Liquid crystal polyester composition and preparation method thereof

A technology of liquid crystal polyester and its composition, which is applied in the field of liquid crystal polyester composition and its preparation, to achieve the effects of good fluidity, high dielectric constant, and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

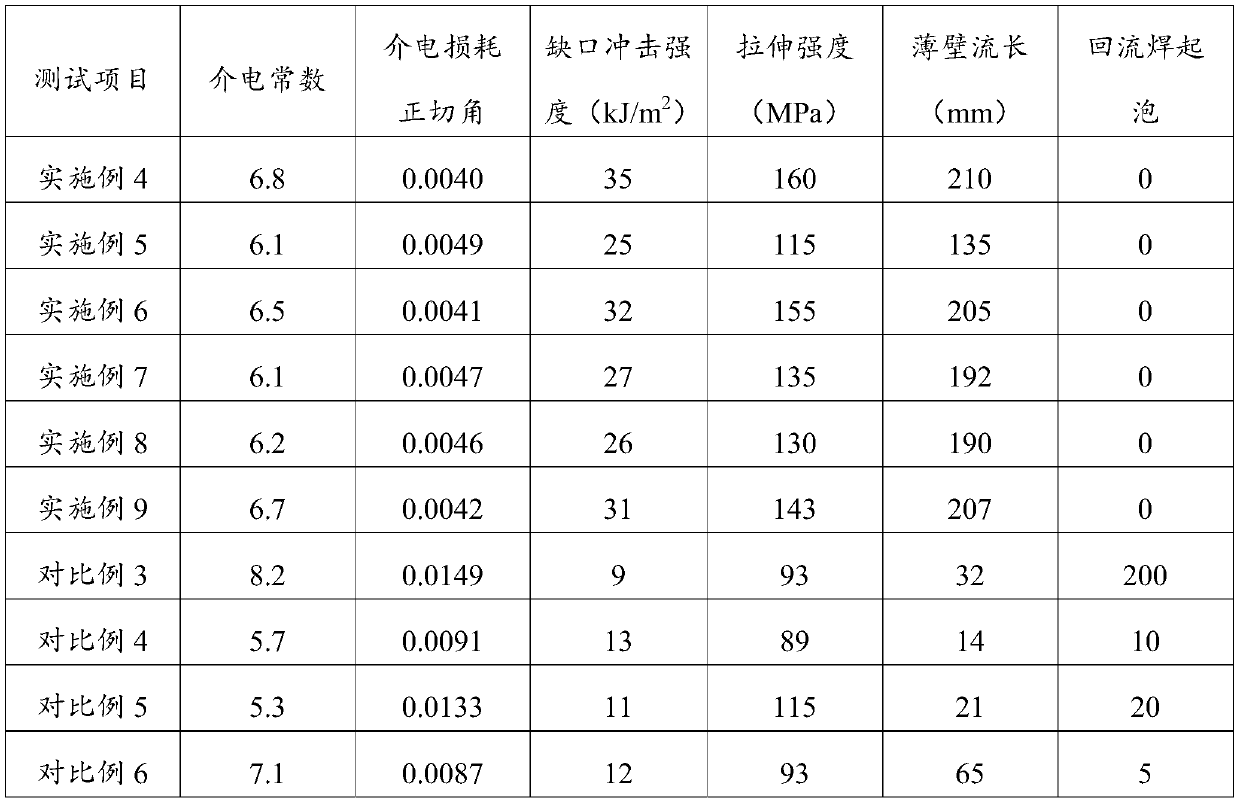

Examples

Embodiment 1

[0042] In a reactor equipped with a stainless steel C-type stirrer, torque gauge, nitrogen conduit, thermometer, pressure gauge and reflux condenser, 994.5 g of p-hydroxybenzoic acid, 299.0 g of terephthalic acid, 99.7 g of isophthalic acid Dicarboxylic acid, 446.9 g of 4,4'-dihydroxybiphenyl, 1347.6 g of acetic anhydride, 200.0 g of acetic acid. The reactor was purged by evacuation and flushing with dry nitrogen, and 0.18 g of 1-methylimidazole was added. Under nitrogen protection, with stirring at 75 rpm, the temperature was raised to 150° C. over 60 minutes and refluxed by keeping at this temperature for 60 minutes. After adding 13.0 g of benzylamine and 1.84 g of calcium acetate into the reactor, the temperature was raised to 340° C. within 20 min. During this time, by-product acetic acid was removed by distillation. After keeping the temperature at 340°C for 30 minutes, gradually reduce the pressure to about 100 Pa within 20 minutes and keep the vacuum until the torque ...

Embodiment 2

[0044] In a reactor equipped with a stainless steel C-type stirrer, torque gauge, nitrogen conduit, thermometer, pressure gauge and reflux condenser, 994.5 g of p-hydroxybenzoic acid, 399.0 g of terephthalic acid, 480 g of 1,5 '-Dihydroxynaphthalene, 1347.6 g of acetic anhydride, 200.0 g of acetic acid. The reactor was purged by evacuation and flushing with dry nitrogen, and 0.18 g of 1-methylimidazole was added. Under nitrogen protection, with stirring at 75 rpm, the temperature was raised to 150° C. over 60 minutes and refluxed by keeping at this temperature for 60 minutes. After adding 13.0 g of benzylamine and 1.84 g of calcium acetate into the reactor, the temperature was raised to 340° C. within 20 min. During this time, by-product acetic acid was removed by distillation. After keeping the temperature at 340°C for 30 minutes, gradually reduce the pressure to about 100 Pa within 20 minutes and keep the vacuum until the torque increases by more than 30%. The reaction is ...

Embodiment 3

[0046] In a reactor equipped with stainless steel C-type stirrer, torque meter, nitrogen conduit, thermometer, pressure gauge and reflux condenser, add 600g of p-hydroxybenzoic acid, 376g of 2-hydroxy-6-naphthoic acid, 299.0g of p-hydroxybenzoic acid Phthalic acid, 446.9 g of 4,4'-dihydroxybiphenyl, 1347.6 g of acetic anhydride, 200.0 g of acetic acid. The reactor was purged by evacuation and flushing with dry nitrogen, and 0.18 g of 1-methylimidazole was added. Under nitrogen protection, with stirring at 75 rpm, the temperature was raised to 150° C. over 60 minutes and refluxed by keeping at this temperature for 60 minutes. After adding 13.0 g of benzylamine and 1.84 g of calcium acetate into the reactor, the temperature was raised to 340° C. within 20 min. During this time, by-product acetic acid was removed by distillation. After keeping the temperature at 340°C for 30 minutes, gradually reduce the pressure to about 100 Pa within 20 minutes and keep the vacuum until the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com