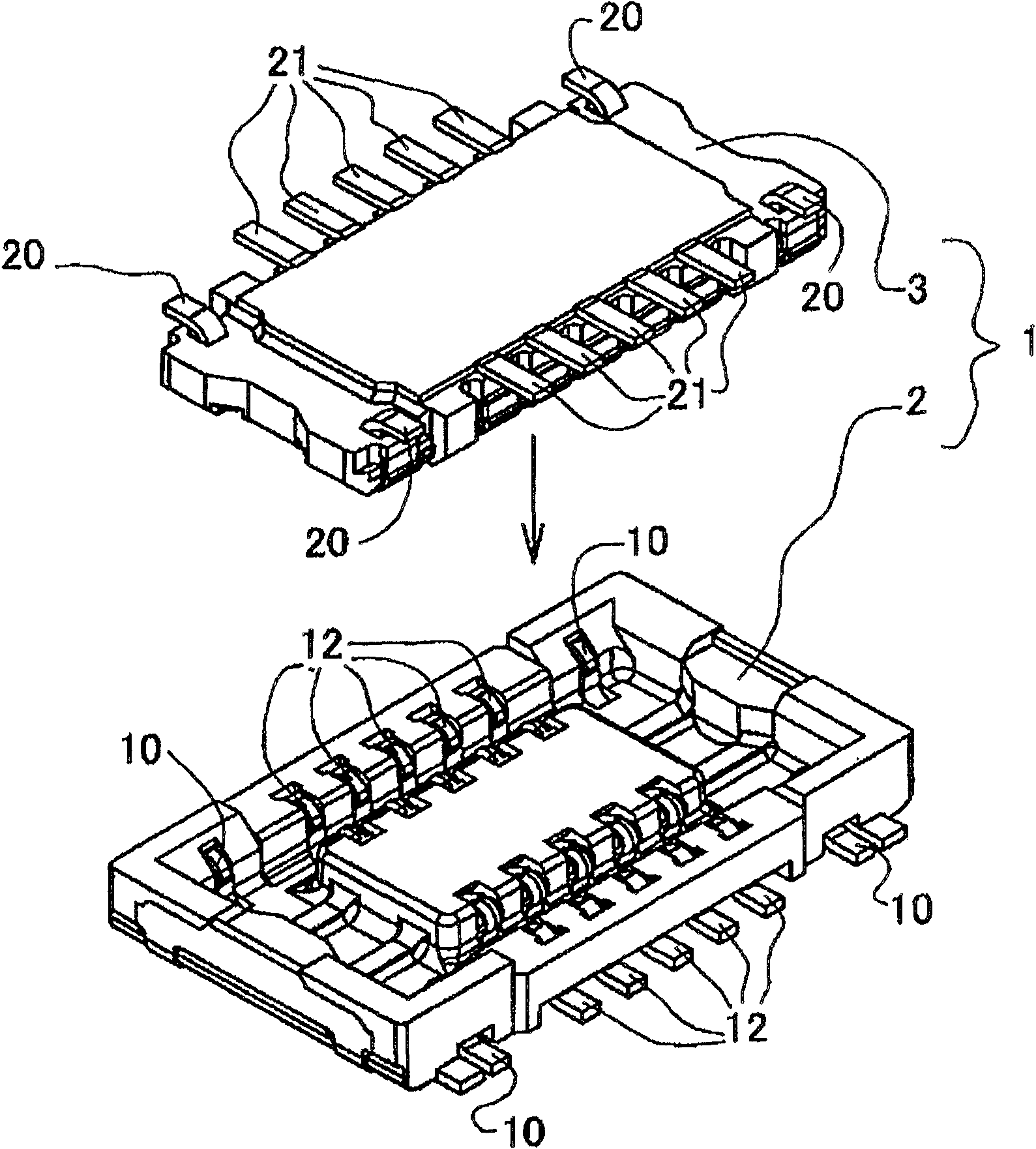

[0031] see figure 1 , the connector 1 according to the embodiment of the present invention includes a receptacle 2 and a head 3 . The first thing to introduce is the structure of the socket 2 and the head 3, and then the method of combining them will be introduced.

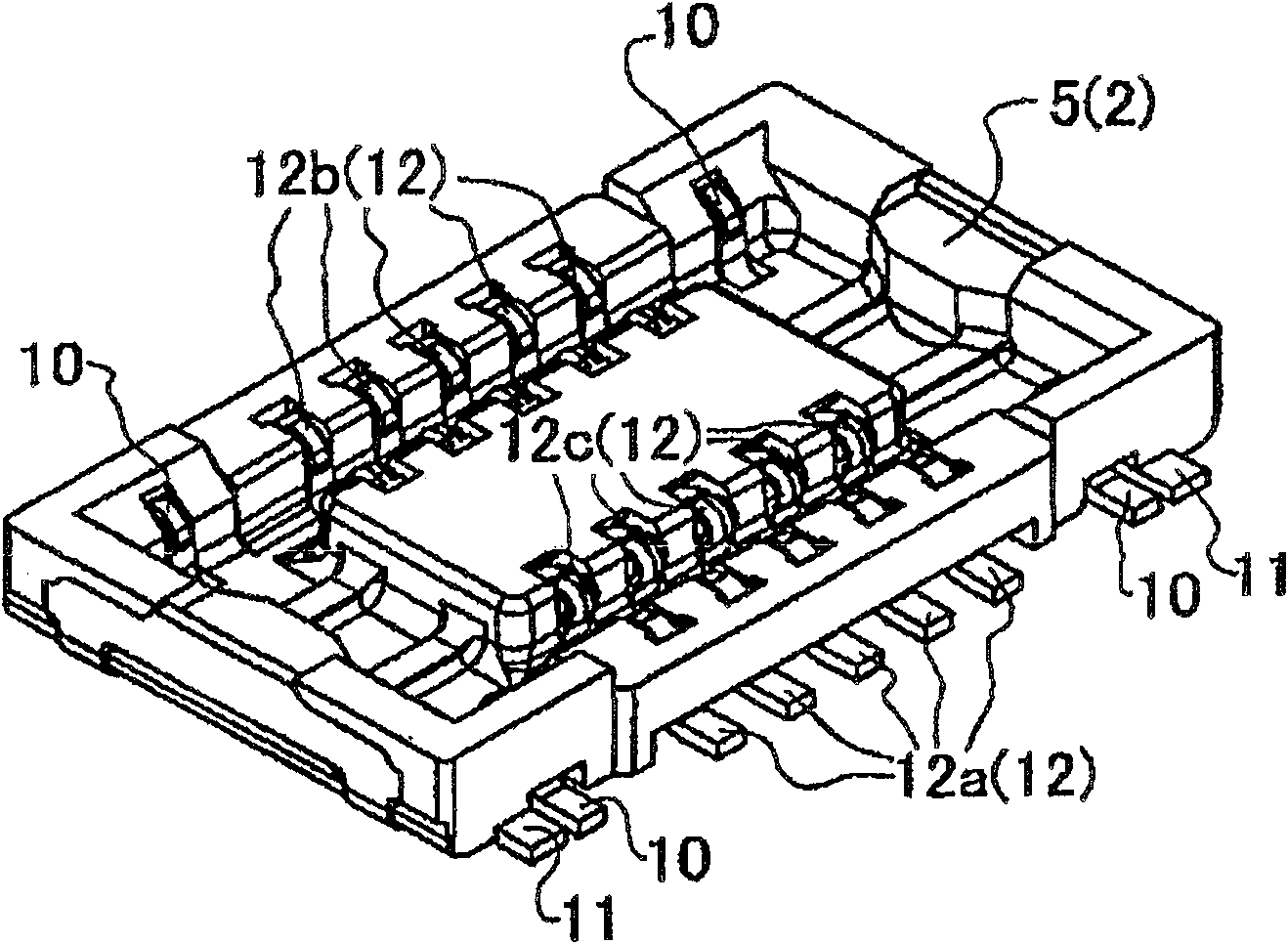

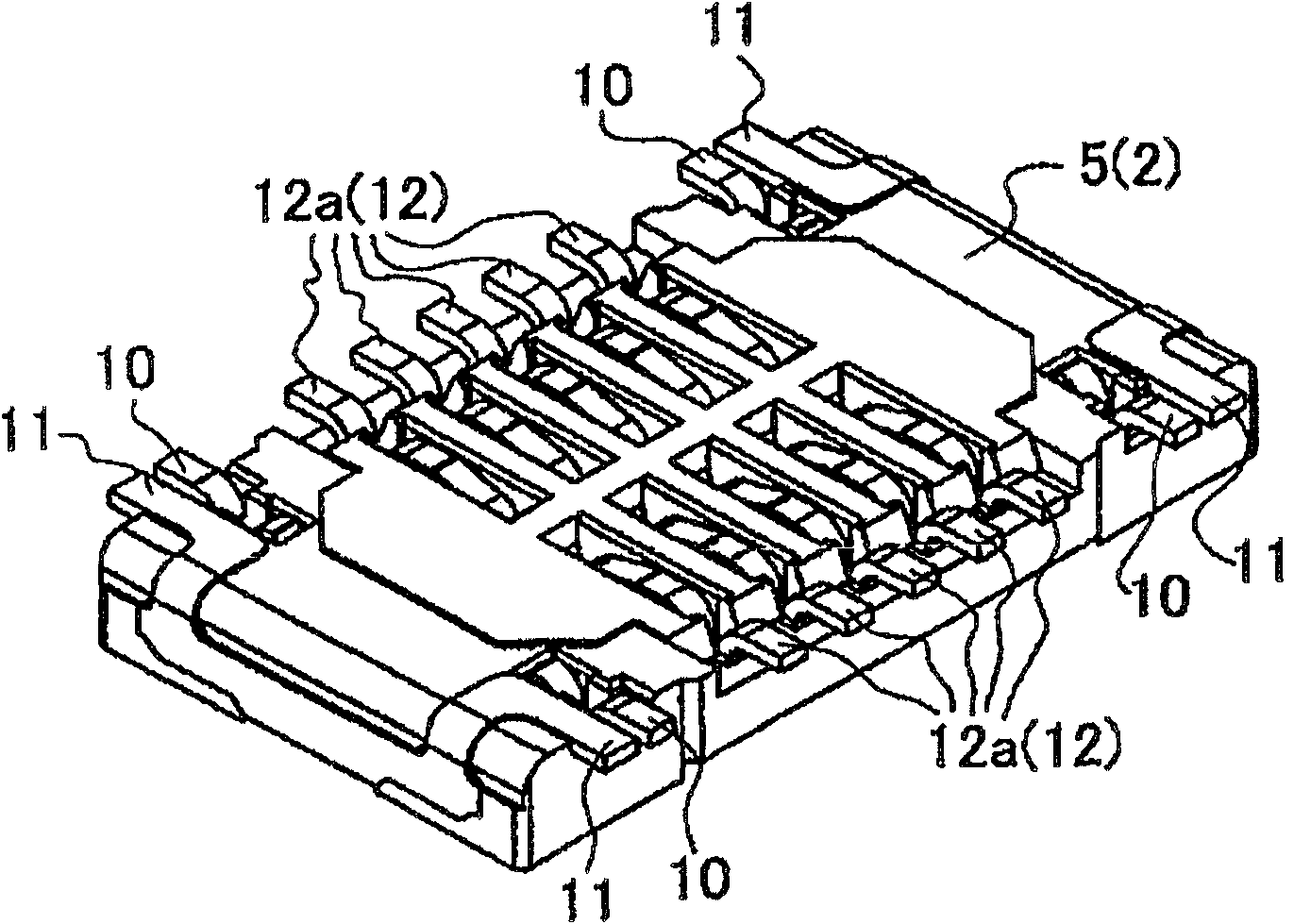

[0032] Outlet 2 will be introduced first. Figure 2A draws the front side of receptacle 2, while Figure 2B Its rear side is drawn. The socket 2 includes a socket main body 5 , a latch (lock mechanism) 10 on the socket side, a retainer portion (retainer mechanism)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com