CCD camera monitoring module of ultrafine electric spark machine tool

A technology for processing machine tools and monitoring modules, which is applied in the monitoring of processing processes, CCD camera modules, and CCD camera monitoring modules, can solve problems such as difficulty in visual observation, and achieve the effects of high monitoring accuracy, convenient processing operations, and high processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

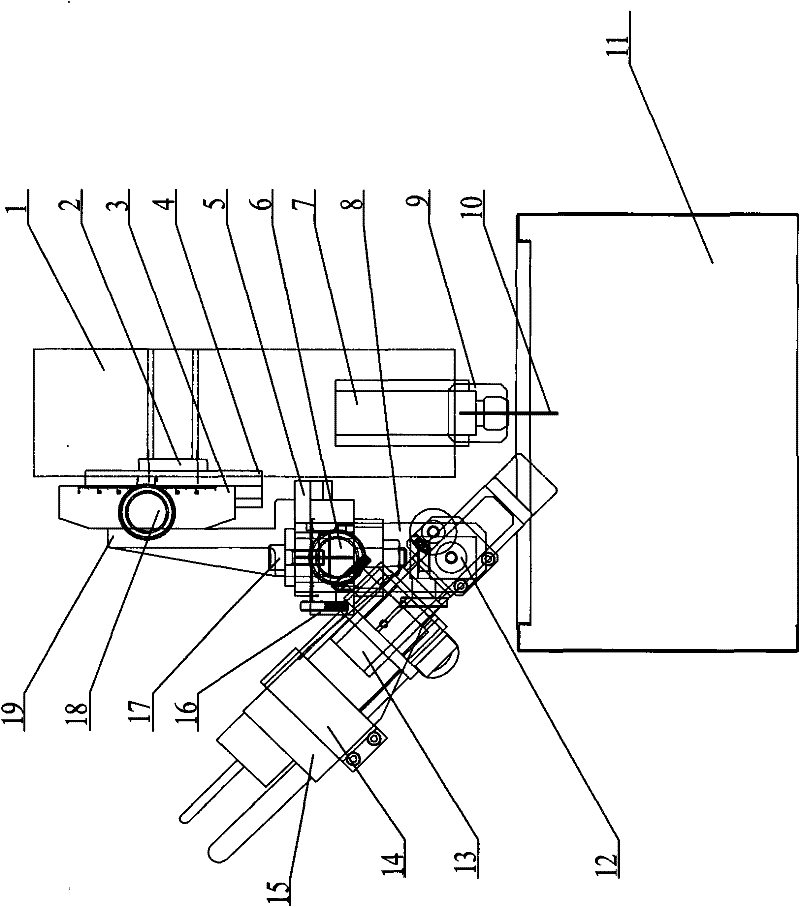

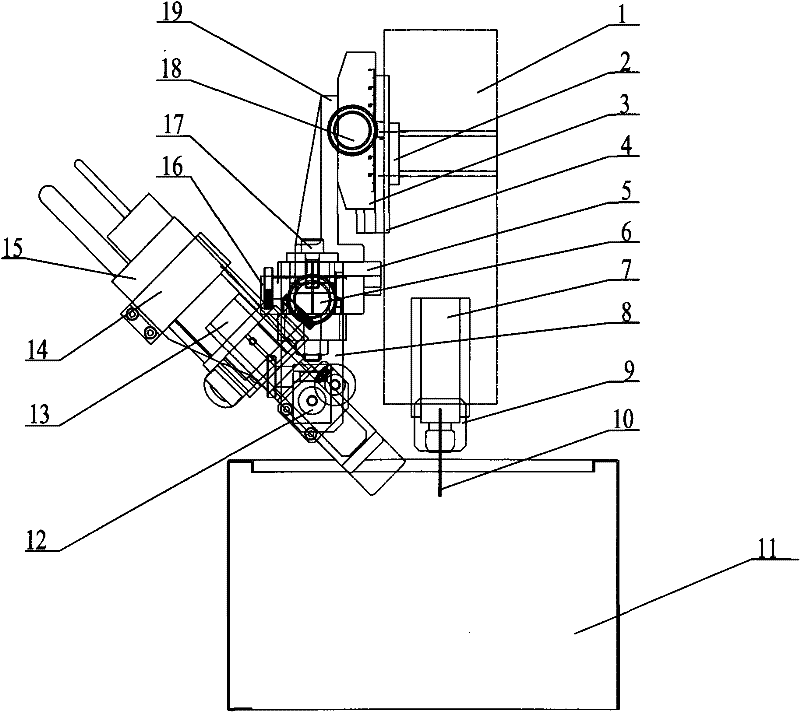

[0010] Such as figure 1 As shown: the present invention includes a machine tool body 1, a moving control rod 2, a vertical slide plate 3, a vertical slide rail 4, a horizontal slide rail 5, a horizontal adjustment handle 6, a spindle 7, an insert track 8, a spindle protection shell 9, and an electrode wire 10 , working fluid tank 11, hinged shaft 12, fixed insert 13, camera protective case 14, camera 15, horizontal slide plate 16, fastening bolt 17, vertical adjustment handle 18 and slide table connecting plate 19.

[0011] Such as figure 1 As shown: one end of the machine tool body 1 is provided with a mobile control rod 2, and the mobile control rod 2 can move relative to the machine tool body 1; one end of the mobile control rod 2 is provided with a vertical slide rail 4, and on the vertical slide rail 4 A vertical slide 3 is provided. The vertical slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com