Method for producing composite or farrago structure

A technology for strengthening structure and compounding, applied in the direction of coating, etc., can solve the problems of high cost and work consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

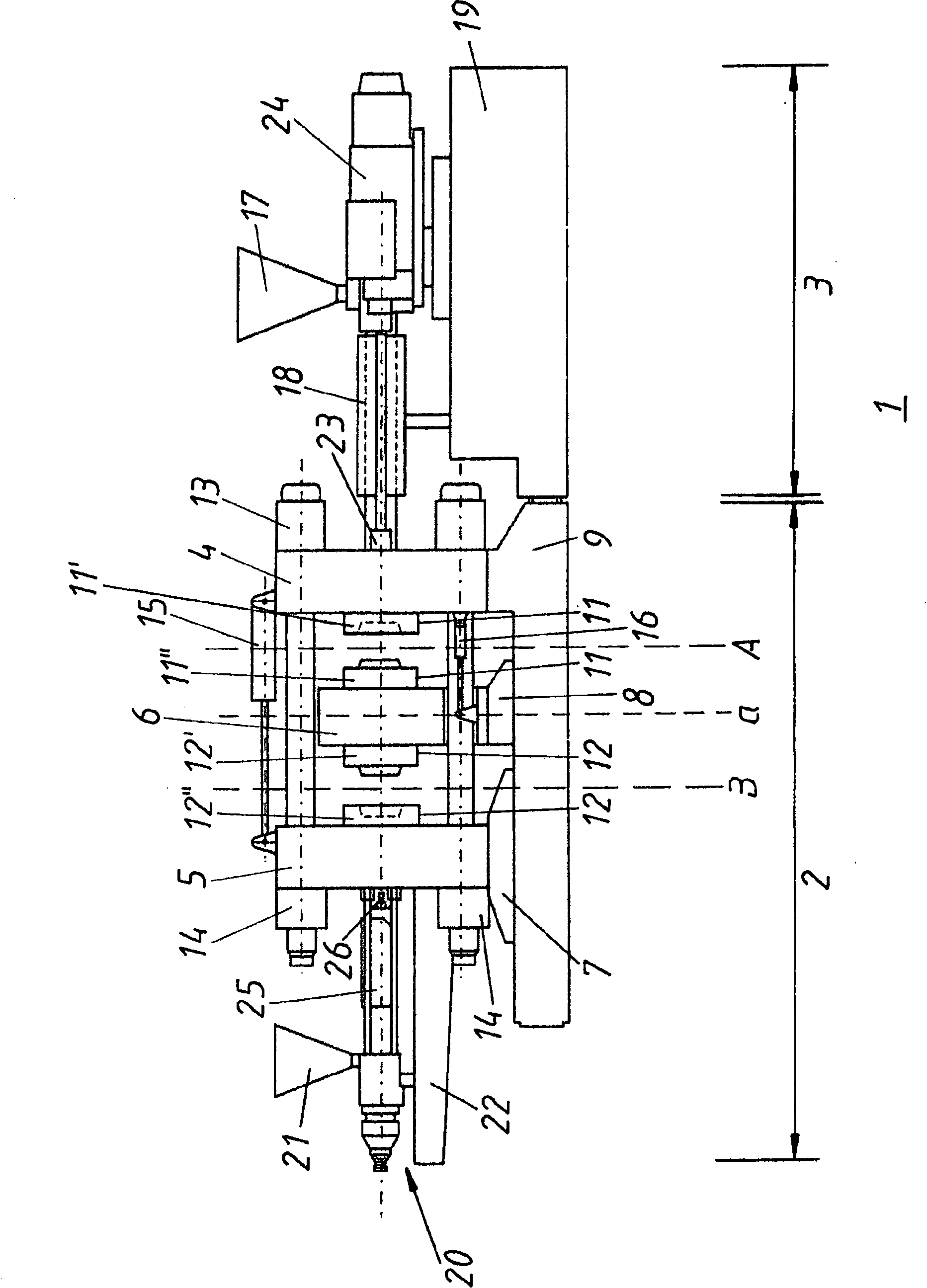

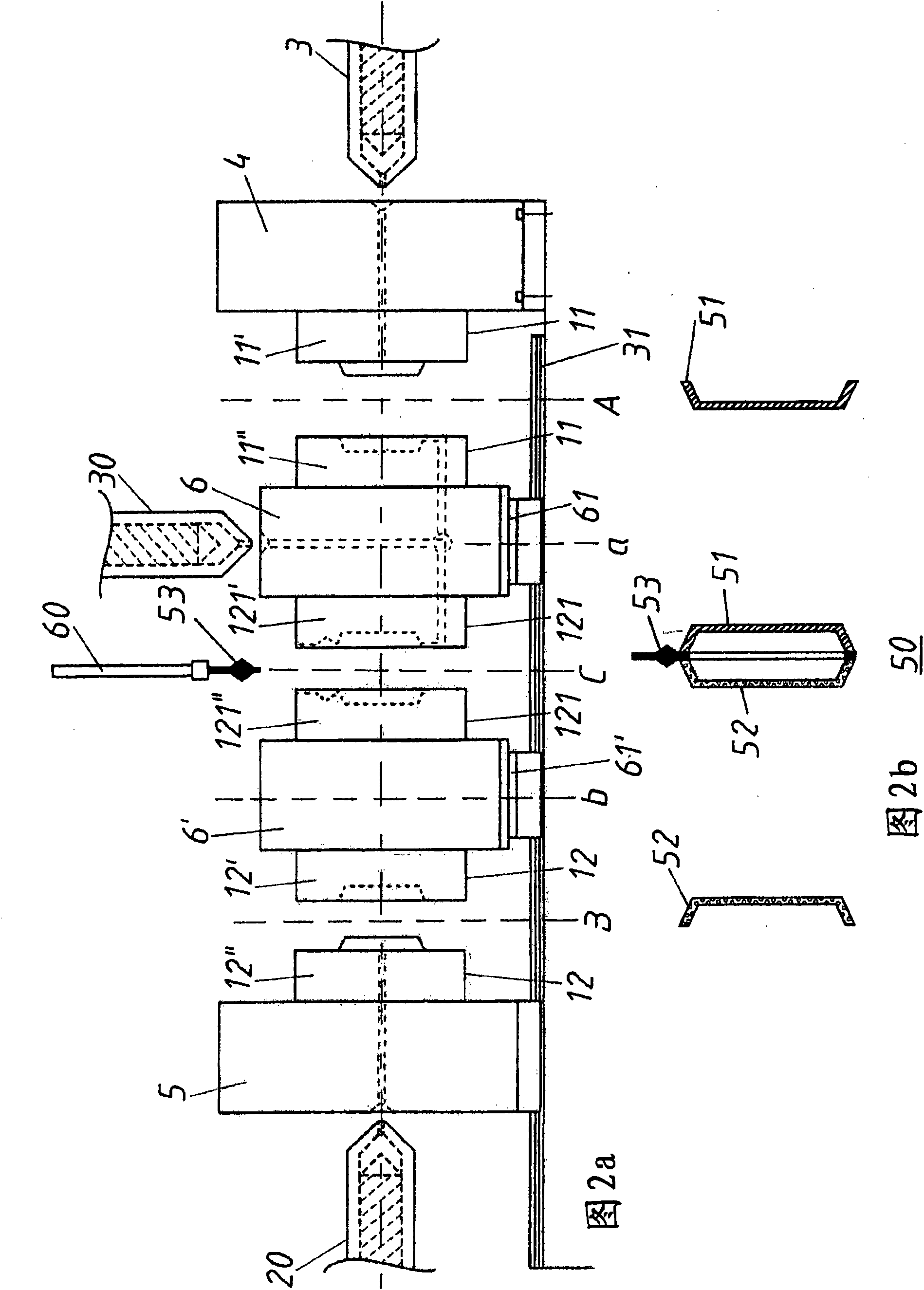

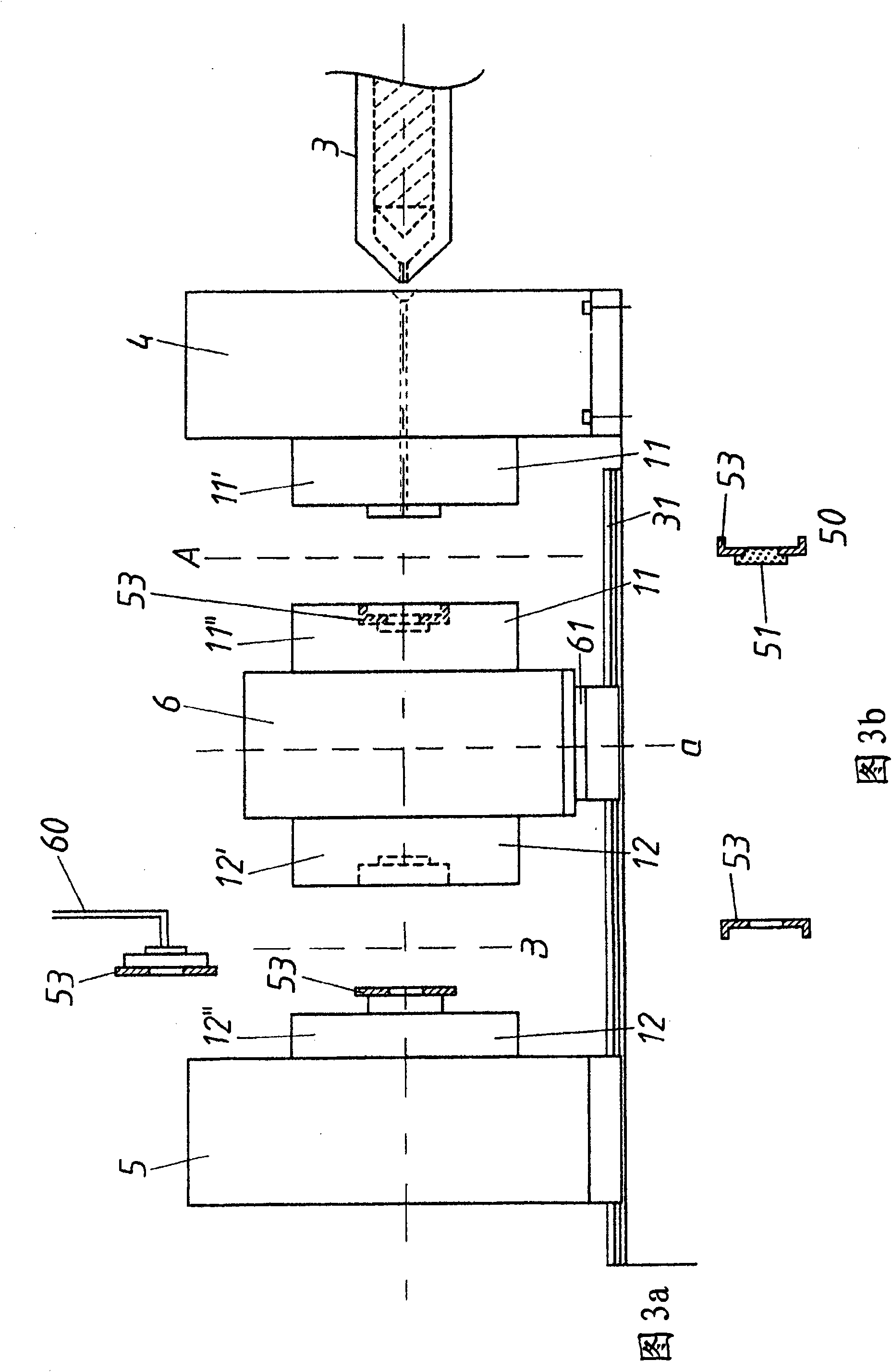

[0029] exist figure 1 An injection molding machine 1 is shown in , which can be used for the method according to the invention. The injection molding machine 1 here has a clamping unit 2 and a plasticizing and injection unit 3 in a known manner. The mold clamping unit 2 includes a fixed mold base plate 4 fixedly arranged on a frame 9 . Also be provided with a movable mold base plate 5 in addition, this mold base plate is in a for example in Figure 2a The slide block 7 on the slide rail 31 shown in the figure can move linearly along the column 10. The movement of the movable base plate 5 is carried out by means of travel cylinders 16 with piston-cylinder units away from and towards the movable (fixed) cover plate 4 . In order to fix the movable mold base plate 5 in the desired position, a locking mechanism 14 is provided on the column 10 , which secures the mold base plate 5 to the column 10 with a positive and / or frictional fit. superior. Furthermore, a turntable plate 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com