Power generating guide rail

A technology of guide rails and sleepers, applied in the field of rail car guide rails, can solve the problems of multiple steel materials, increased costs, and high laying costs, and achieve the effect of broad application prospects and outstanding benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

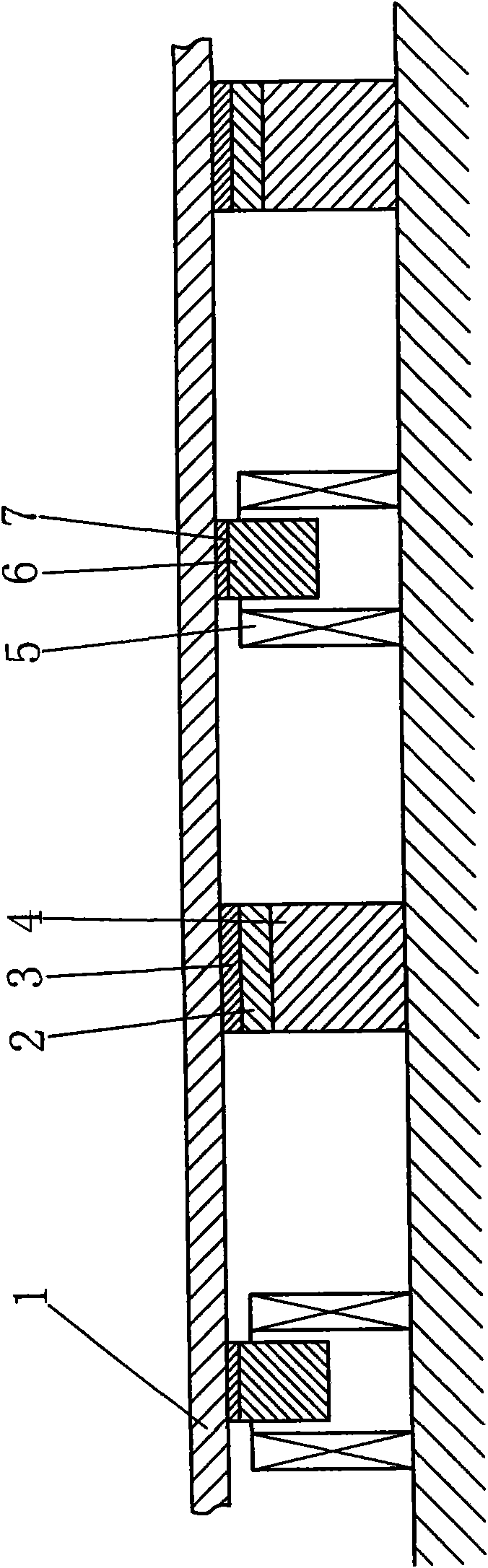

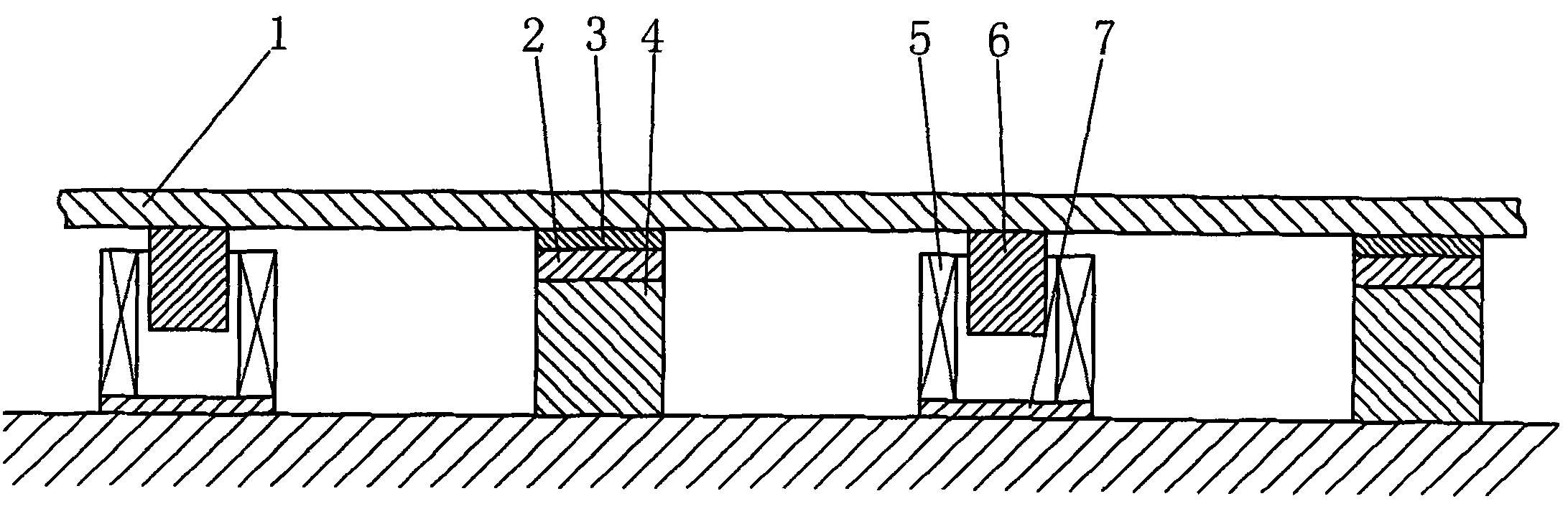

[0011] Example: such as figure 1 As shown, the support 4 is fixed on the roadbed, the piezoelectric body 2 is connected on the top of the support 4, and the insulating pad 3 is placed on the upper end surface of the piezoelectric body 2, and the support 4, the piezoelectric body 2, and the insulating pad 3 form a piezoelectric sleeper. The guide rail 1 is placed on the upper end surface of the insulating pad 3 and fixed with the support 4; a certain distance away from the piezoelectric sleeper along the road length direction, the non-magnetic block 7 is connected under the guide rail 1, and the magnetic block 6 is connected under the non-magnetic block 7 , the coil 5 is sleeved outside the magnetic block 6 with a gap, the lower end surface of the coil 5 is fixed on the roadbed, the coil 5, the magnetic block 6, and the non-magnetic block 7 form an induction generating unit; the piezoelectric sleeper and the induction generating unit are along the guide rail 1 are arranged alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com