A working platform for engineering quality management

A technology of working platform and engineering quality, applied in the direction of measuring device, mechanical diameter measurement, mechanical measuring device, etc., can solve problems such as trouble, loss of building materials, and heavy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

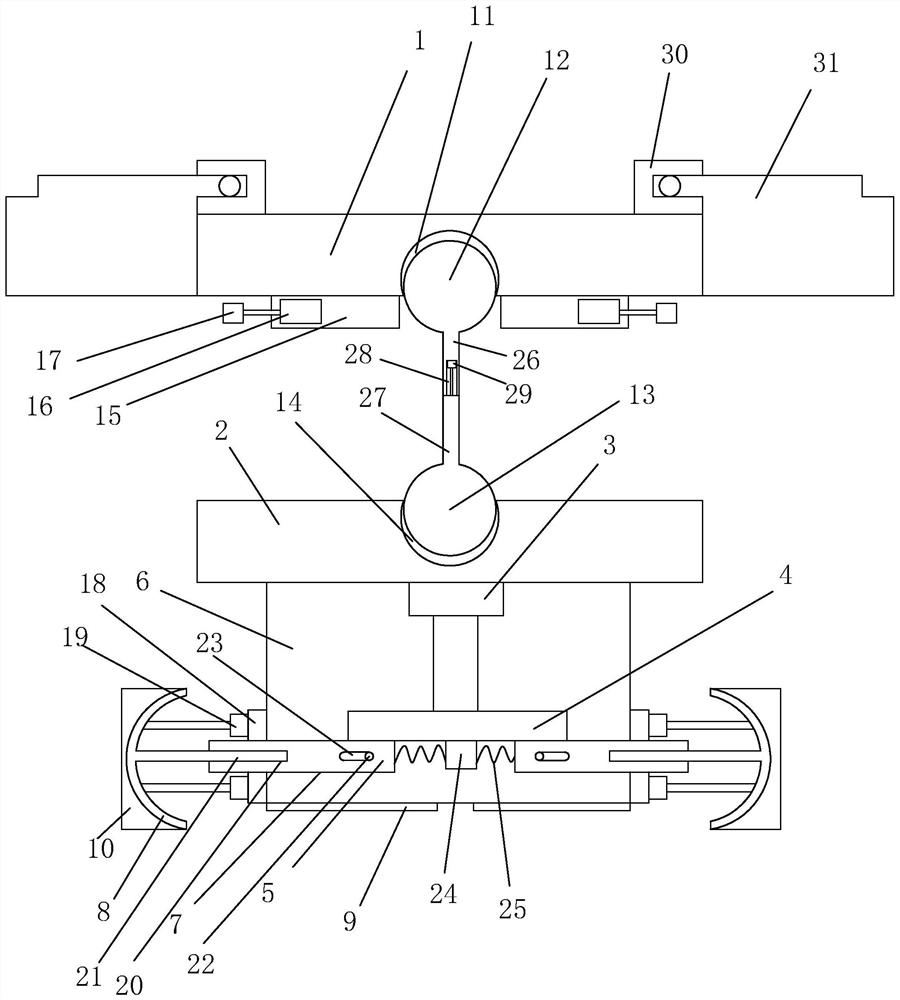

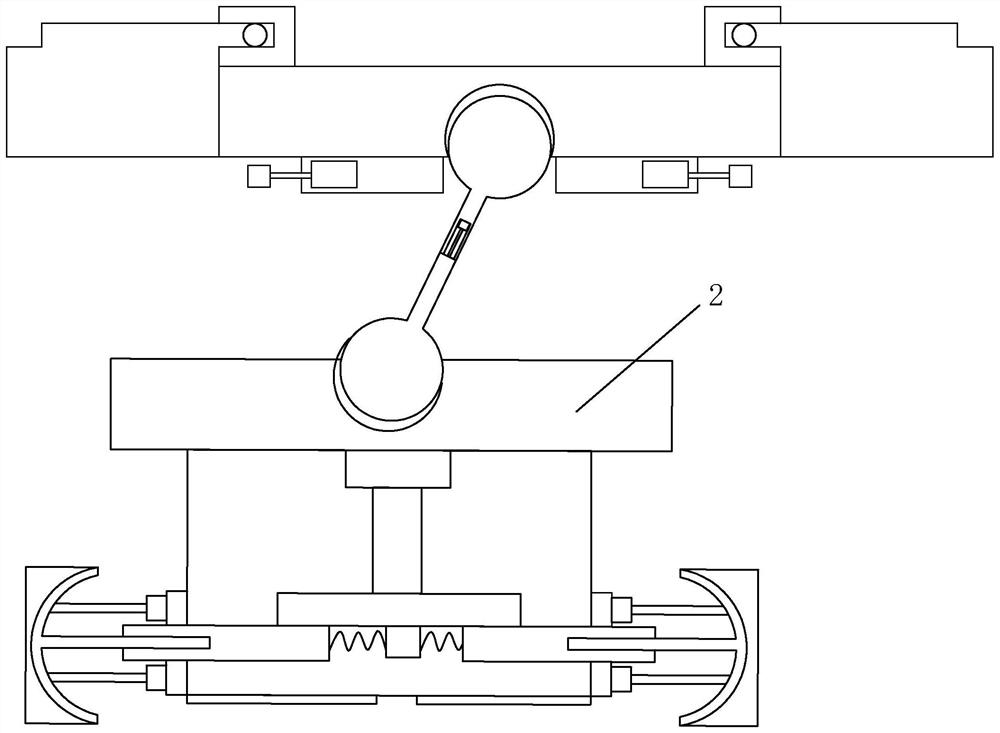

[0038] Referring to the drawings further illustrate the present invention.

[0039] A system for project quality management work platform, such as Figure 1-9 , The body 35 includes a platform, the platform body 35 is provided with a housing 1a, 1a of the housing is provided with a slotted upper casing 1a, 2a communicating with said slot and are disposed below the opening 2a 2a slotted communication groove 3a, inside the housing 1a is provided with a fixing slot 2a of the motor is located below 4a, 4a of the fixed motor output shaft is connected to a connecting rod disposed perpendicular to the output shaft 5a, 5a remote from the connecting rod One end 4a of the motor is provided with a fixed placement block 6a, 6a of the block is placed is provided with a receiving groove 7a, the receiving groove opening towards the groove 7a of the partition 3a, the bottom of the case 1a is provided with an outlet 8a, the sub-grooves 3a a closed lower end is provided with a cylinder 9a, 9a are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com