Lens module

A technology of lens modules and optical components, applied in the direction of instruments, electrical components, circuits, etc., can solve the problems of affecting imaging quality, uneven force on optical components, affecting verticality, etc., and achieve the effect of improving imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

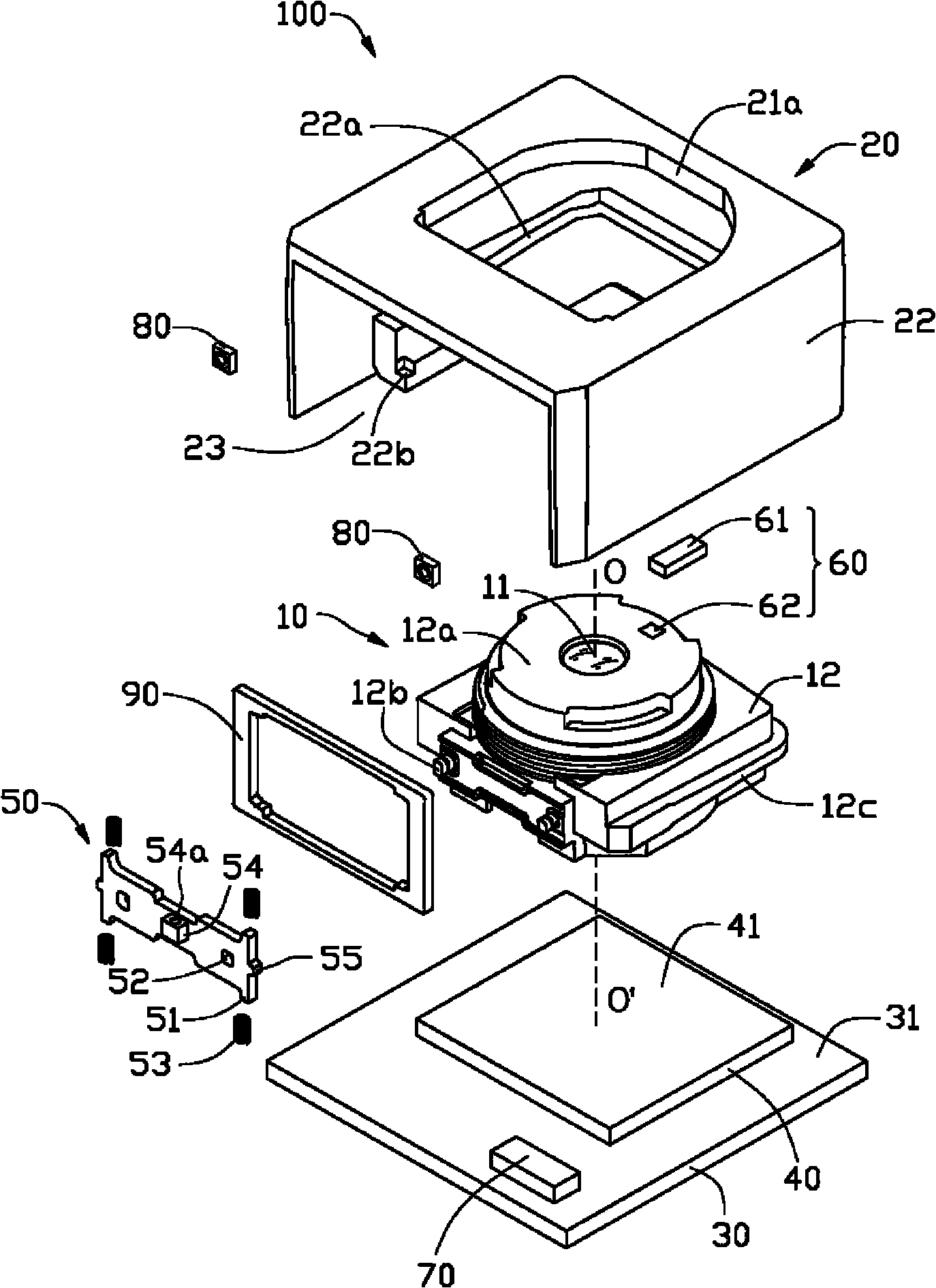

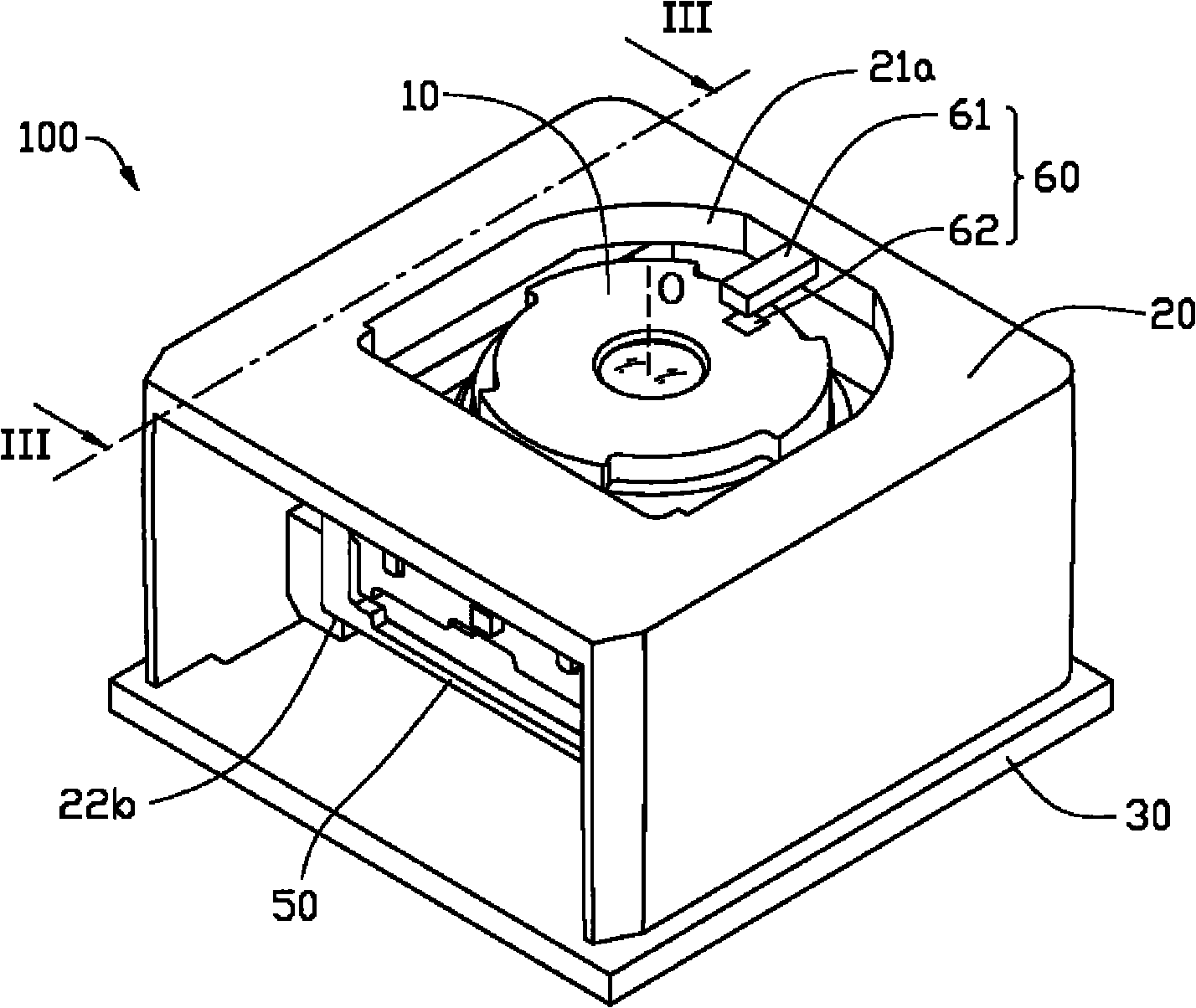

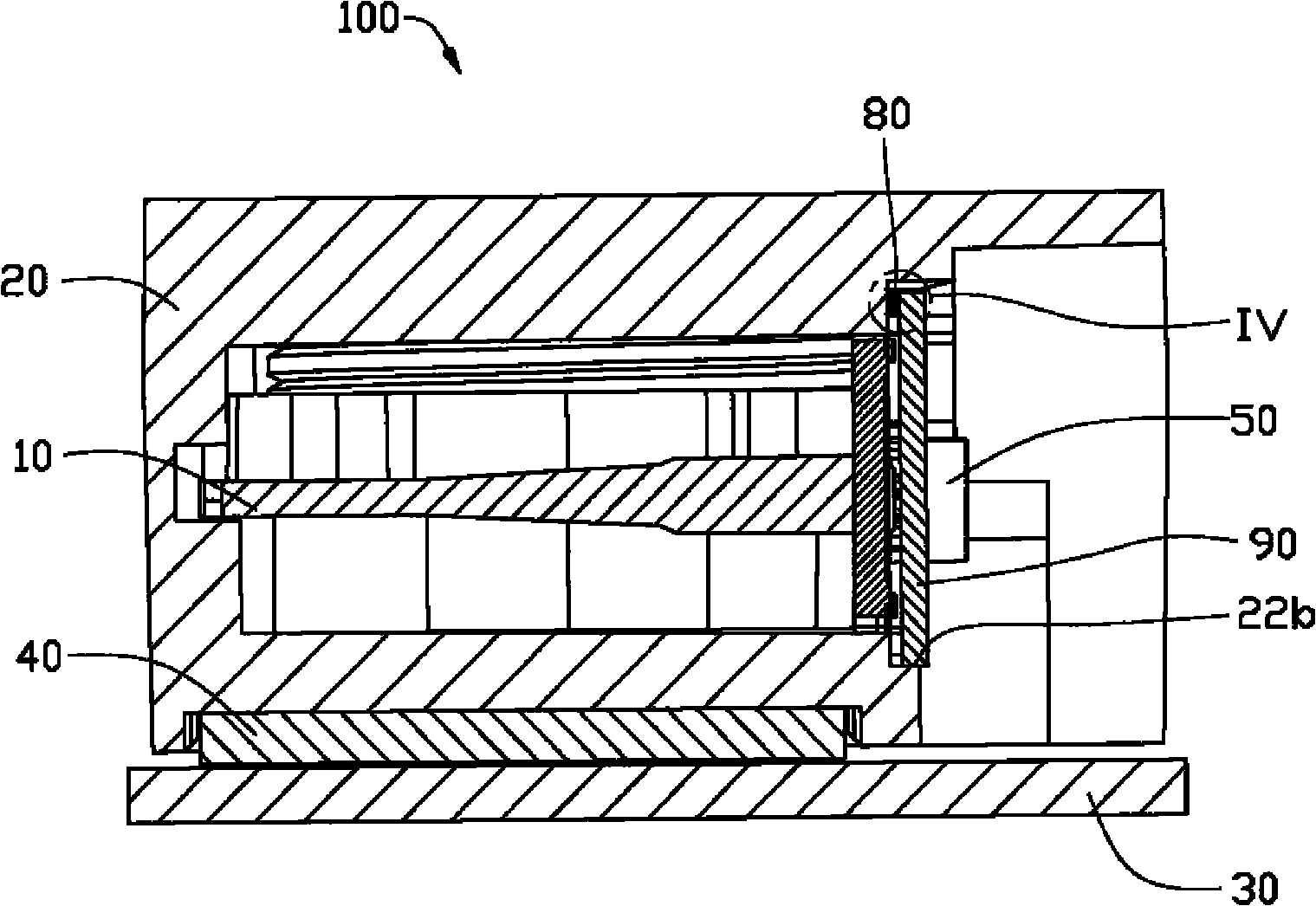

[0017] see figure 1 and figure 2 . The lens module 100 provided by the first embodiment of the present invention. In this embodiment, the lens module 100 is a zoom lens. The lens module 100 includes an optical component 10 , an accommodating case 20 , a circuit board 30 , an image sensor 40 , a connection board 50 , an optical inclination sensor component 60 , a controller 70 , an adjustment component 80 and a limit frame 90 .

[0018] The circuit board 30 includes a top surface 31 . The image sensor 40 has a sensing surface 41 . The image sensor 40 is fixed on the top surface 31 of the circuit board 30 . The accommodating shell 20 is substantially a cube, and the accommodating shell 20 includes a top plate 21 , a side wall 22 and an insertion opening 23 . The top plate 21 is processed with a light hole 21a, and the side wall 22 is processed with a slide groove 22a and a stepped structure 22b. The receiving case 20 is fixed on the top surface 31 of the circuit board 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com