Novel multistage centrifugal pump

A centrifugal pump and a new type of technology, applied in the field of centrifugal pumps, can solve the problems of easy to produce a hump in the lift curve, increase the outlet width, and reduce the pump efficiency, and achieve the effect of improving the performance range, reducing the leakage and improving the efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

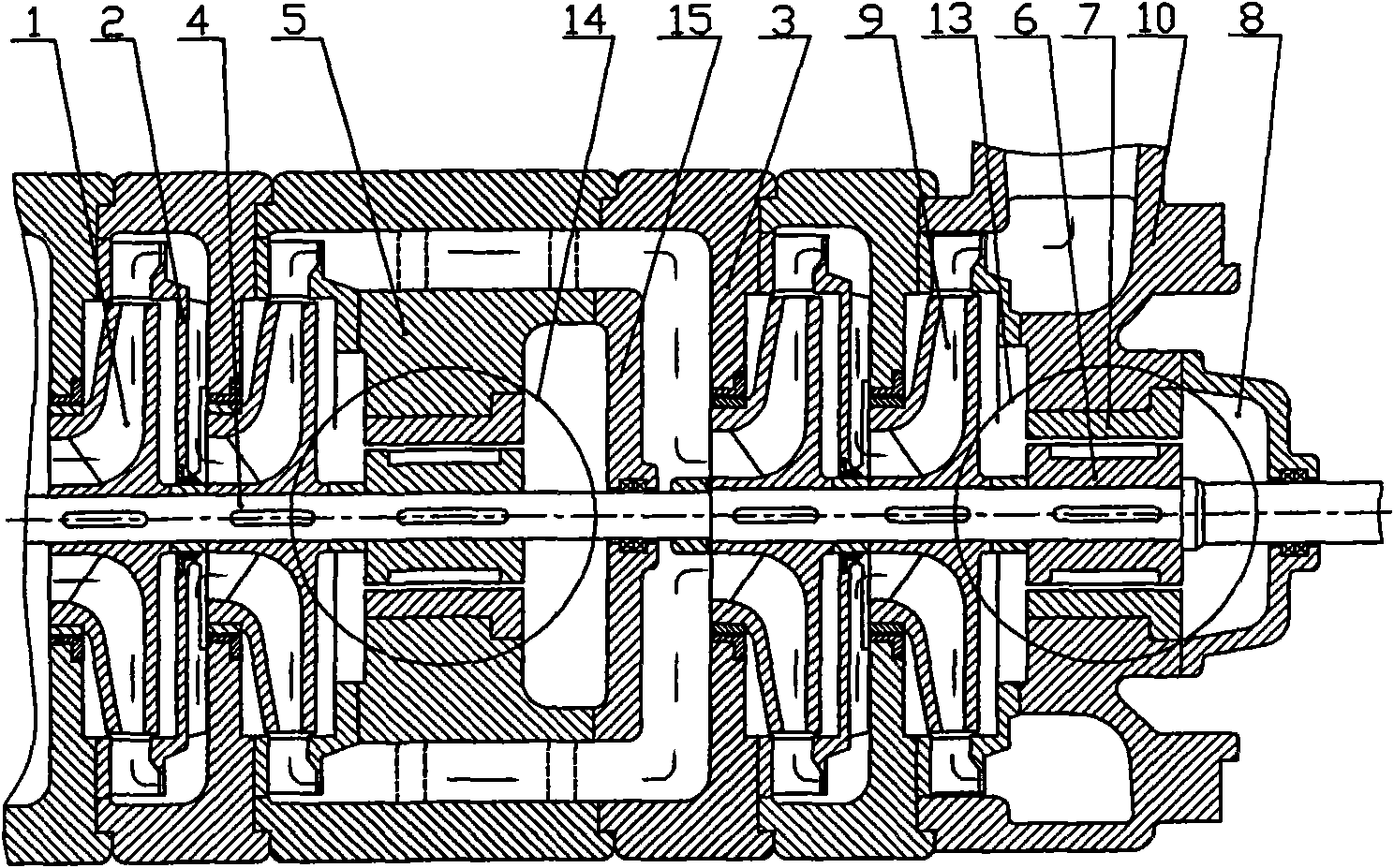

[0017] Example: such as figure 1 , the new multi-stage centrifugal pump includes a pump shaft 4, on which a set of impellers 1 and guide vanes 2 matched thereto are arranged, the flow channel between the impellers 1 is connected by the middle section 3, and the last stage impeller 9 is connected with a water spouting section 10, When the pump is running, the liquid is sucked into the pump from the inlet, and the velocity energy and pressure energy of the liquid are increased by the action of the impeller 1, and then enters the impeller of the next stage through the guide vane 2 and the middle section 3, and finally the liquid is pumped by the final stage The impeller 9 is discharged to the spouting section 10, where most of the speed energy is converted into pressure energy, and then sent out along the discharge pipeline.

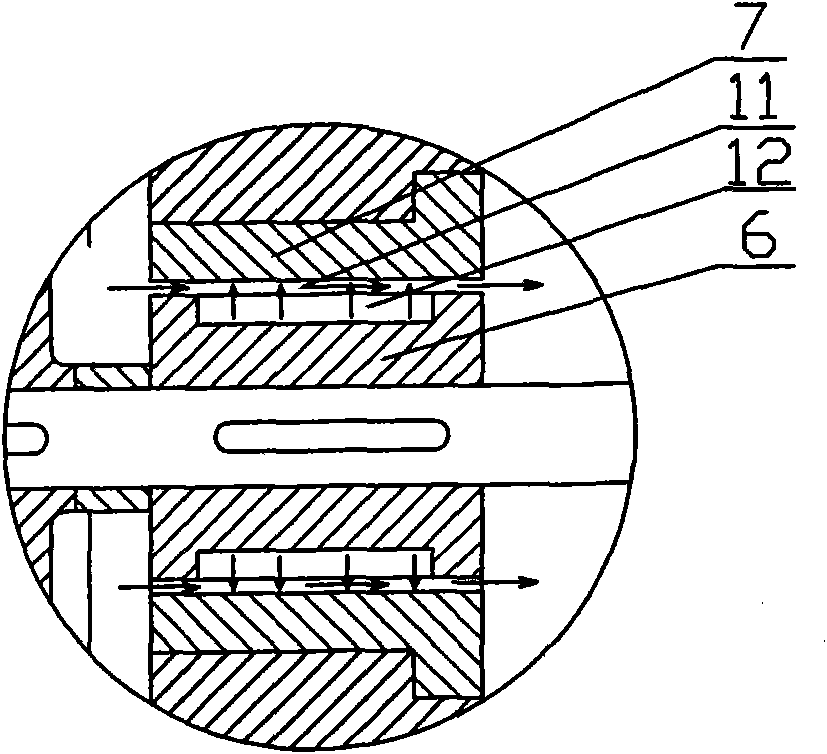

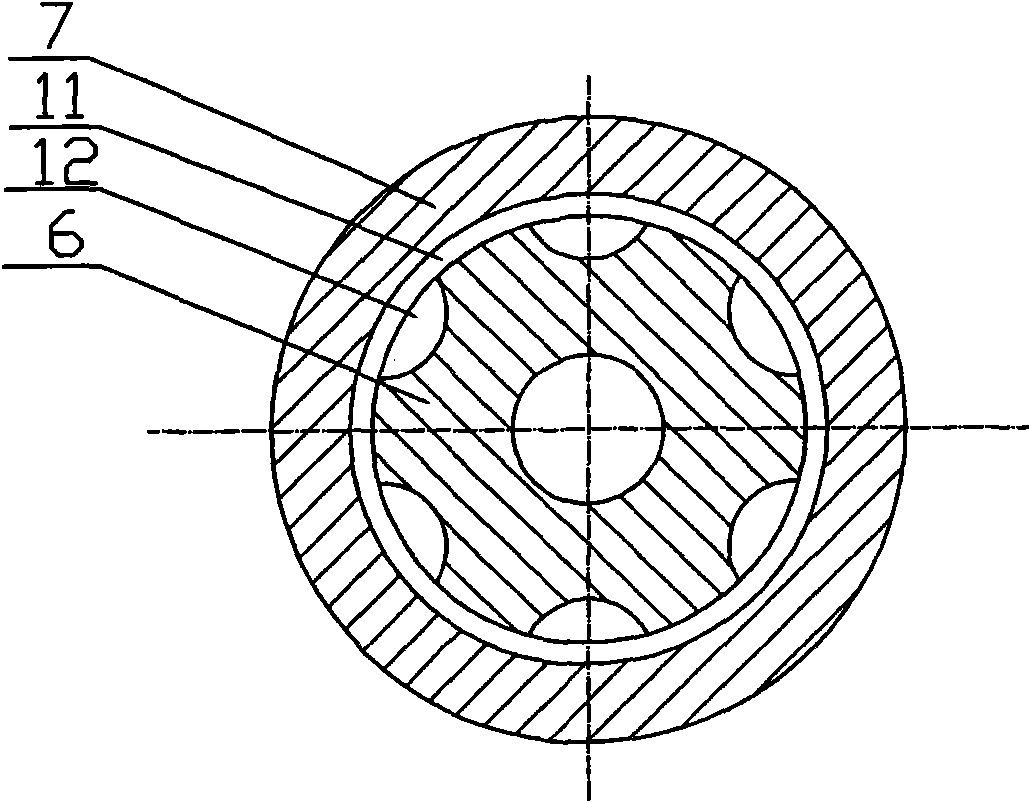

[0018] Wherein the rear side of the final stage impeller 9 is provided with a rear axial force balance device 13, such as figure 2 , 3 , consists of a b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com