Coreless brushed DC motor and carbon brush-terminal component thereof

A technology of brushed DC motors and terminal components, which is applied in the direction of electric components, electrical components, circuits, etc., can solve the problems of motors that cannot be repaired, motors that cannot work, and structural instability, etc., to achieve improved conduction effects, cost savings, and improved The effect of appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

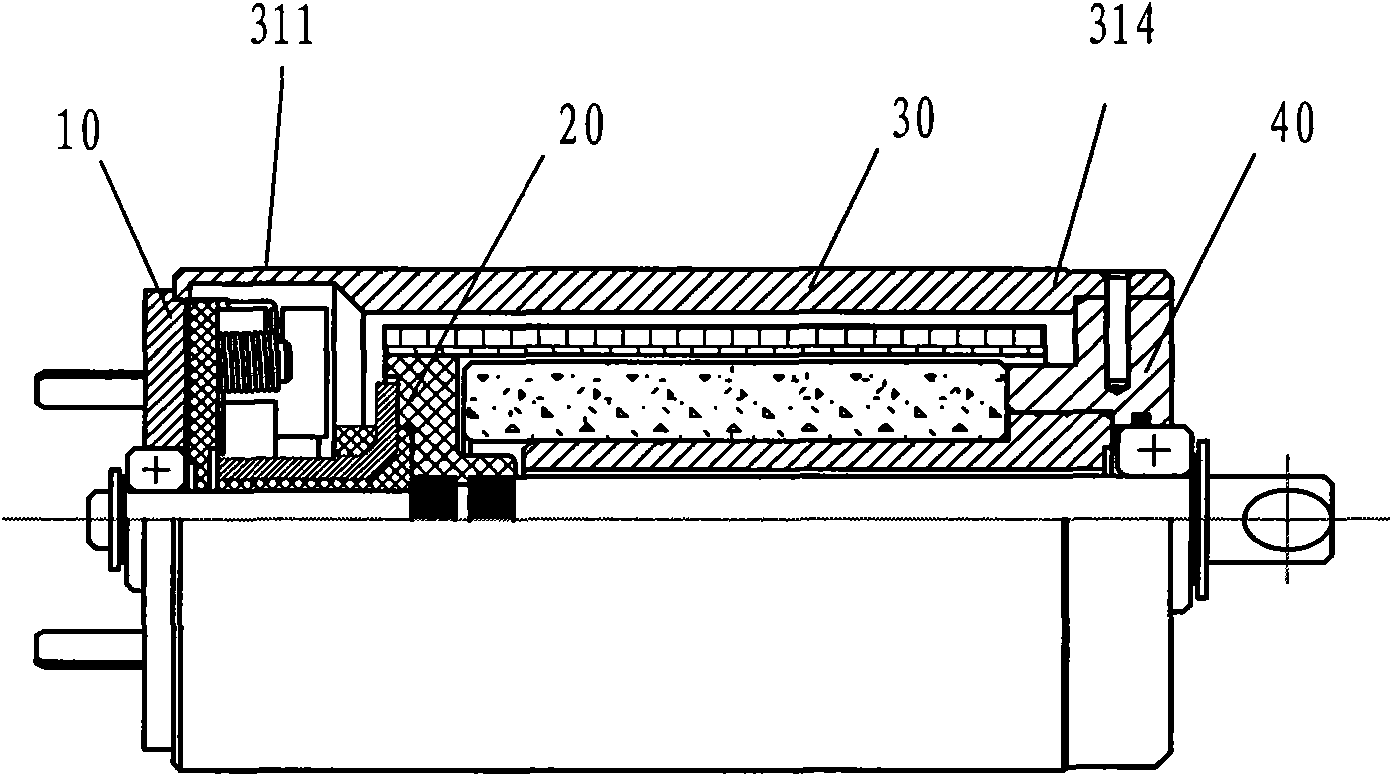

[0042] Such as figure 1 As shown, the hollow cup brushed DC motor of the present invention includes a rear end cover set 10 , a rotor assembly 20 and a stator assembly 30 .

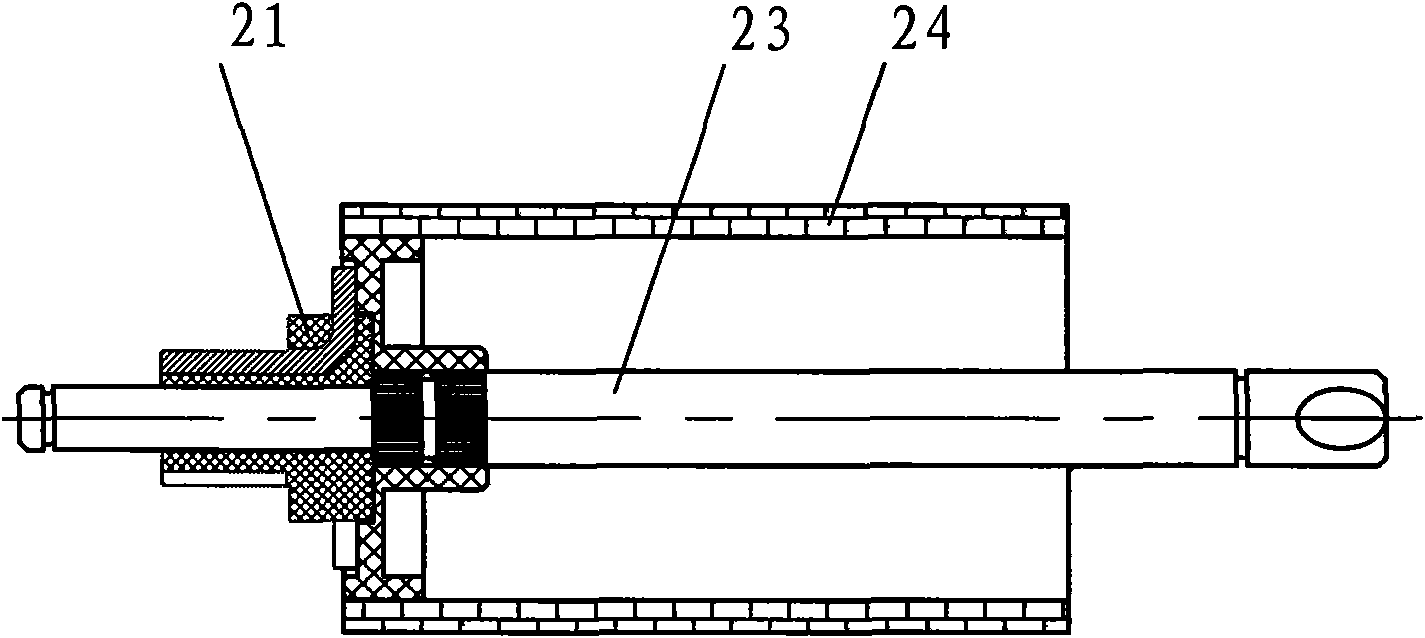

[0043] Among them, such as figure 2 As shown, the rotor assembly 20 includes a rotating shaft 23 , a commutator 21 fixed at one end of the rotating shaft, and a winding cup 24 connected with the commutator and arranged coaxially with the rotating shaft.

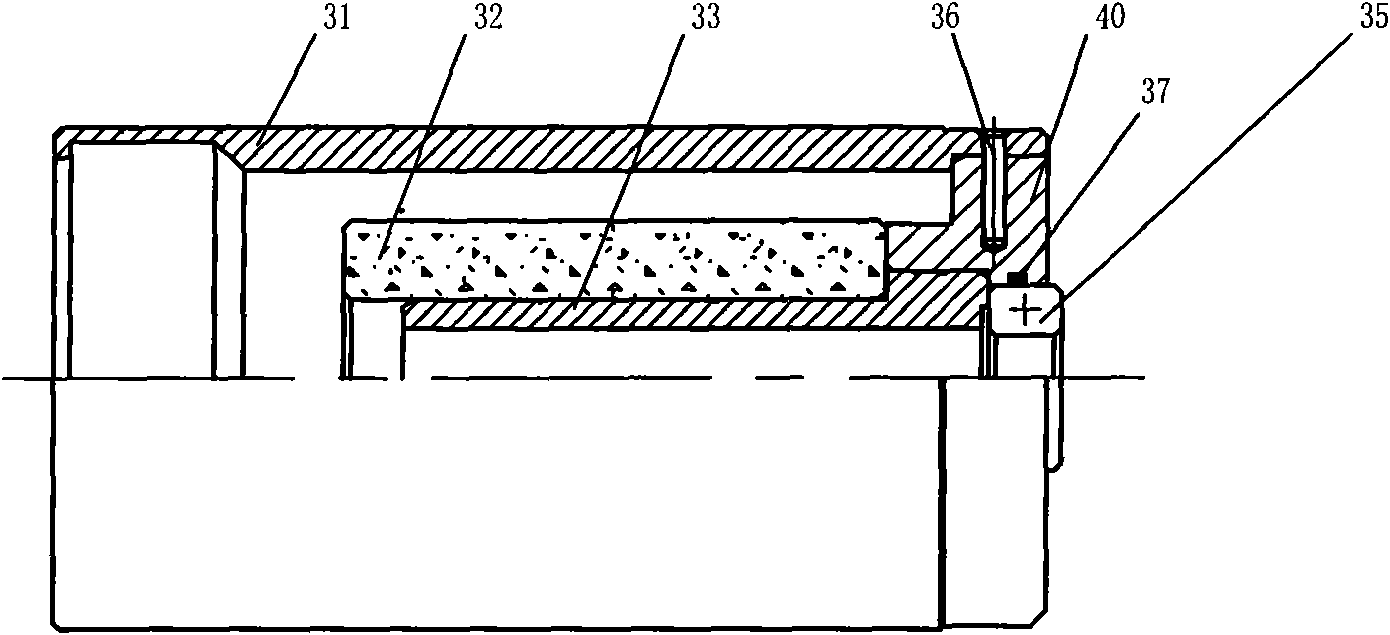

[0044] Such as image 3As shown, the stator assembly 30 includes a cylindrical casing 31 arranged coaxially with the rotating shaft, a magnetic steel 32 , a bearing sleeve 33 and a front cover 40 mounted on the front end 314 of the casing. A bearing 35 is also installed on the front end cover 40 and a vibration damping ring 37 is provided. When assembling the stator assembly, the magnetic steel 32 and the bearing sleeve 33 are installed on the front end cover first, then the front end cover 40 and the casing 31 are interference-fitted, and the casing...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap