Metal shell and electric connector using same

A metal shell and electrical connector technology, applied in the direction of connection, connection component installation, connection device components, etc., can solve the problems of wasteful production cost and reduction of metal plates, and achieve the effect of rational design and reduction of manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

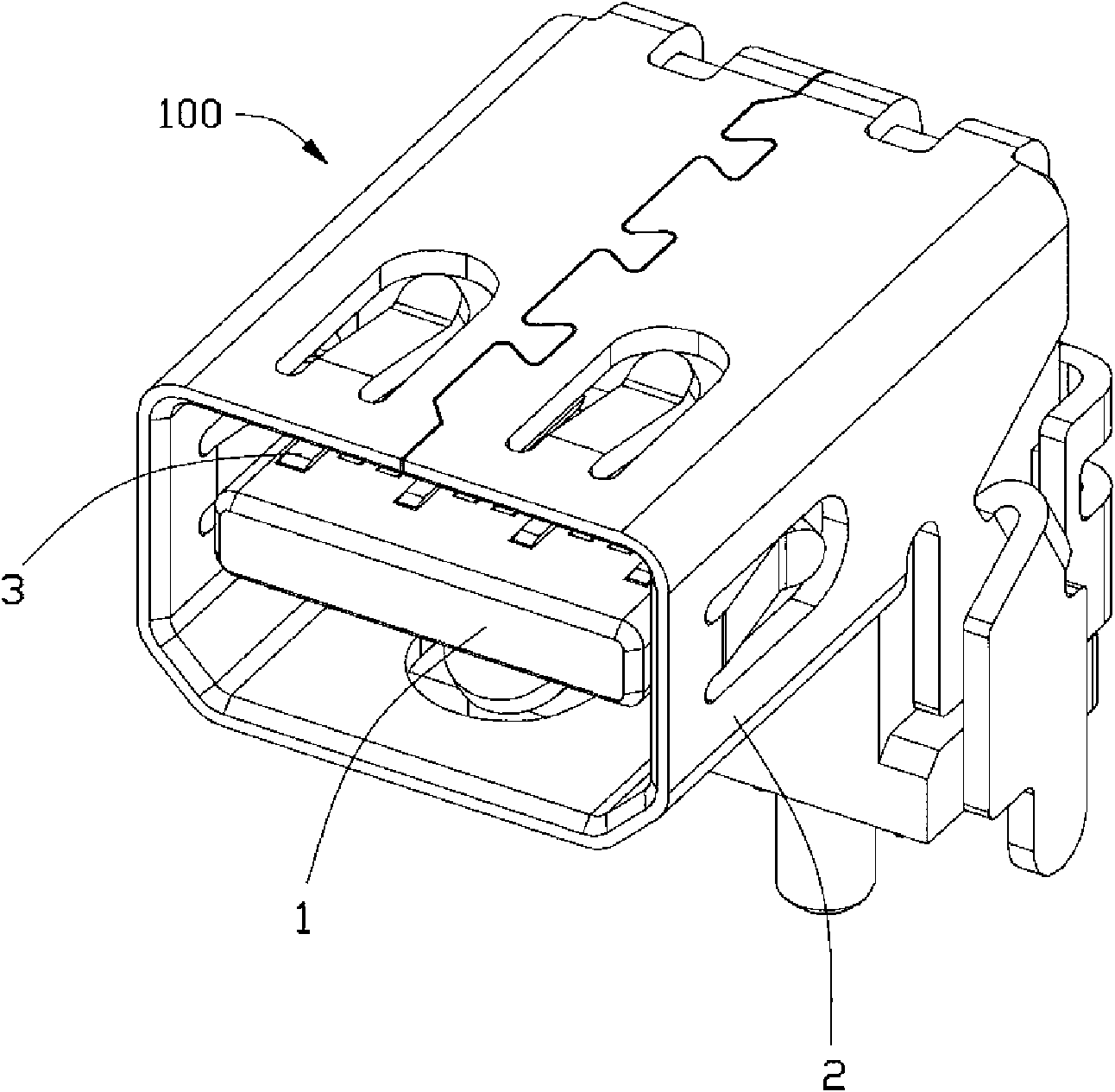

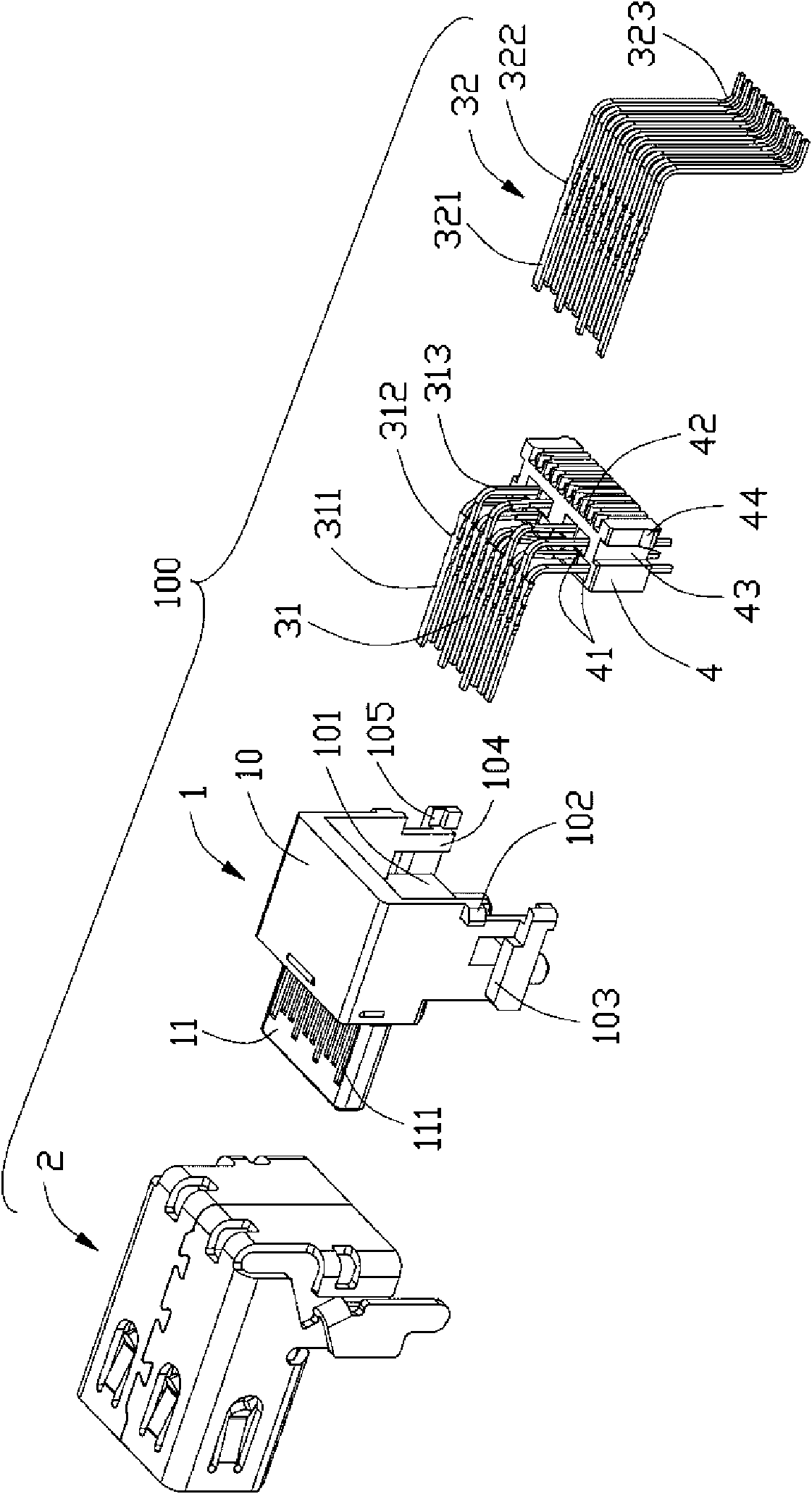

[0014] Such as figure 1 As shown, the electrical connector 100 of the present invention includes an insulating body 1 , a terminal group 3 fixed in the insulating body 1 , and a metal shell 2 covering the insulating body.

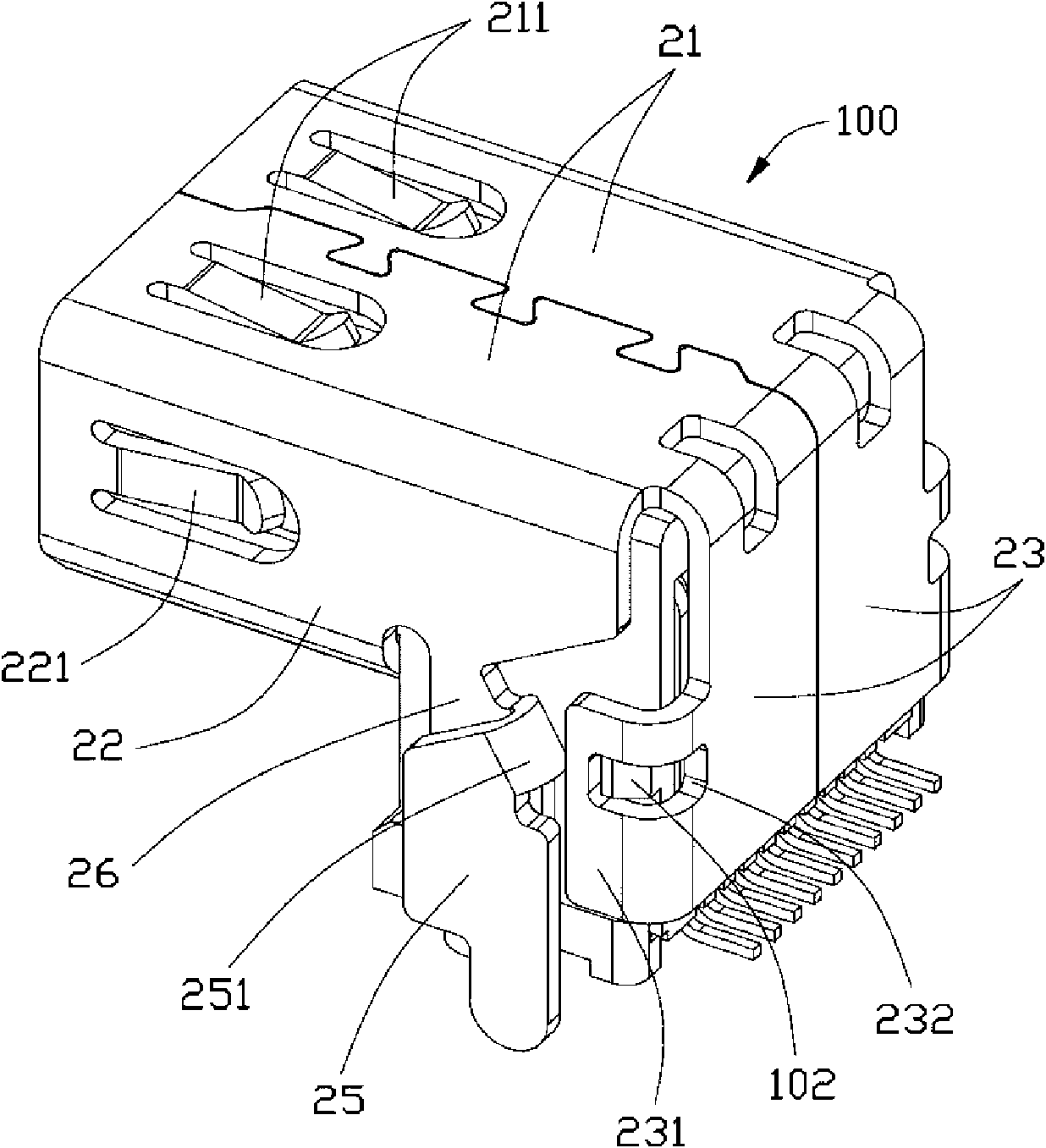

[0015] Such as figure 2 As shown, the insulating body 1 includes a rectangular body portion 10 and a tongue portion 11 vertically extending forward from the body portion 10 . The upper and lower surfaces of the tongue portion 11 are respectively provided with a plurality of terminal slots 111 at intervals, and the terminal slots pass through the body portion 10 of the insulating body backward to facilitate the insertion of the terminal group 3 into the terminal slots 111 from back to front. The rear part of the main body 10 is depressed inwardly to form a receiving cavity 101, and a vertical rib 104 and a protrusion 105 located at the rear end of the rib 104 are respectively provided on both sides of the receiving cavity, and the upper part of the protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com