Disassembling and assembling device for heavy wheel

A wheel and heavy-duty technology, which is applied in the field of heavy-duty wheel disassembly and assembly devices, can solve the problems of high labor intensity in disassembly and assembly of wheels, difficulty in moving and centering, and poor stress conditions, so as to facilitate vehicle-mounted and field use, improve stress conditions, The effect of high centering rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

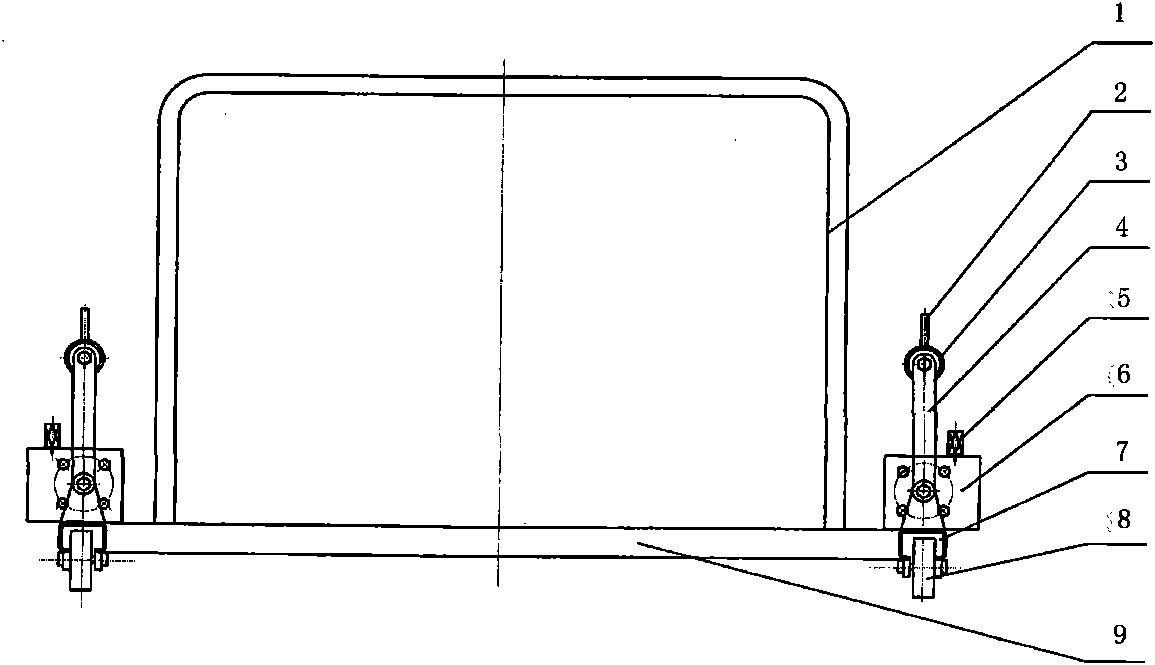

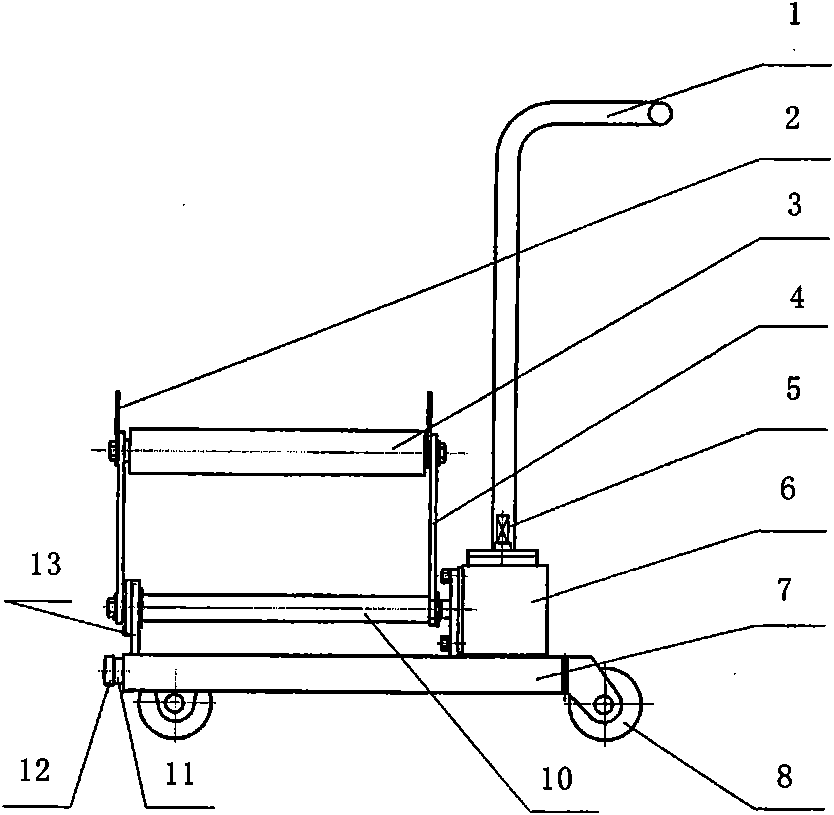

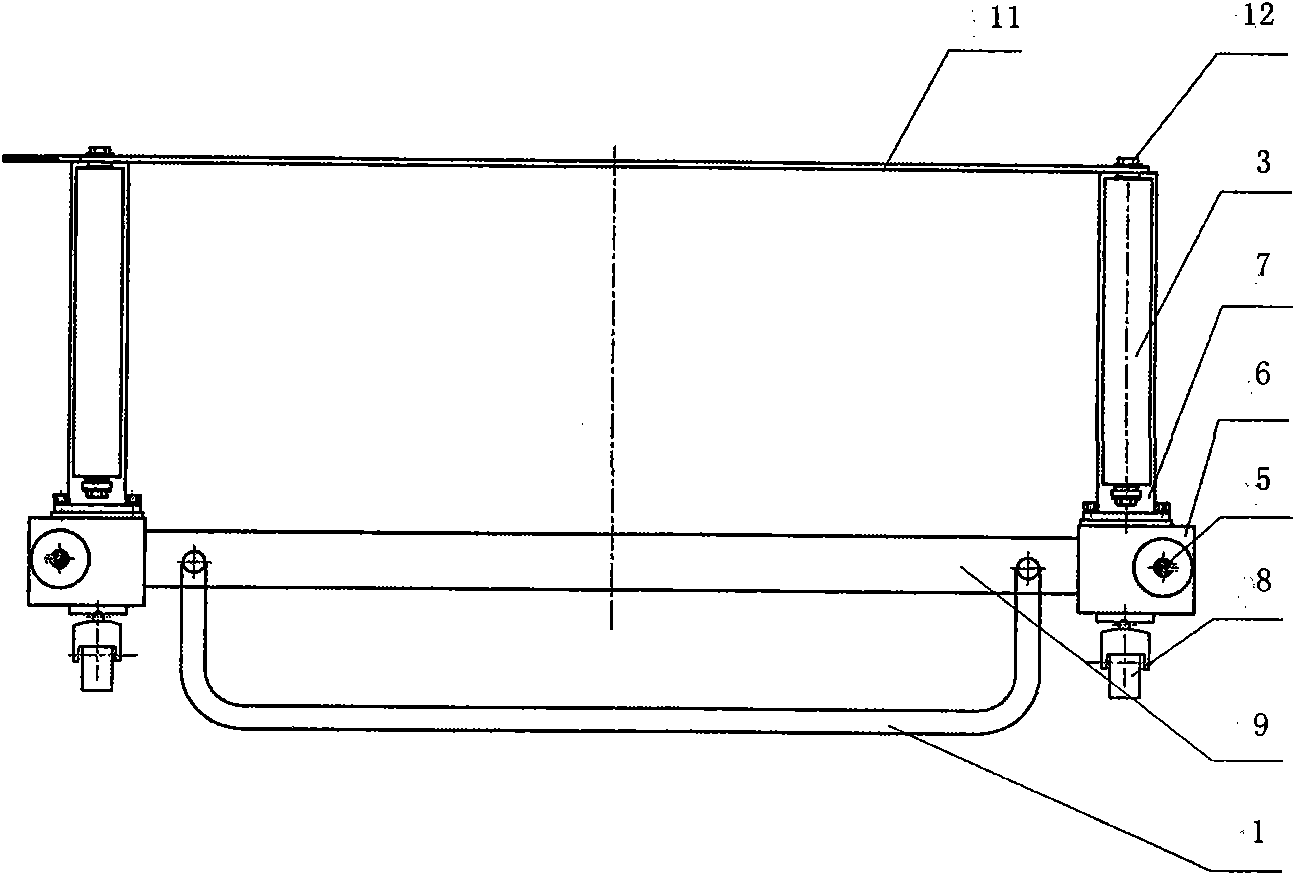

[0015] A heavy-duty wheel dismounting device: such as figure 1 and image 3 As shown, two side supports 7 are symmetrically fixed on the two ends of the crossbeam 9, and the two side supports 7 are respectively perpendicular to the crossbeam 9 on the horizontal plane to form a "U" shaped frame, and the crossbeam 9 is equipped with handrails 1, two Rollers 8 are respectively housed below the two ends of the side support 7 . For convenience of description, it is assumed that the open end of the "U" shape frame is the front end, and the end where the armrest 1 is housed is the rear end. The two speed reducers 6 are mounted on one end (rear end) of the two side brackets 7 respectively, and the other end (front end) of the two side brackets 7 are respectively provided with a short pin shaft 12, and the additional pull rod 11 is movably stuck on the On the two short pin shafts 12.

[0016] Such as figure 2 As shown, the two swing link shafts 10 are respectively installed above ...

Embodiment 2

[0019] A heavy-duty wheel dismounting device: the input end 5 of the reducer 6 is driven by a motor. All the other are with embodiment 1.

[0020] The U"-shaped frame of this specific embodiment is a simply-supported structure supported by rollers 8, which greatly improves the stress conditions, easily realizes miniaturization and light weight, and is convenient for vehicle and field use, especially for the side bracket 7 to fork into the lower part of the tire; The two rotating rollers 3 can realize the rotation of the wheel around the central axis of the tire when the tire is installed, and then realize the centering of the rim screw hole; the handrail installed on the U" frame can conveniently make the device move forward and backward; the set Additional tie rod 11 can increase the rigidity of U-shaped frame horizontal plane.

[0021] The swing angle of the swing link 4 is controlled by the reducer 6 to drive the swing link shaft 10, which can realize the left and right or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com