Separate type cable rolling tray

A separate, cable reel technology, applied in the field of take-up reels, can solve the problems of not being very environmentally friendly, waste, and increasing costs, and achieve the effect of saving resources and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

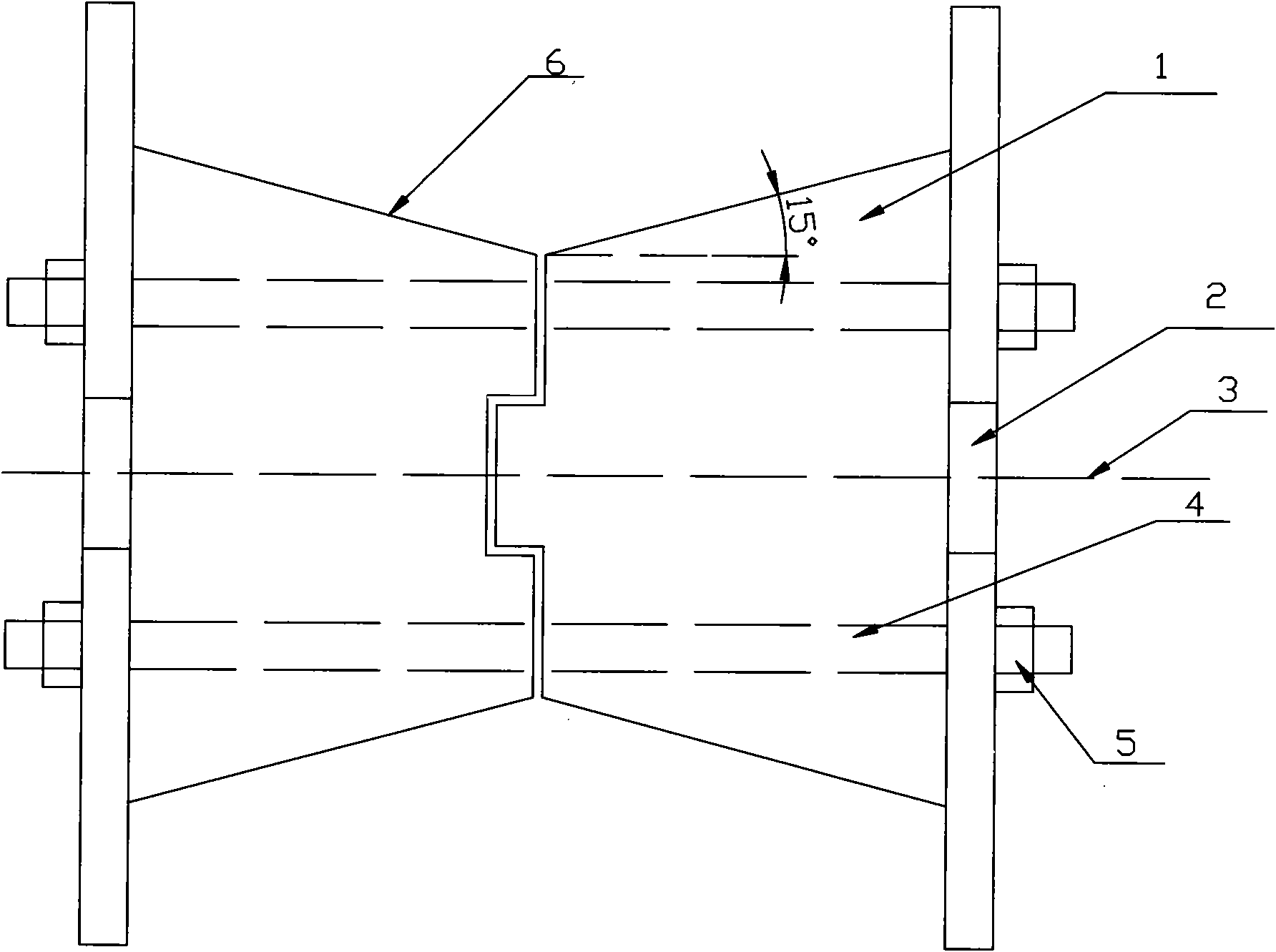

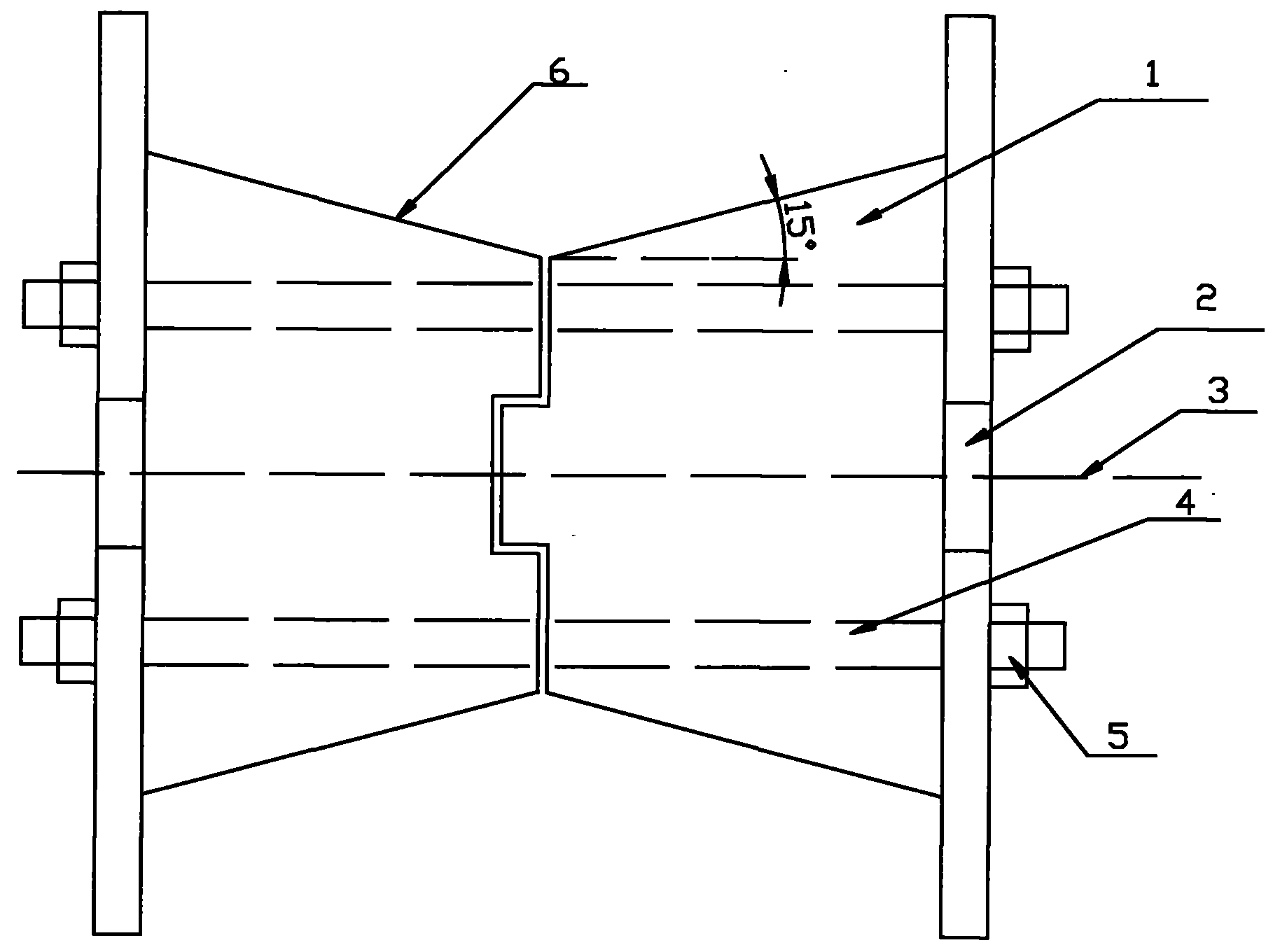

[0013] Such as figure 1 A separate cable take-up reel is shown, which includes a thimble hole 2, and the take-up cable reel is composed of two half-sided plates 1, and the two half-sided plates 1 are connected by a connecting piece; The angle between the take-up surface 6 of the half-sided plate 1 and the axis 3 is 0° to 30°; a further optimization scheme is that the angle between the take-up surface 6 and the axis 3 is 15°; the connection Parts are bolts 4 and nuts 5, and there is at least one pair; a further optimization scheme is that there are four pairs of bolts 4 and nuts 5.

[0014] Use 4 long bolts 4 and nuts 5 to fix the two half-sided plates 1 into a plate and put them on the production line. The thimble hole 2 is used for the thimble on the production line to withstand the plate.

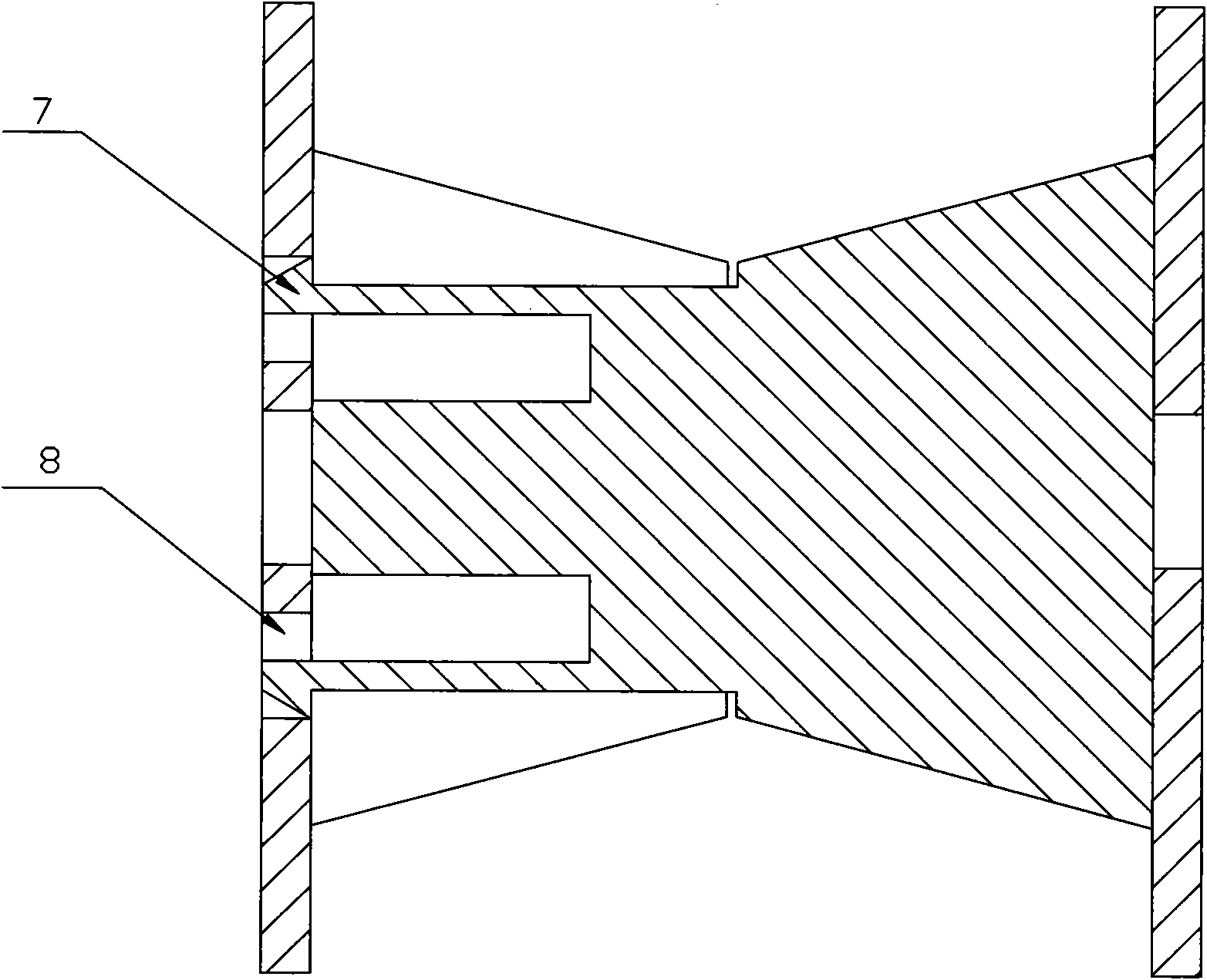

[0015] Such as figure 2 As shown, in another embodiment of the present invention, the connecting member uses a tenon 7 and a slot 8 .

[0016] It is more convenient to use the cable r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com