Automatic flame cutting system with steel casting dead head robot

A flame cutting and robotic technology, applied in gas flame welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of harsh manual operating environment and uneven surface of the incision, reduce labor intensity, increase processing range, and reduce costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

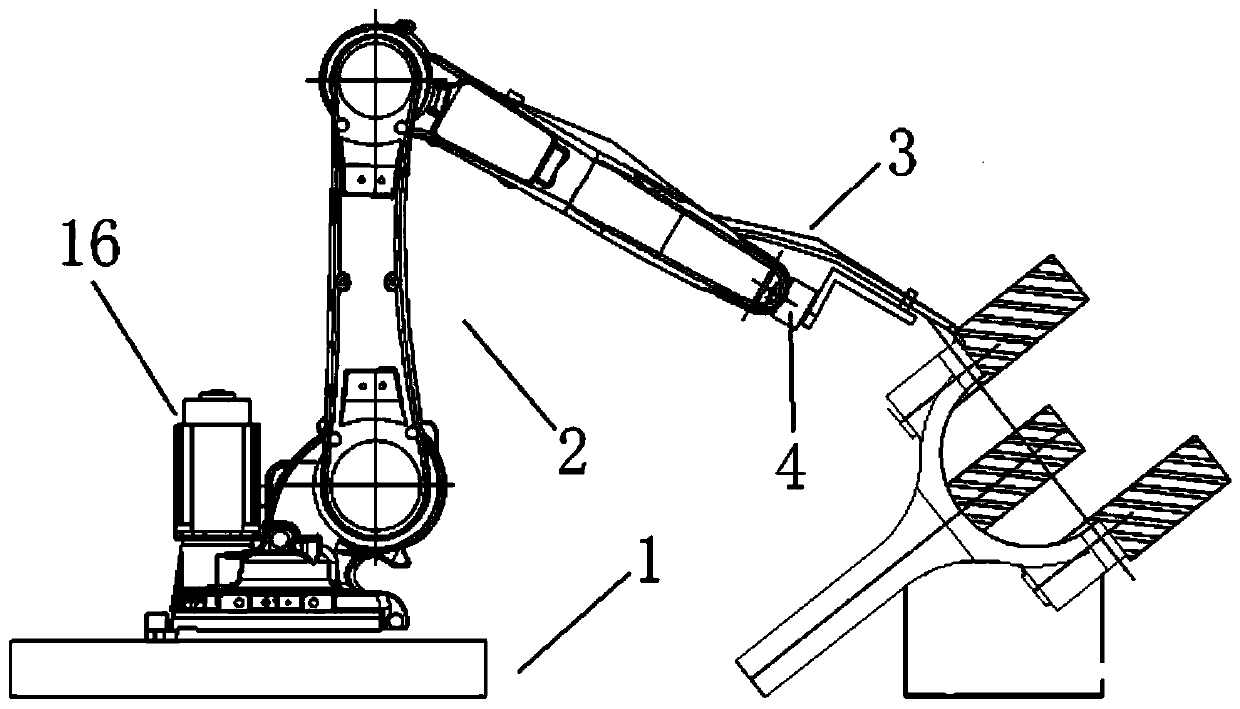

[0027] Such as Figure 1 to Figure 7 As shown, a robot automatic flame cutting system for risers of steel castings includes a vehicle-mounted platform 1, a six-axis robot 2 and a cutting torch 3. The vehicle-mounted platform 1 is fixed with a six-axis robot 2, and the six-axis robot 2 is fixed with a cutting torch. 3;

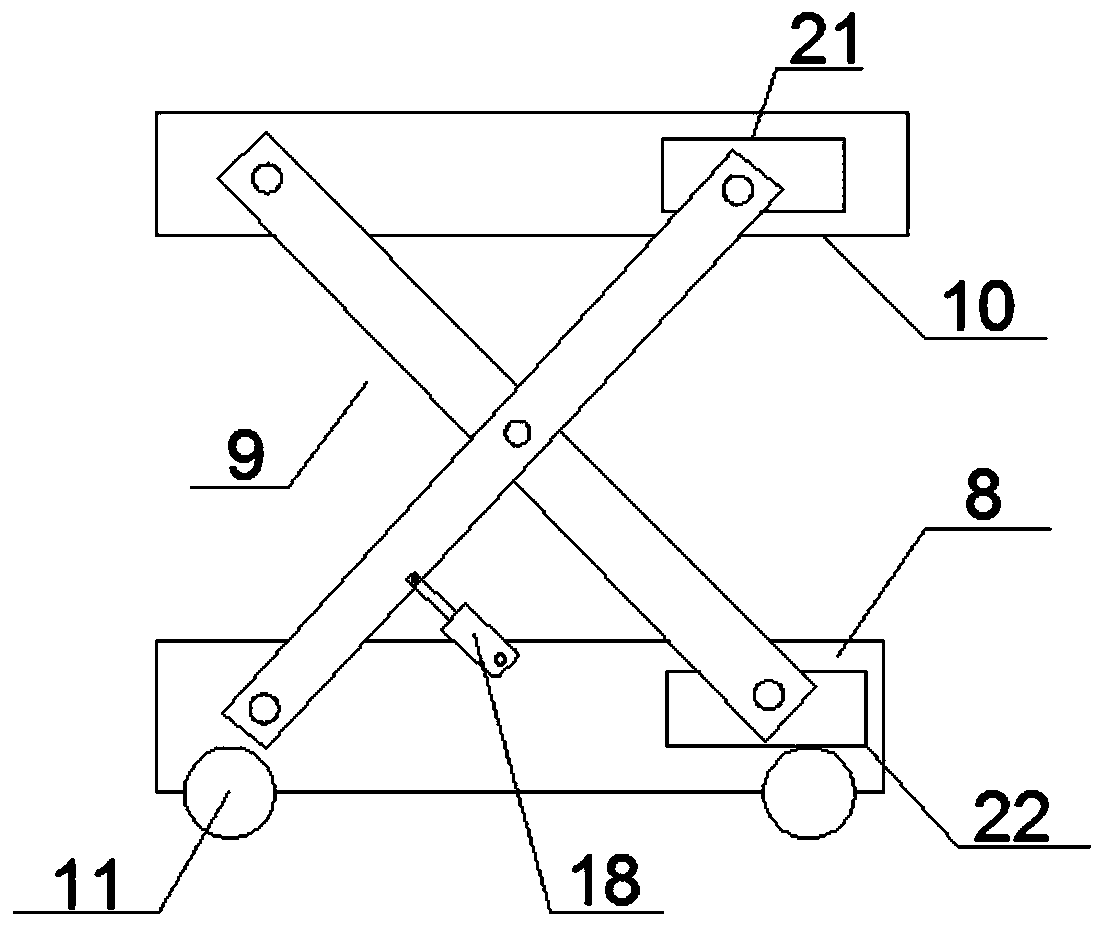

[0028] The vehicle-mounted platform 1 includes a base plate 8, a lifting mechanism 9 and a top plate 10, the lifting mechanism 9 is arranged between the base plate 8 and the top plate 10, the lifting mechanism 9 is used for lifting the top plate 10, and the two ends of the bottom plate 8 are provided with moving wheels 11;

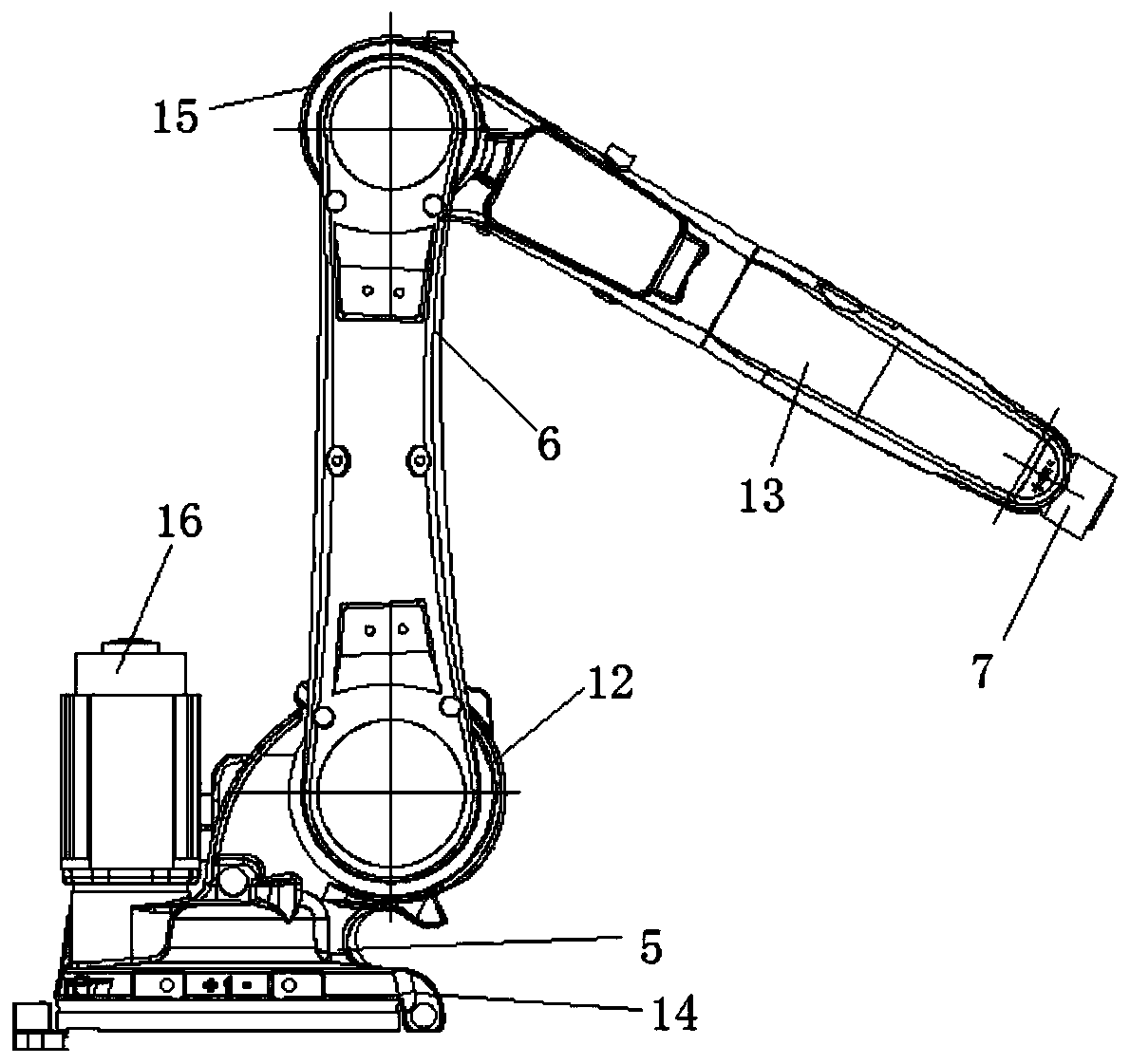

[0029] Such as figure 2 As shown, the six-axis robot 2 includes a fixing device 4, a fixed base 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com