Self-offset correcting conveyor

A conveying device and roller technology, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of wasting manpower and time, prone to deviation, inaccurate accuracy, etc., so as to improve accuracy and efficiency and save manpower time. , the effect of simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

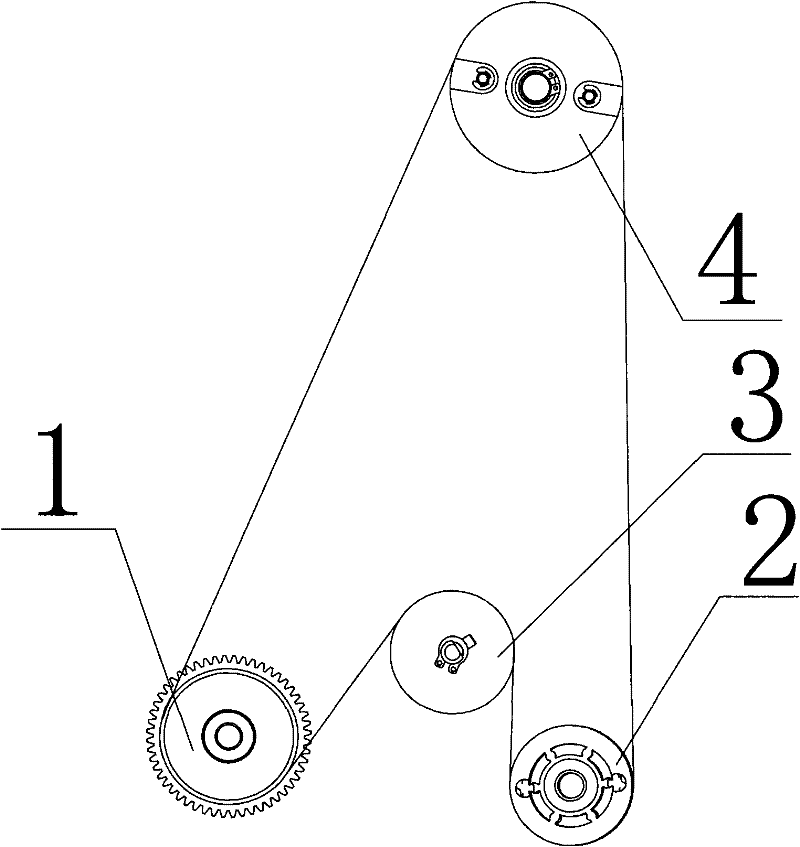

[0029] Embodiment: a kind of self-correction transmission device, such as figure 1 As shown, it includes a power wheel 1 and a working wheel 2. A buffer wheel 3 and a leveling structure 4 are arranged between the power wheel 1 and the working wheel 2. The axis of the buffer wheel 3 is slightly higher than the power wheel 1 and the working wheel. 2, the axis of the leveling structure 4 is higher than the axis of the buffer wheel 3, the power wheel 1 and the working wheel 2 are fixed runners, and the buffer wheel 3 is a dynamic runner.

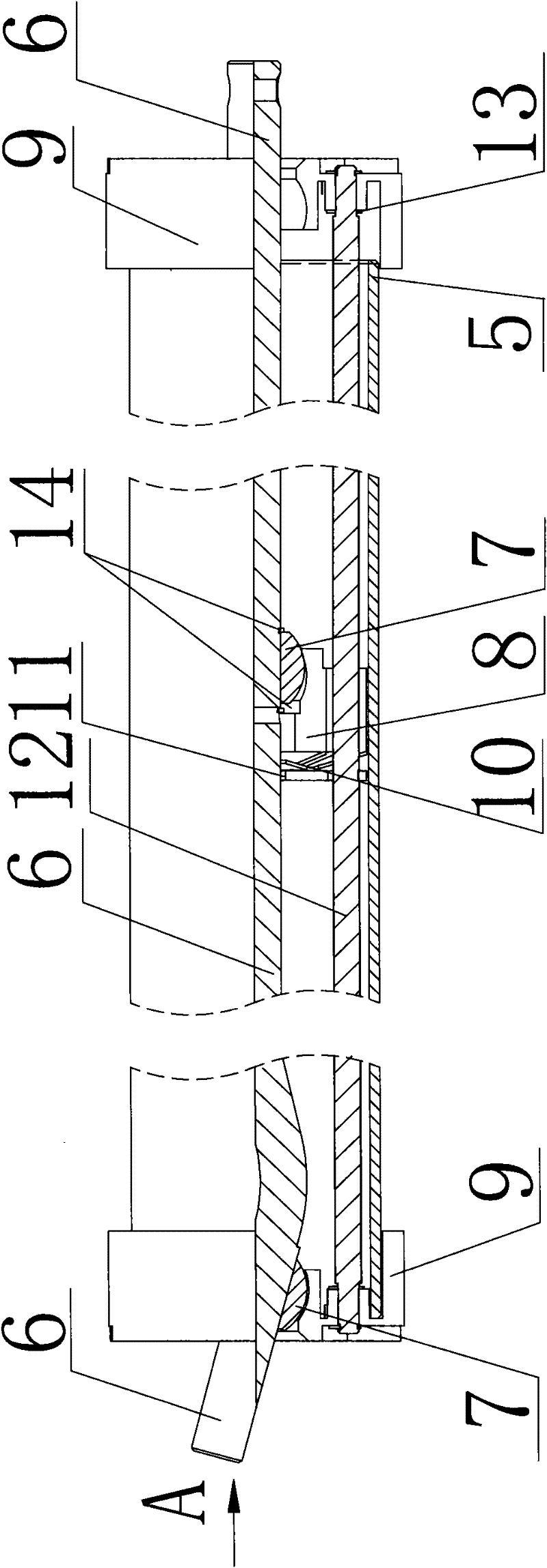

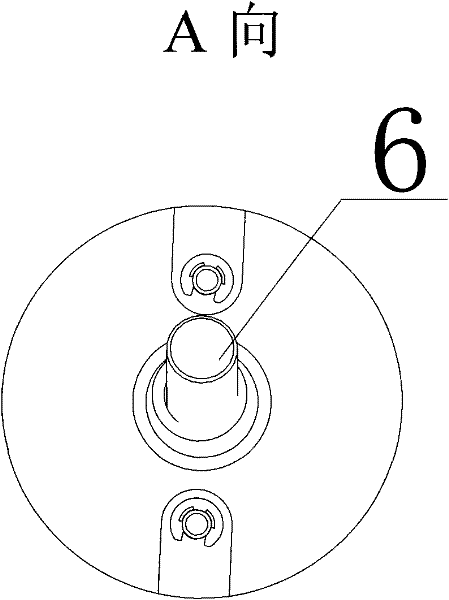

[0030] Such as Figure 2 to Figure 16 As shown, the leveling structure 4 includes a drum 5, a drum main shaft 6 slightly bent at one end, and a waist drum-shaped bush 7 fixedly sleeved outside the central position of the drum shaft 6 axis. 5. In the roller central bushing 8 at the middle position, a side section of the roller central bushing 8 is provided with a limiting structure for locking the relative position of the roller 5 and the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com