Portable calibrating device for pull pressure sensor

A technology of pulling pressure sensor and calibration device, which is applied in the direction of measurement device, force/torque/work measuring instrument calibration/test, measurement of fluid pressure, etc. Inconvenient, bulky weights, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The patent of the present invention will be further described with specific embodiments below in conjunction with the accompanying drawings.

[0023] As shown in the attached picture:

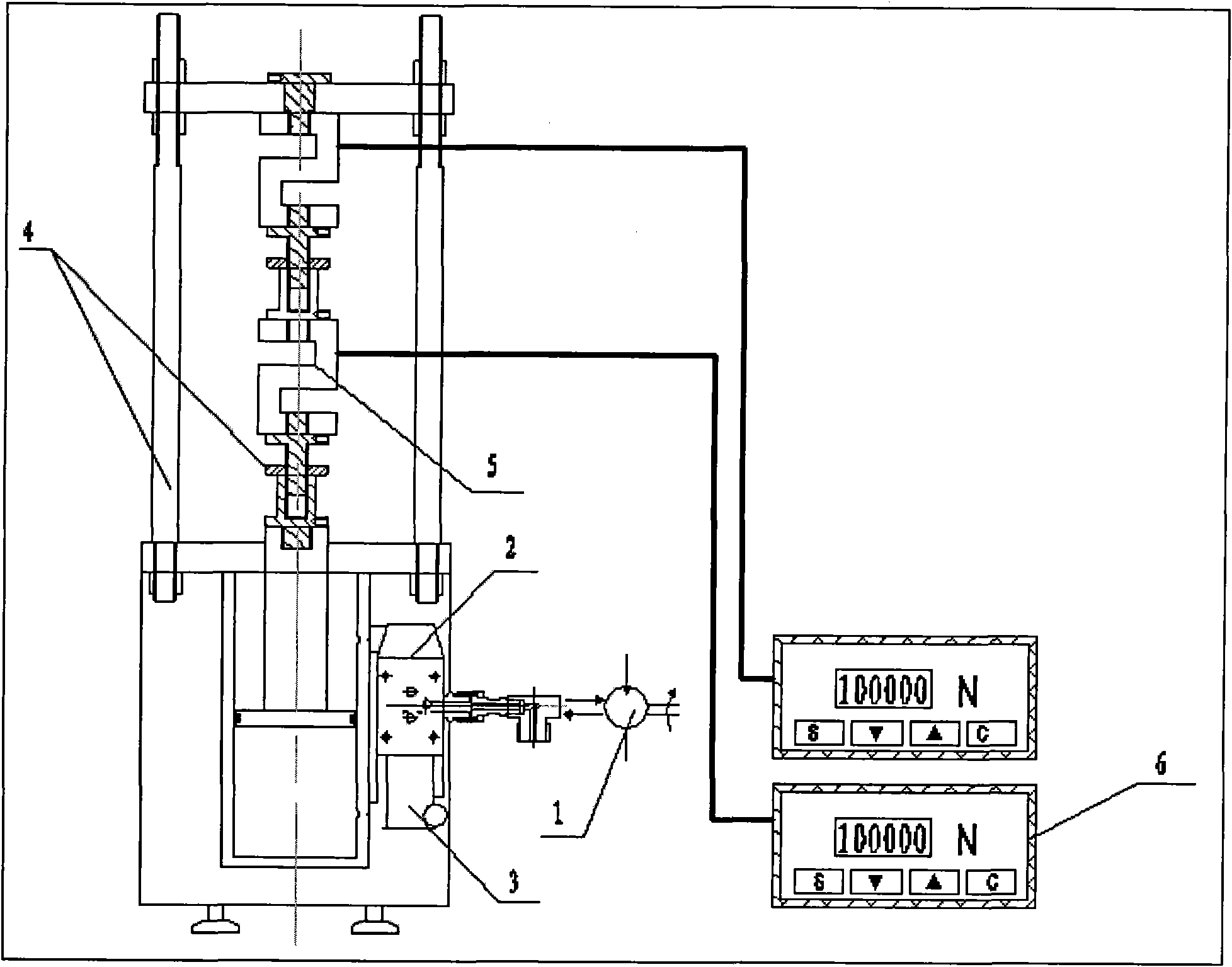

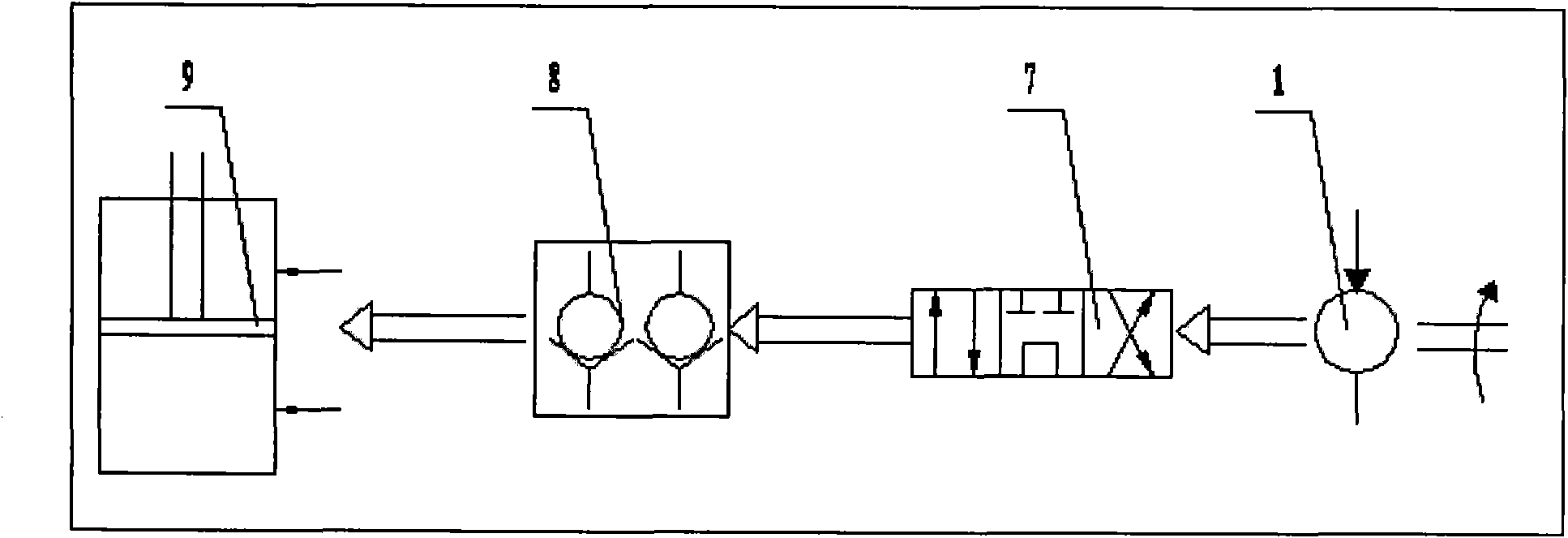

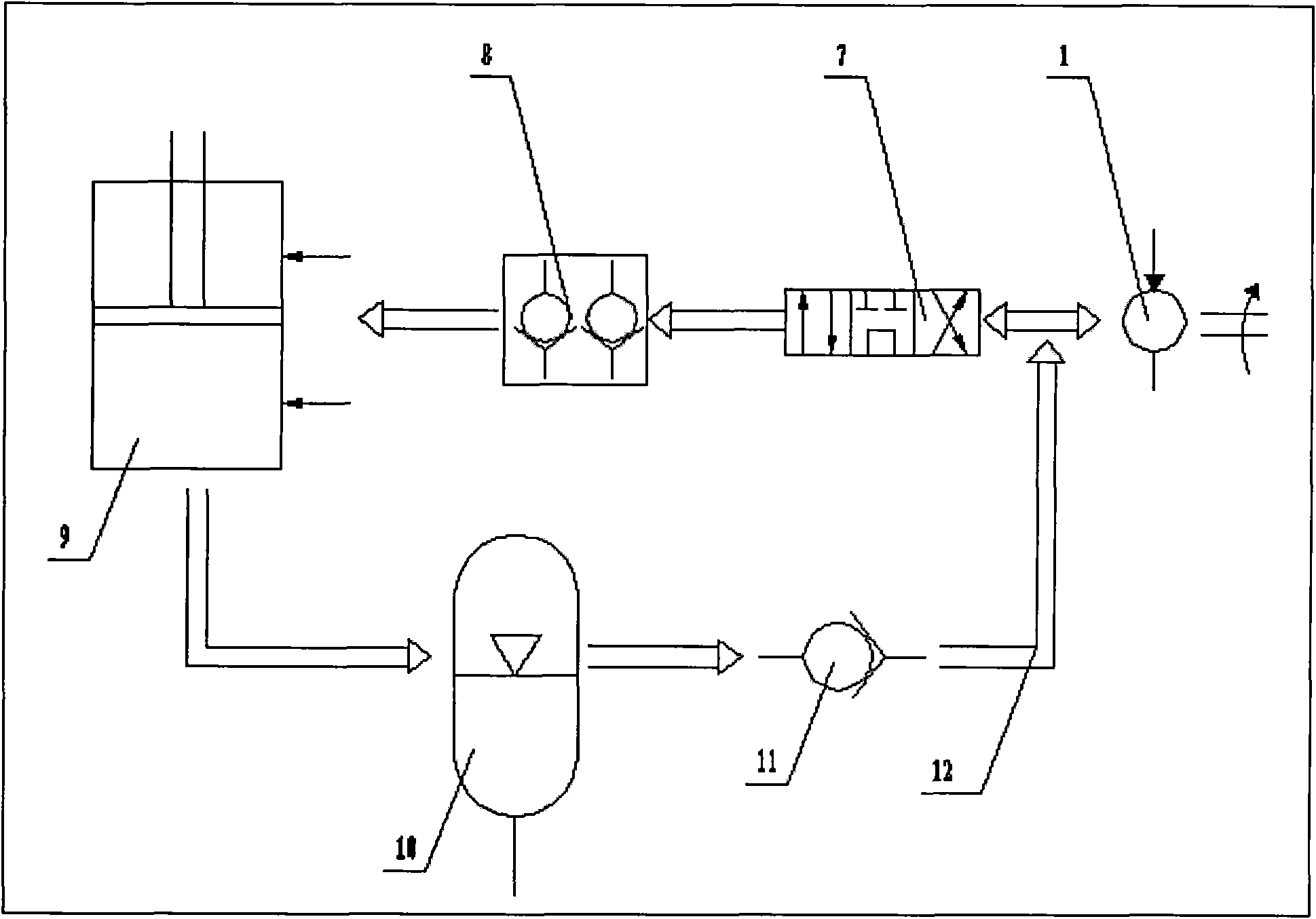

[0024] The portable pull pressure sensor calibration device of the present invention is composed of six parts: a one-way quantitative hydraulic pump 1, a two-way hydraulic control module 2, a one-way oil return device 3, a special calibration fixture 4, a standard force sensor 5 and a standard force value display 6; The two-way hydraulic control module 2 is composed of an oil circuit switching valve 7, a two-way hydraulic lock 8 and an oil cylinder 9; the one-way oil return device 3 is composed of an oil reservoir 10, a one-way valve 11 and an oil return conduit 12; The calibration special fixture 4 is composed of a housing 13, a level adjuster 14, a weighing bracket 15, a lower base plate 16, an upper base plate 17, a lower base plate clamp 18, an upper base plate clamp 19, a level 20 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com