Controller for diesel engine and method of controlling diesel engine

A technology of diesel engine and control device, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problems of fuel ignition timing delay, misfire, and combustion state deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

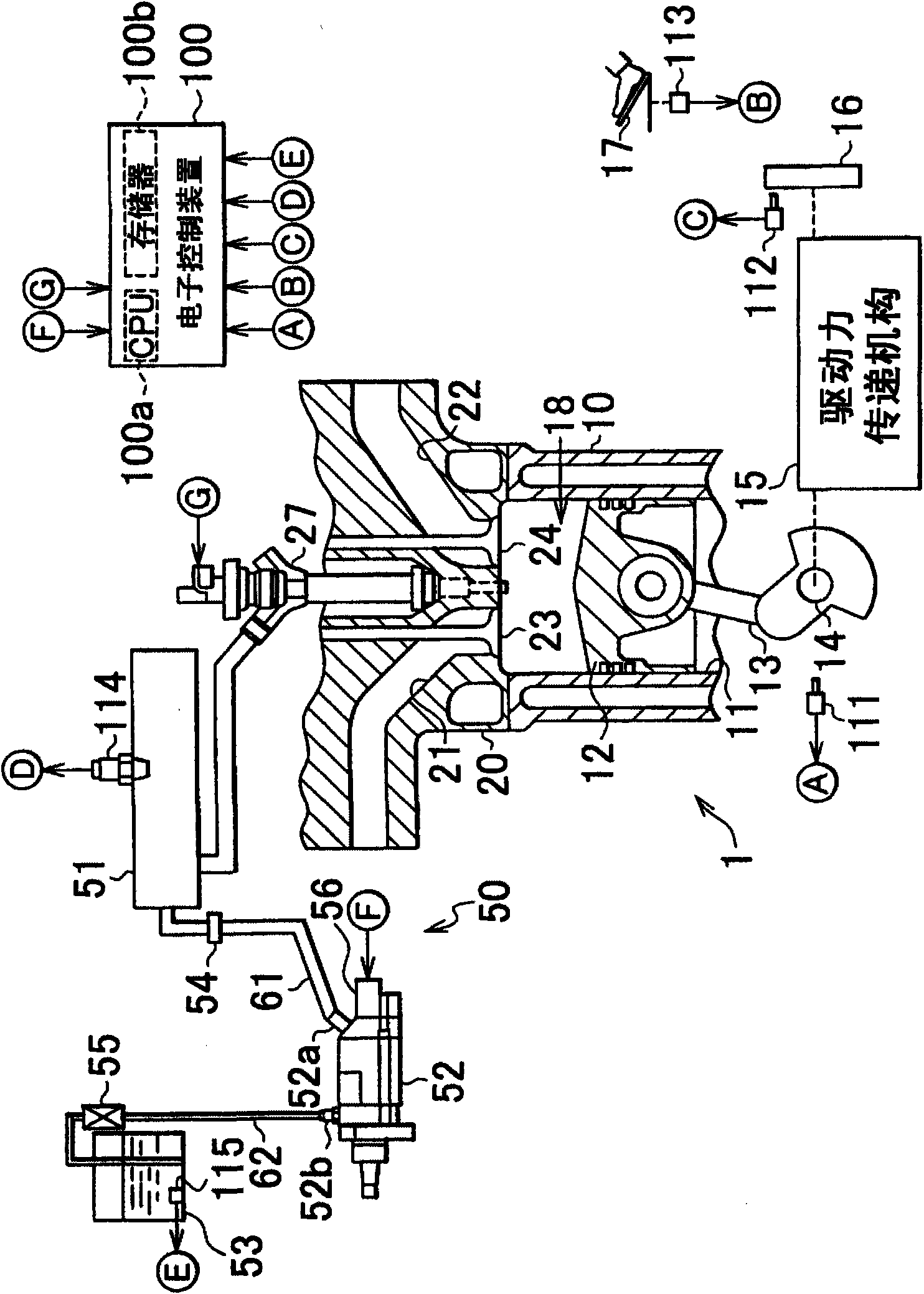

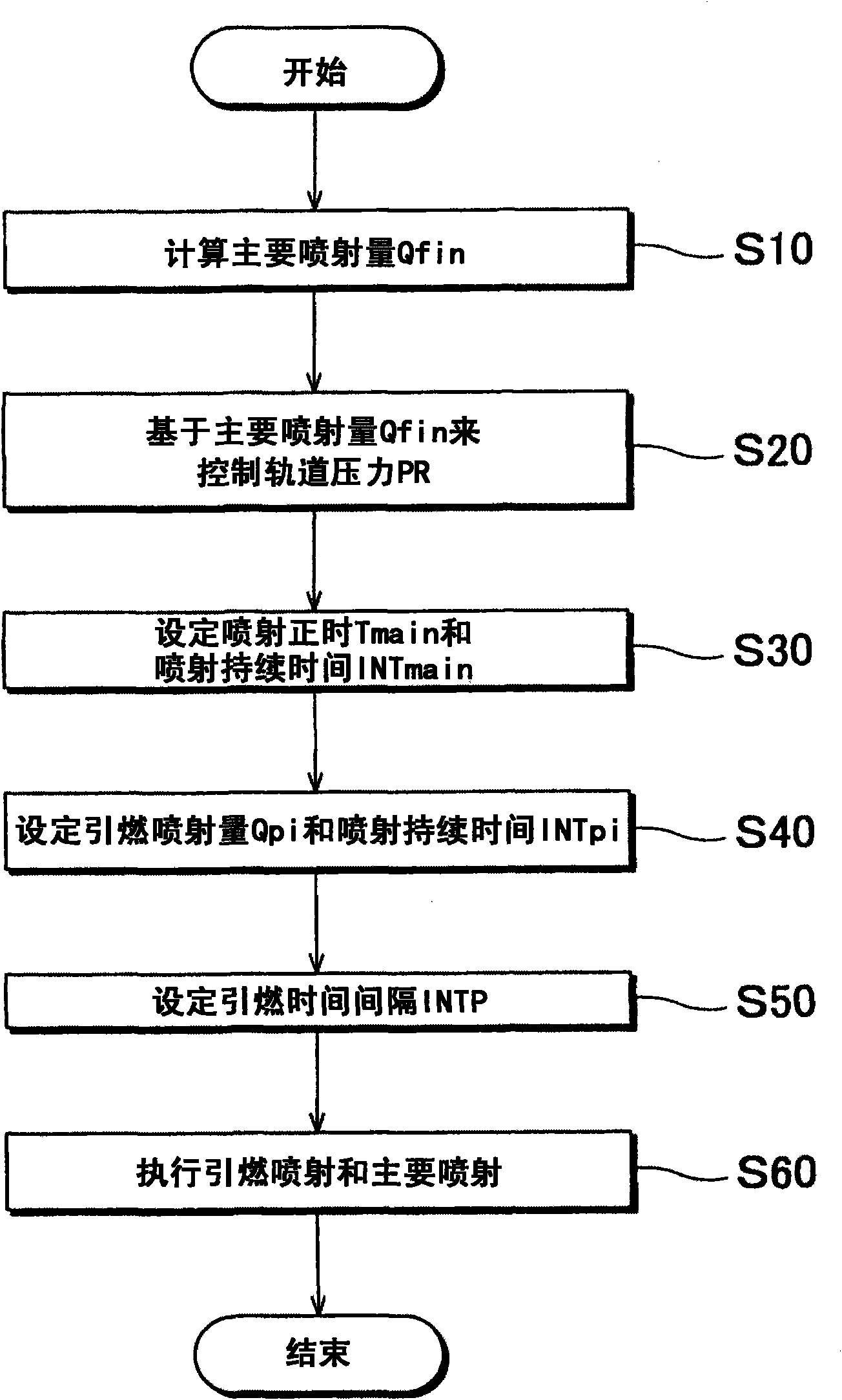

[0045] One embodiment in which the present invention is applied to a control device for a diesel engine for a vehicle will be described with reference to FIGS. 1 to 9 . FIG. 1 schematically shows a diesel engine mounted on a vehicle and a control device for the diesel engine. As shown in FIG. 1 , a cylinder block 10 of a diesel engine 1 has a plurality of cylinders 11 formed therein, wherein one cylinder among the plurality of cylinders is shown in FIG. Reciprocating piston 12. Piston 12 is connected to crankshaft 14 via connecting rod 13 . When the vehicle is running, the torque of the crankshaft 14 is transmitted to the driving wheels 16 through the driving force transmission mechanism 15 . The driving force transmission mechanism 15 is constituted by a transmission, a differential gear unit, a drive shaft, and the like.

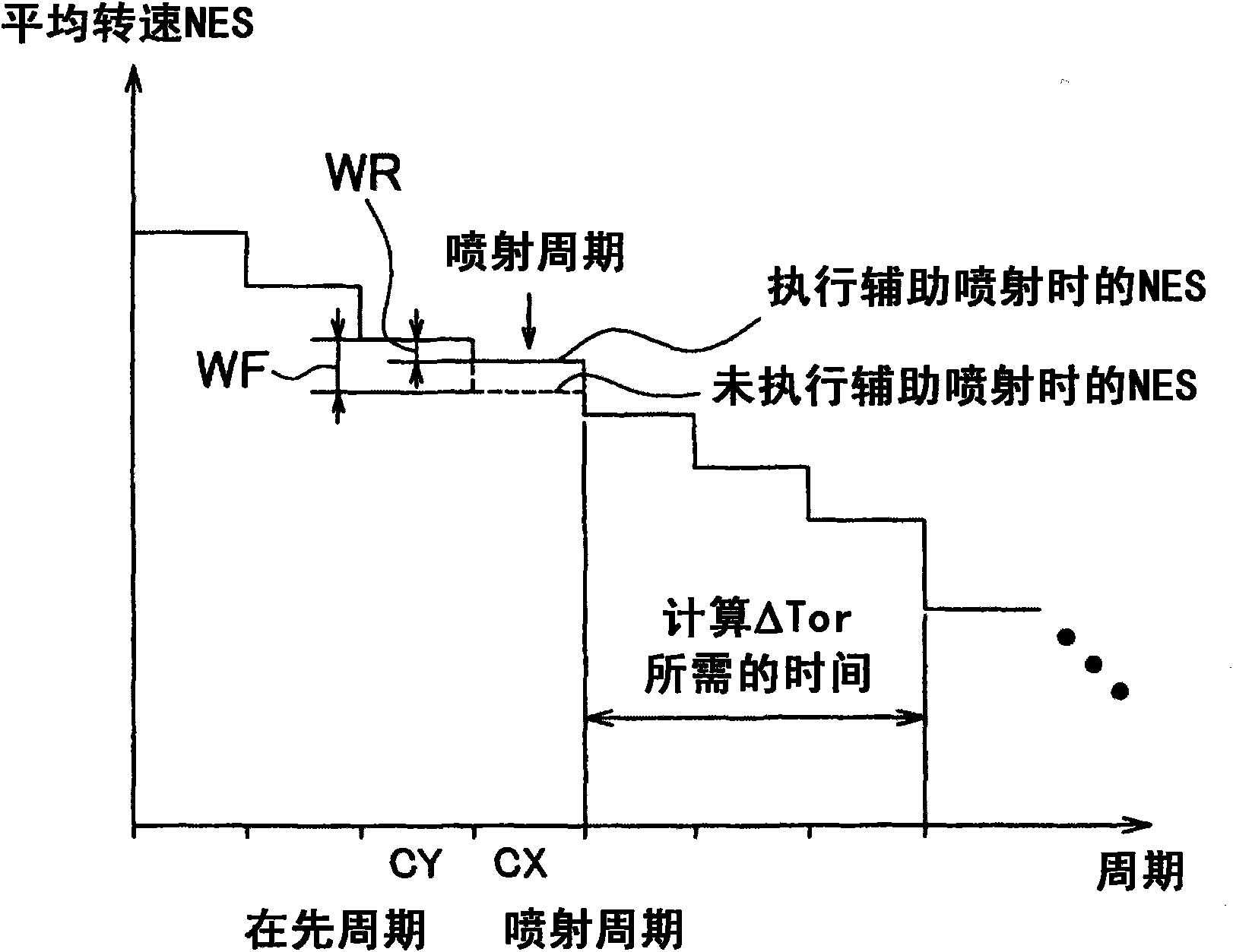

[0046] A crank sensor 111 for detecting the rotational speed of the crankshaft 14 (hereinafter simply referred to as "engine rotational speed NE") is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com