Metal hydride hydrogen-storing device and its preparation method

A hydrogen storage and hydride technology, which is applied in mechanical equipment, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve the problems of complex processing technology of honeycomb structure, reducing the specific capacity of hydrogen storage, and inconvenient use. , to achieve the effect of ensuring rapid hydrogen absorption and desorption performance, increasing volume specific capacity, and increasing weight specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

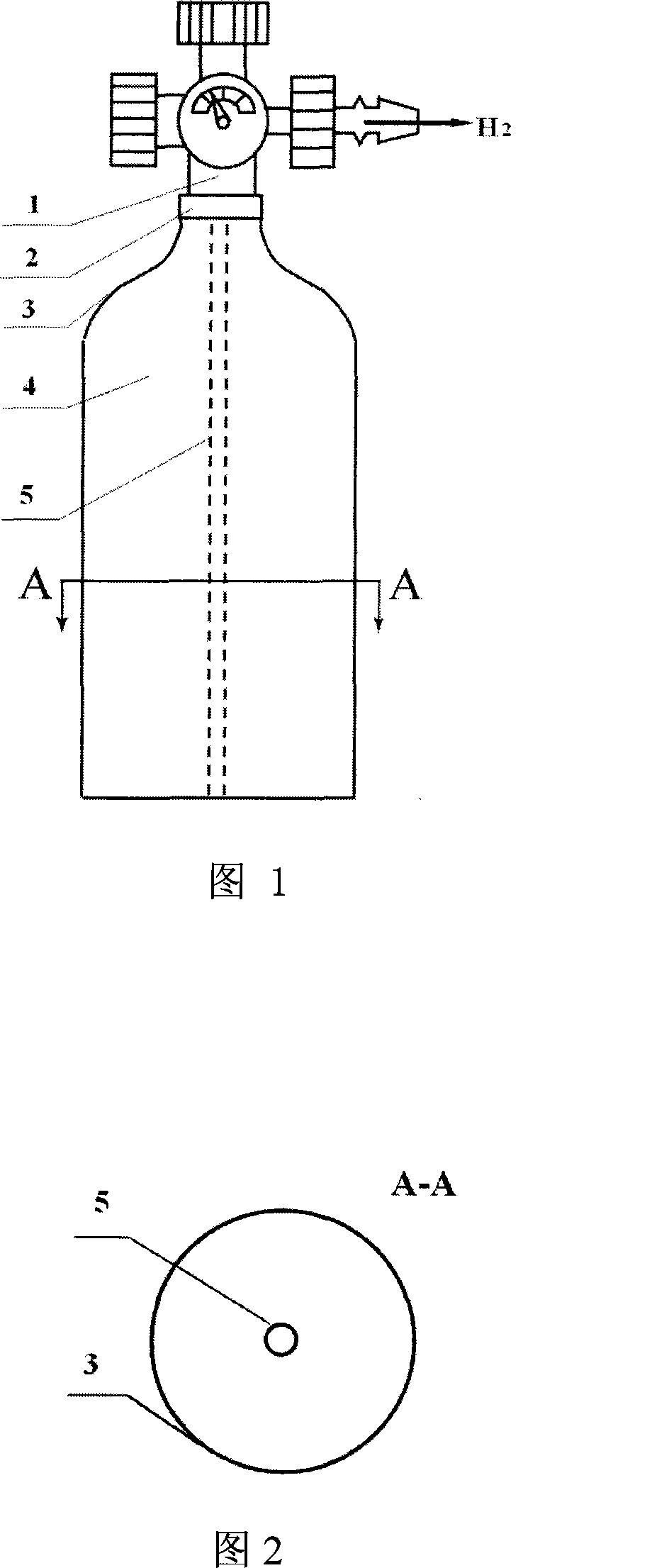

[0017] Metal hydride hydrogen storage device, its internal structure and shape are: stainless steel cylinder, outer diameter Φ50mm, length 180mm. The mesh guide tube is made of aluminum, the diameter of the guide tube is 5mm, the length is 165mm, and the number is 1. The mesh guide tube is placed in the cylinder. Filling AB type TiFe hydrogen storage alloy powder. The gas valve is connected with the barrel through the connecting head, and the connecting head is equipped with a filter. Vacuumize the hydrogen storage device to 150Pa and fill it with hydrogen gas with a purity of 99.99% and a pressure of 2-4 MPa. The hydrogen storage alloy in the hydrogen storage device starts to absorb hydrogen and gradually converts into hydrides. The hydrogen alloy is completely converted into a metal hydride. After the first activation is completed, the hydrogen storage device can be put into use after 4 hydrogen charging and discharging operations. Test results: Compared with other types o...

Embodiment 2

[0019] The internal structure and shape of the metal hydride hydrogen storage device are: an aluminum alloy cylinder with an outer diameter of Φ120mm and a length of 480mm. The mesh guide tube is made of copper, the diameter of the guide tube is 10mm, the length is 455mm, and the number is 3. The mesh guide tube is evenly placed in the cylinder along the axis of the cylinder. Filling AB 5 Type mixed rare earth hydrogen storage material MmNi 4.5 Cr 0.5 alloy powder. The gas valve is connected with the barrel through the connection head, and the gas valve is equipped with a filter. The activation process is the same as in Example 1, and the number of activations is 3 times. Test results: Compared with other types of hydrogen storage, the reserved space of the hydrogen storage is reduced by 38%. After 1000 repeated hydrogen absorption and desorption operations at room temperature, the hydrogen storage device is intact, and the hydrogen storage capacity and hydrogen absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com