High-pressure water spray end equipment

A terminal device, high-pressure water technology, applied in the direction of spray device, spray device, liquid spray device, etc., to achieve the effect of improving human comfort and improving cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present invention is applied on the 10m platform of the World Expo axis in the World Expo area, and 73 spraying devices are arranged in total.

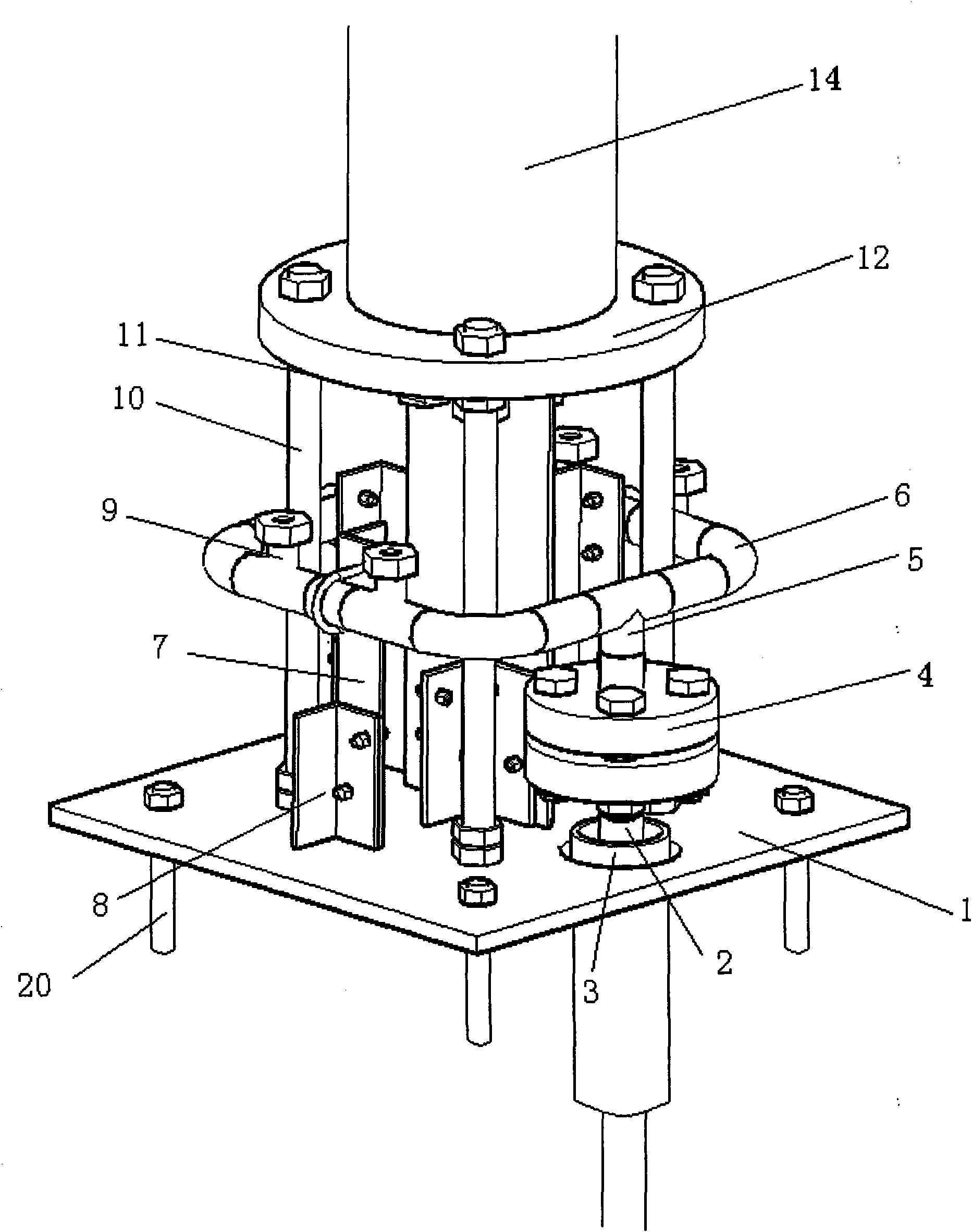

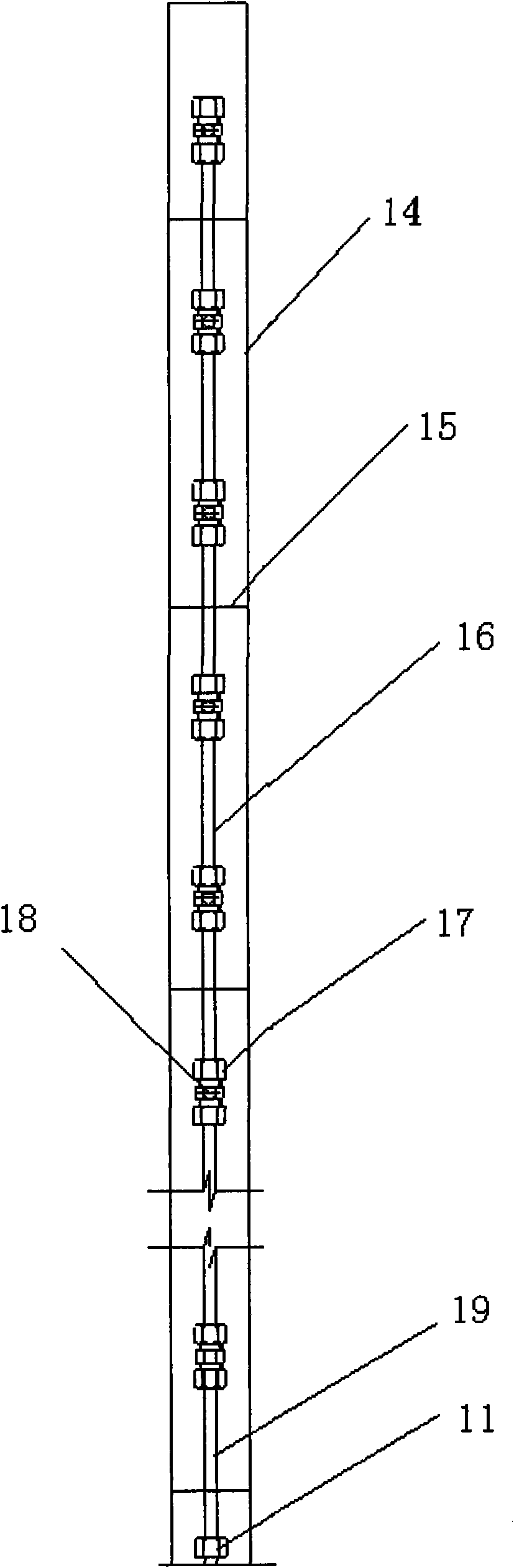

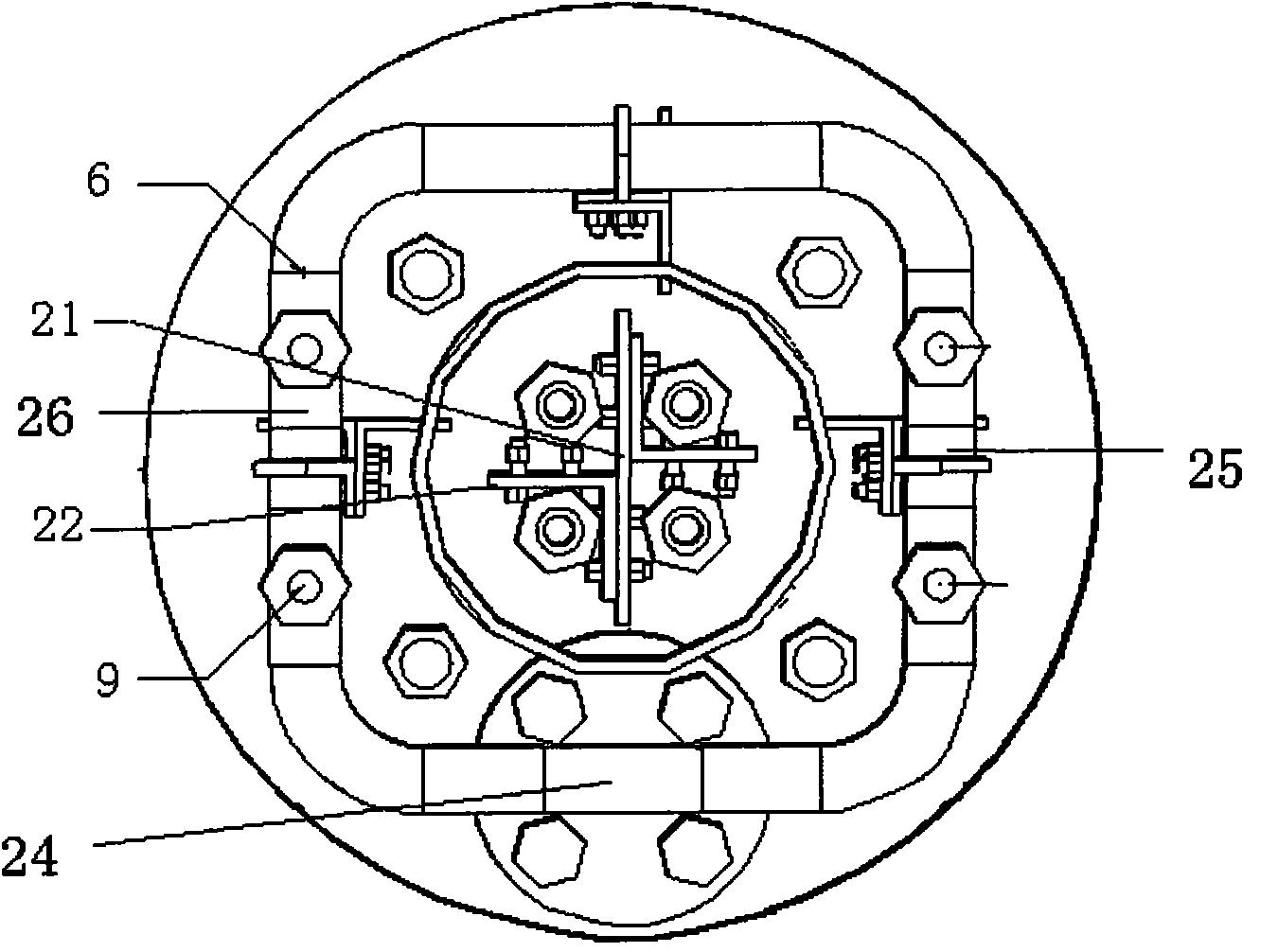

[0027] like figure 1 , 2 As shown, it includes a base plate 1, a platform 23 and a pipe network. There is a square hole under the platform 23. The base plate 1 is installed on the waterproof layer of the square hole. There is a round hole on one side of the base plate 1, and four Four fixing bolts 20 are installed on each corner, and the steel pipe 2 in the pipe network passes through the round hole on the bottom plate 1 to be connected with the pipe flange 4, and the pipe flange 4 is connected to the square ring pipe through the first three-way pipe 5. The front side 24 of 6 is connected, and the other three sides of the square ring pipe 6 are respectively fixed on three first steel plates 7, and the three first steel plates 7 are respectively fixed with three first steel angles 8 by bolts. Even, the three first steel an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap