Method for improving fireproof performance of vehicle body

A car body and performance technology, applied in railway car body parts, fire rescue, aerodynamic improvement and other directions, can solve the problems of inability to evacuate, burn the whole vehicle, property damage, etc., and achieve less cost and property loss. , the effect of reducing the risk of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

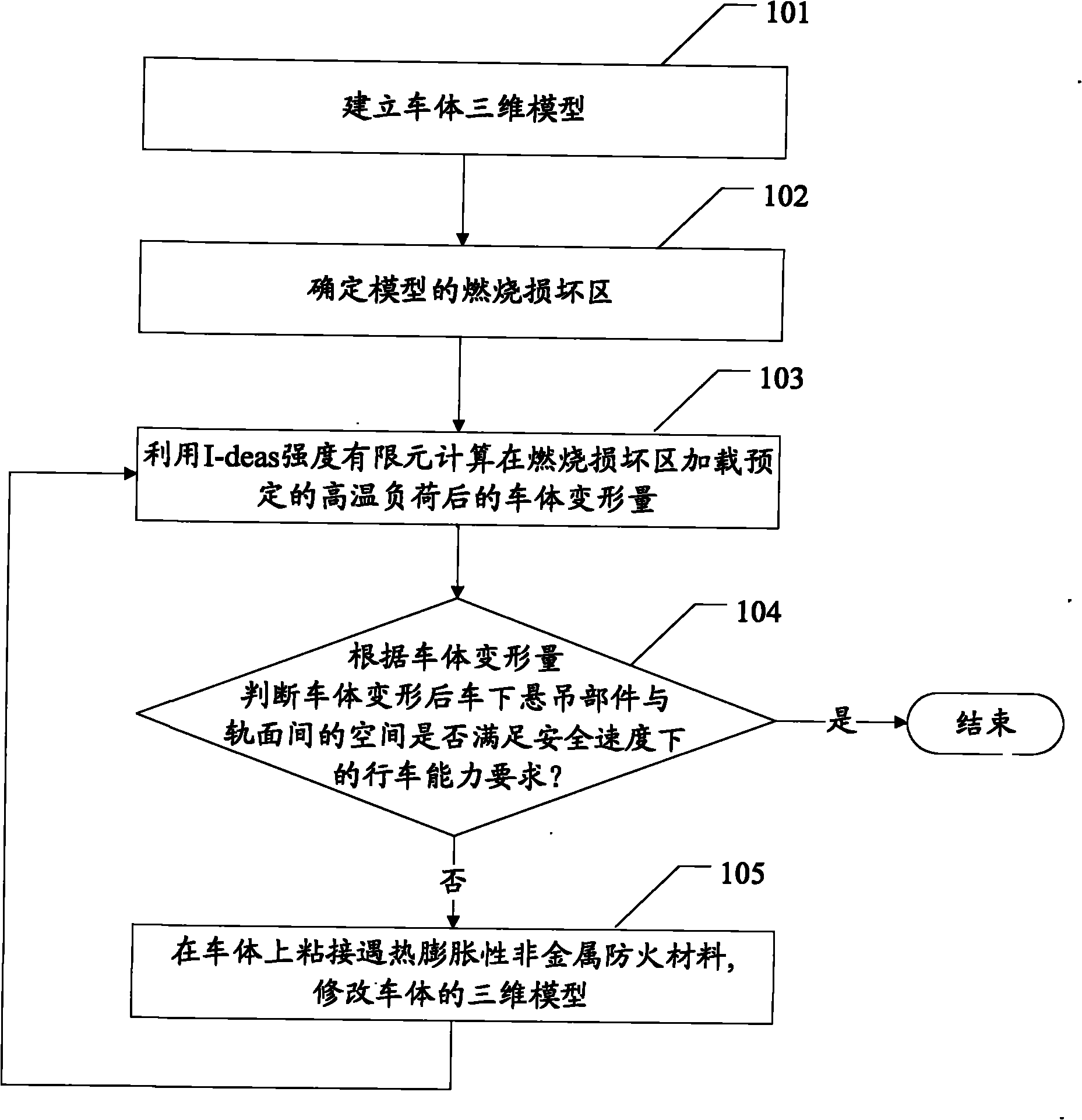

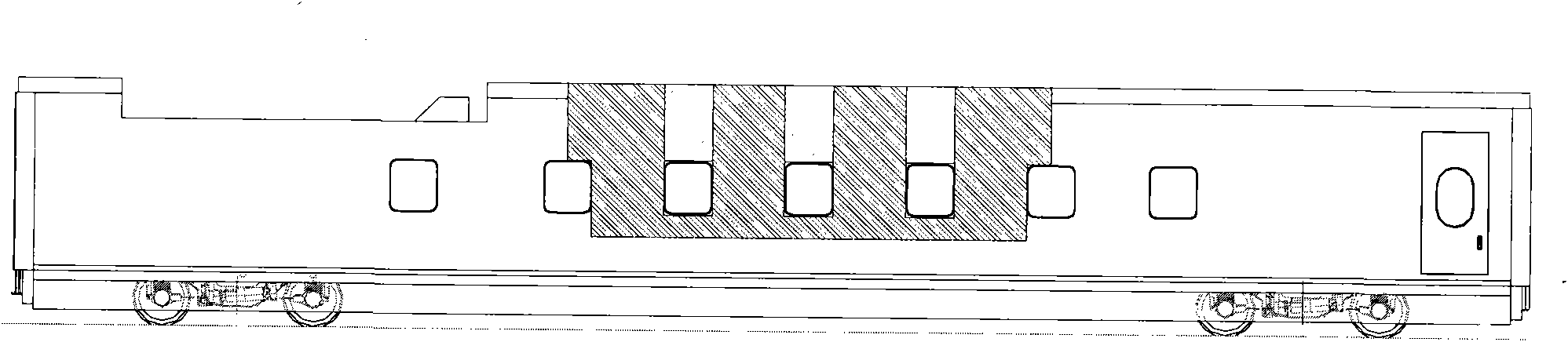

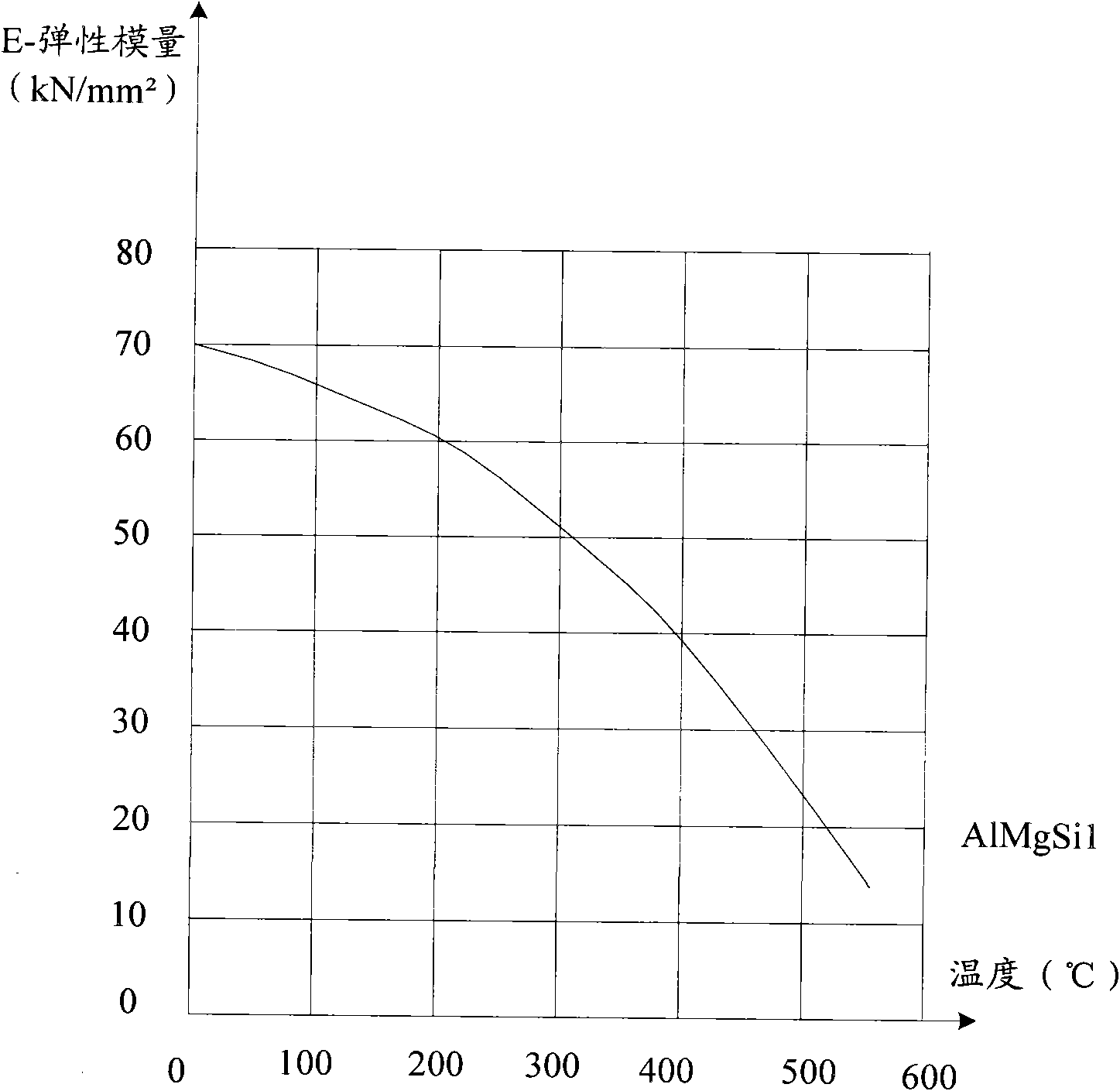

[0019] One of the core ideas of the present invention is: assuming that the temperature of the fire reaches 700°C to 950°C, calculate the thermal load deformation of the weakest link of the static strength of the car body, and verify the loss of car body strength and stiffness caused by the fire. Whether softening, deformation, and collapse affect its evacuation, escape, rescue implementation, and whether it has reliable driving ability within a certain period of time at a safe speed. If the vehicle body is not able to meet the fire protection performance requirements, that is, the driving ability requirements after calculation and verification, add thermally expandable non-metallic fireproof materials in the weakest static strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com