Rear board combination

A backplane and mainboard technology, which is applied in instrumentation, cooling/ventilation/heating transformation, electrical digital data processing, etc., can solve problems such as the inability to combine the radiator backplane and the inconvenience of installing the radiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

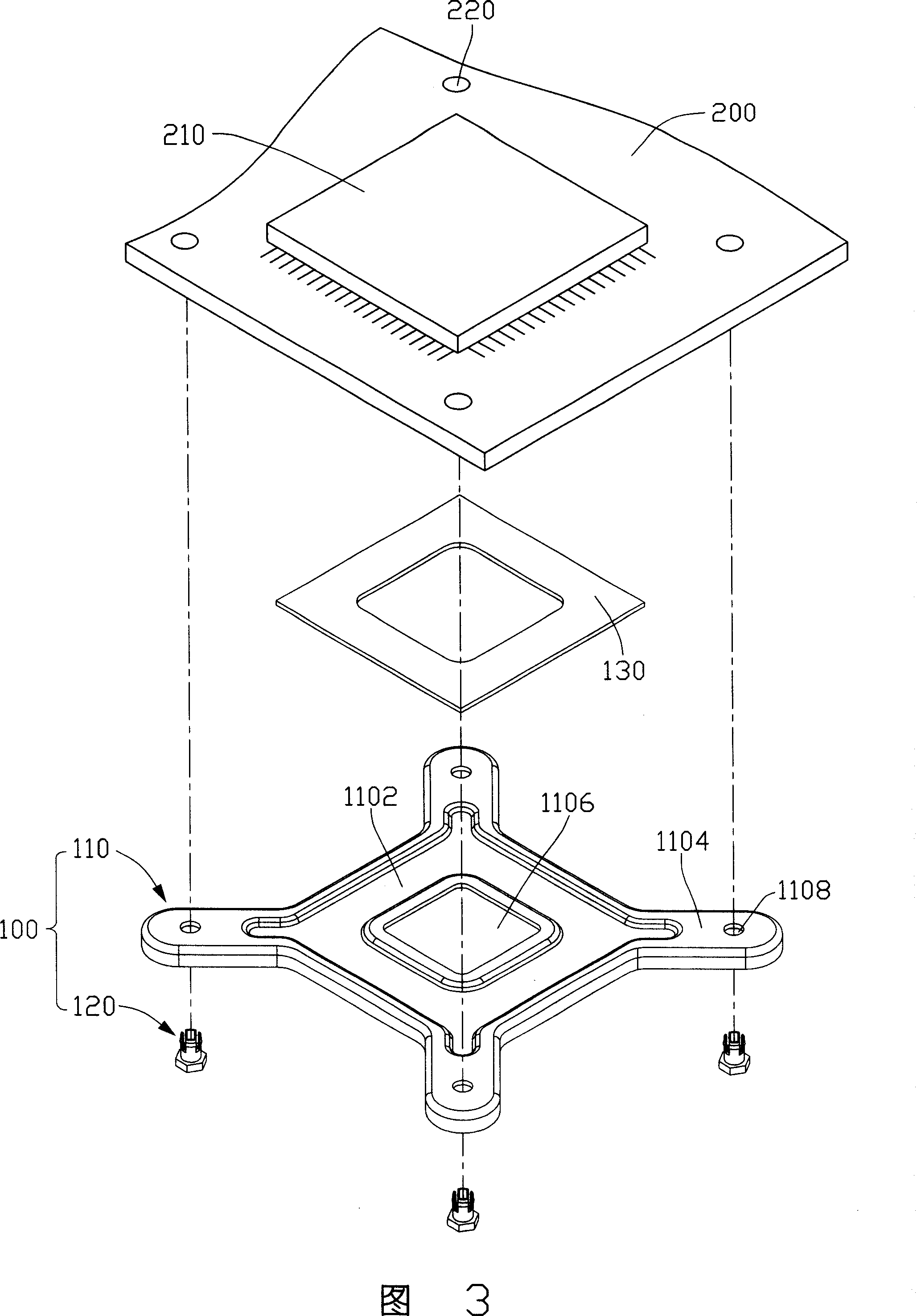

[0016] Please refer to FIG. 3 , the backplane assembly 100 of the present invention includes a backplane 110 and several fixing columns 120 , wherein these fixing columns 120 can snap fit with the motherboard 200 after passing through the backplane 110 , so that the backplane 110 can be pre-installed. It is installed on the bottom surface of the motherboard 200 to increase the strength of the motherboard 200 .

[0017] Wherein, a central processing unit 210 is installed at a corresponding position above the main board 200 , and a through hole 220 is correspondingly opened on the main board 200 around the central processing unit 210 , so that the fixing posts 120 can pass through and cooperate with each other.

[0018] The backboard 110 is roughly cross-shaped, and includes a substantially rectangular abutting portion 1102 and four fixing arms 1104 extending outward from the four corners of the abutting portion 1102, wherein the proximal end of each fixing arm 1104 A perforatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com