Copper wire cleaning device

A cleaning device and copper wire technology, applied in metal extrusion cleaning equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of continuous cleaning of copper wires, affecting the quality of copper wire products, etc., and achieve a simple and practical structure and low cost Low, continuous cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

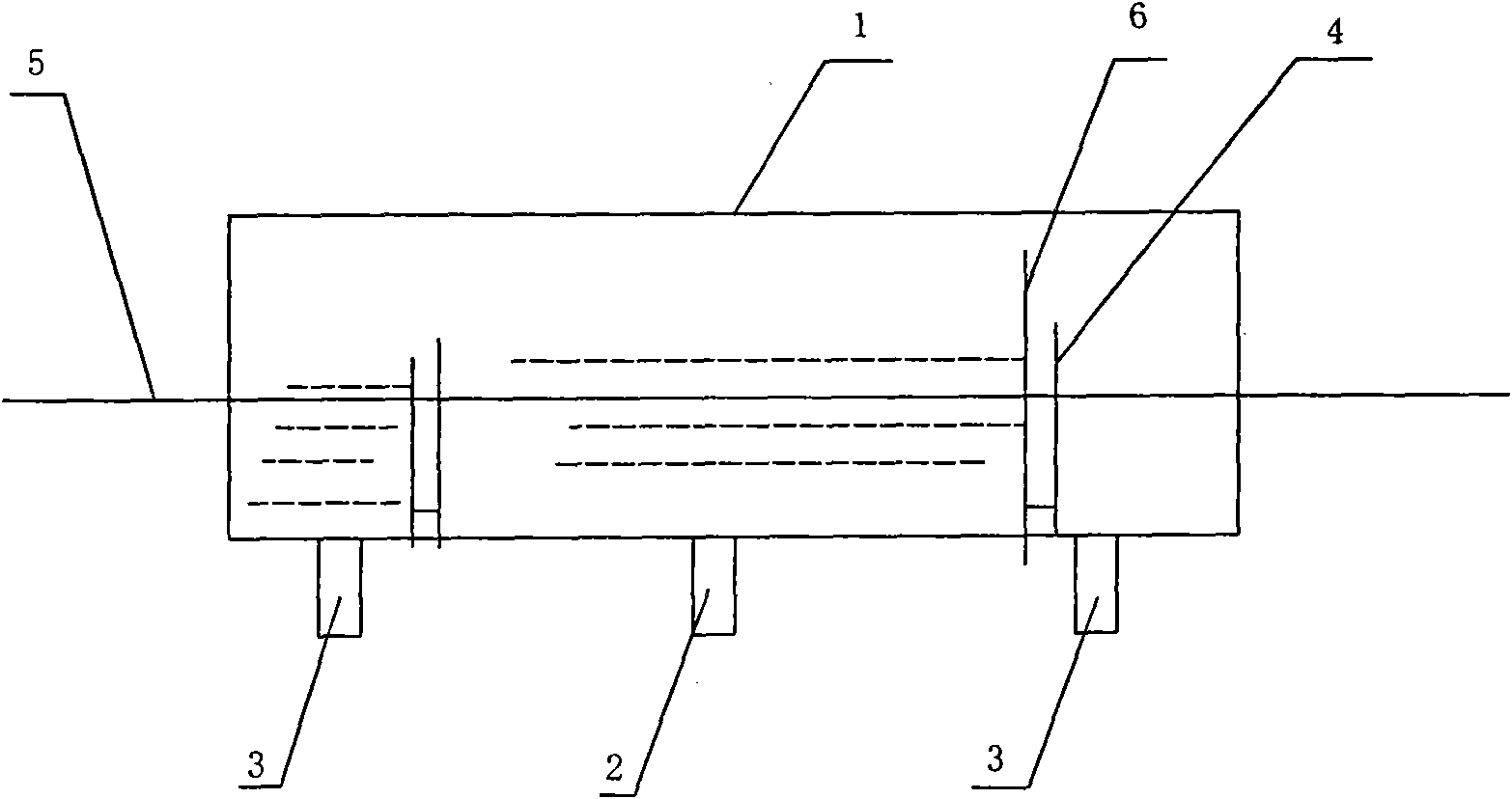

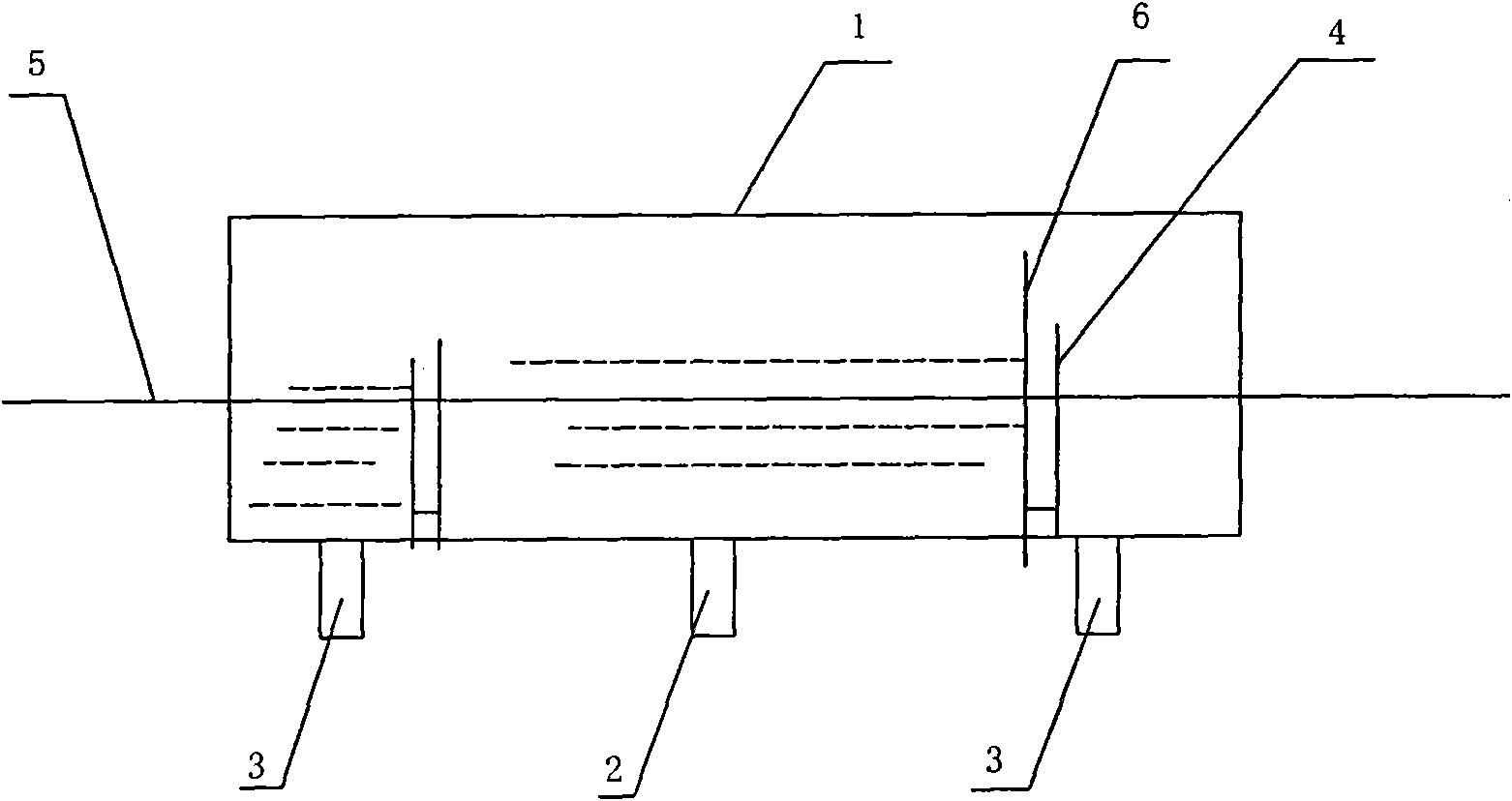

[0010] Such as figure 1 As shown, the present invention mainly includes a water tank 1, and the water tank 1 is provided with a water inlet pipe 2 and a water outlet pipe 3 for feeding continuous flowing water into the water tank 1. A felt pressing plate 4 is arranged in the water tank 1, and felt is pressed under the felt pressing plate 4, and copper wire 5 passes through the felt under the felt pressing plate 4. In addition, a partition 6 is also provided in the water tank 1 to divide the water in the water tank 1 to achieve the effect of enhanced cleaning. The copper wire 5 of the present invention passes through the water tank 1 continuously, and after arriving in the water tank 1, through the action of the felt under the water flow and the felt pressing plate 4, the dirt on the copper wire 5 is cleaned.

[0011] Other unexplained parts involved in the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com