Special gear oil for shield and preparation method thereof

A gear oil and shield technology, applied in the field of lubricating oil, can solve the problems of large impact force of shield bearing gear, fluctuation of bearing gear torque, affecting the smooth excavation of the shield, so as to achieve good protection, improve extreme pressure performance, and smooth excavation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] The preparation method of boron nitride after surface treatment:

[0057] Mix boron nitride with bis-succinimide dispersant, stir and disperse at 63°C for 50 minutes, and then grind the obtained mixture with a ball mill for 48 hours to obtain surface-treated boron nitride;

[0058] Boron nitride: bis-succinimide = 1: 1.5, weight ratio;

[0059] The resulting product did not require isolation and had an average particle size of 85 nm.

Embodiment 1

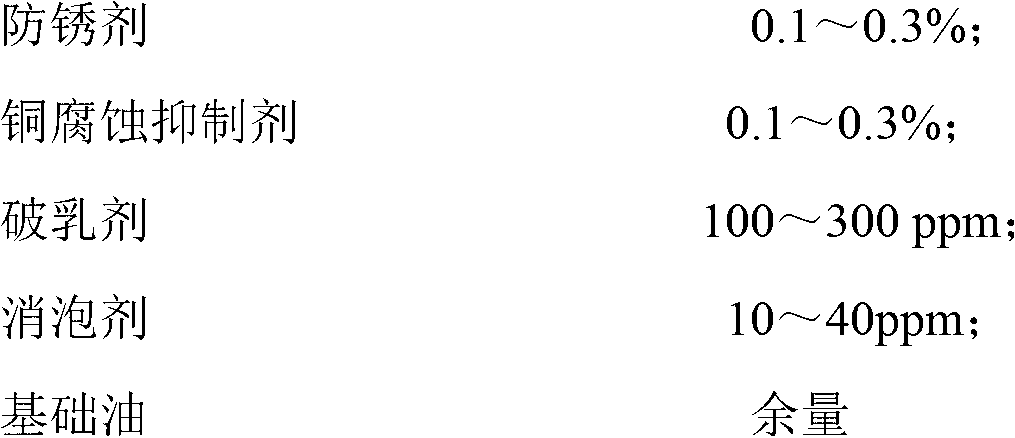

[0061]

[0062]

[0063] In the preparation method, each component is mixed and stirred evenly to obtain the product.

[0064] Test results:

[0065]

Embodiment 2

[0067] The boron nitride after surface treatment is the same as in Example 1.

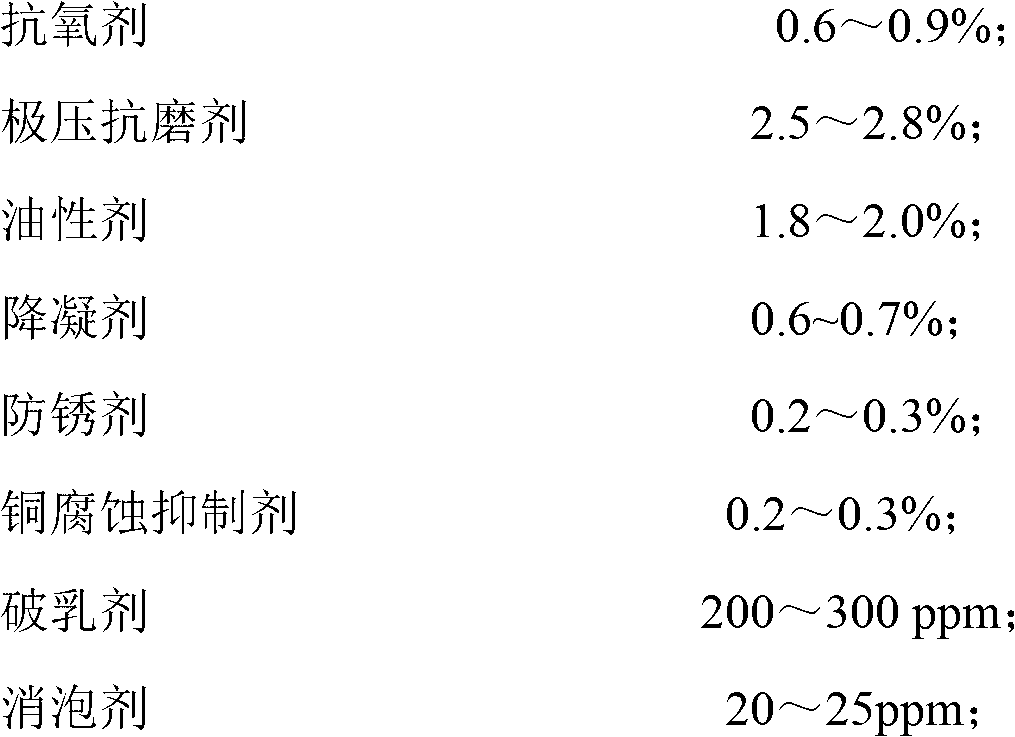

[0068]

[0069]

[0070] Test results

[0071]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com