Cutting equipment and cutting method for cutting prepregs

A technology of prepreg and cutting equipment, applied in metal processing and other directions, can solve problems such as passivation of cutting tool edges, achieve high cutting dimensional accuracy, eliminate broken fine semi-cured resin and resin glass fiber dust, and improve working environment sanitation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

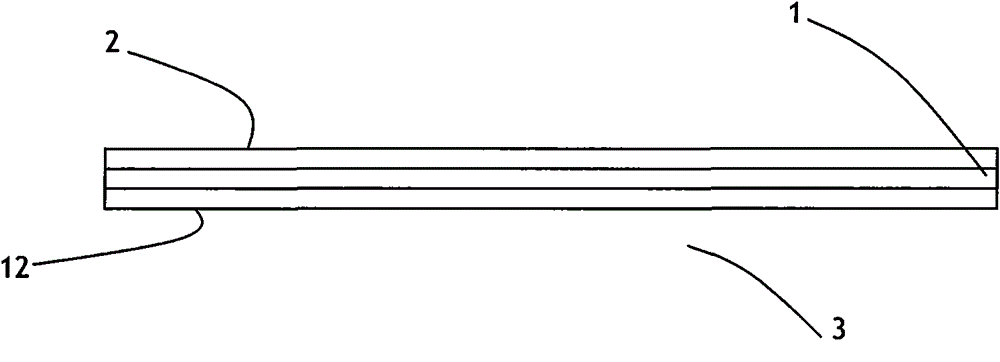

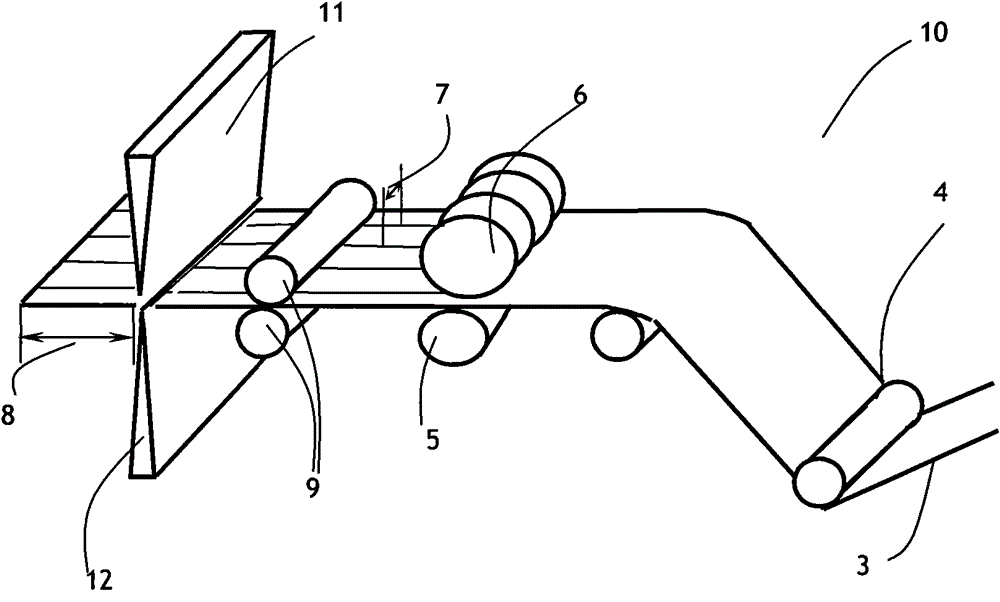

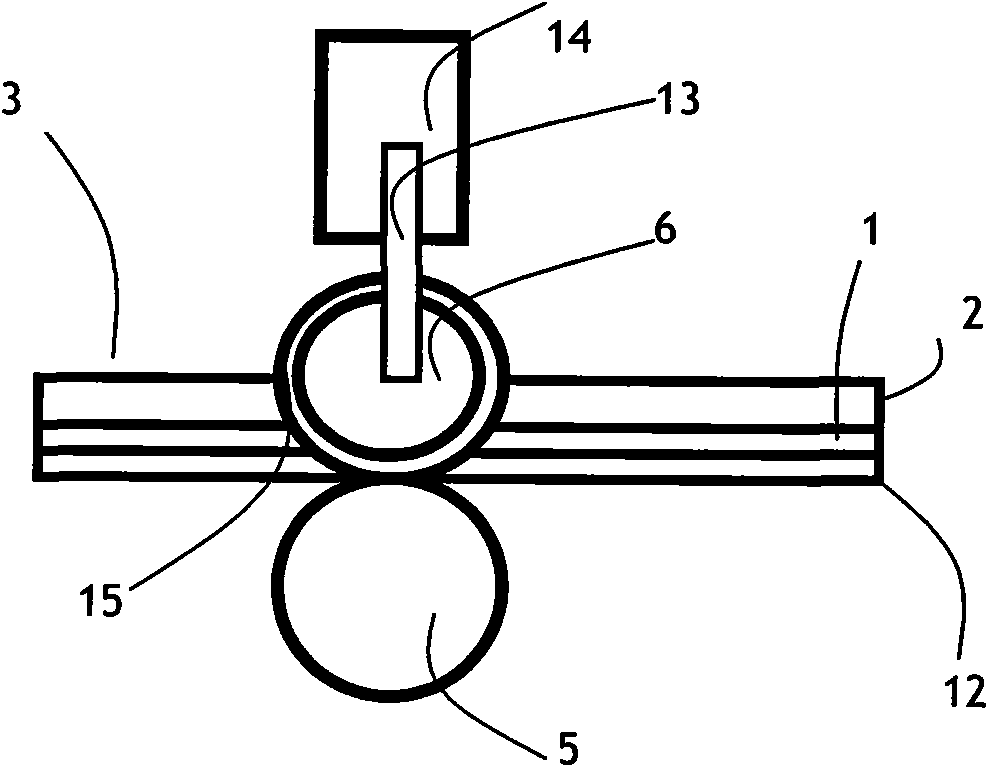

[0042] The method of round knife blade of the present invention is not curled and passivated in the process of cutting and slitting is as follows: Figure 4 As shown in the longitudinal sectional view, in the process of cutting and slitting, always keep the wheel knife blade piercing the epoxy resin 2 and glass cloth base 1 of the prepreg 3 that is in contact with the wheel knife blade 15, only piercing The epoxy resin 12 that does not pierce the semi-curing agent that is in contact with the roller, so that the blade 15 of the wheel cutter does not contact the roller during the cutting and slitting process, thereby ensuring that the blade 15 of the wheel cutter will not curl Passivation, keeping sharp while taking advantage of the brittle nature of the prepreg epoxy, after the prepreg epoxy 2 and glass cloth base 1 are cut and the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com