Locking and sealing electric connector

An electrical connector, a compact technology, applied in the direction of connection, connecting device components, circuits, etc., can solve the problems of sealing failure, the sealing failure of the end face of the plug shell and the rubber ring of the socket shell, etc. The effect of convenient locking operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

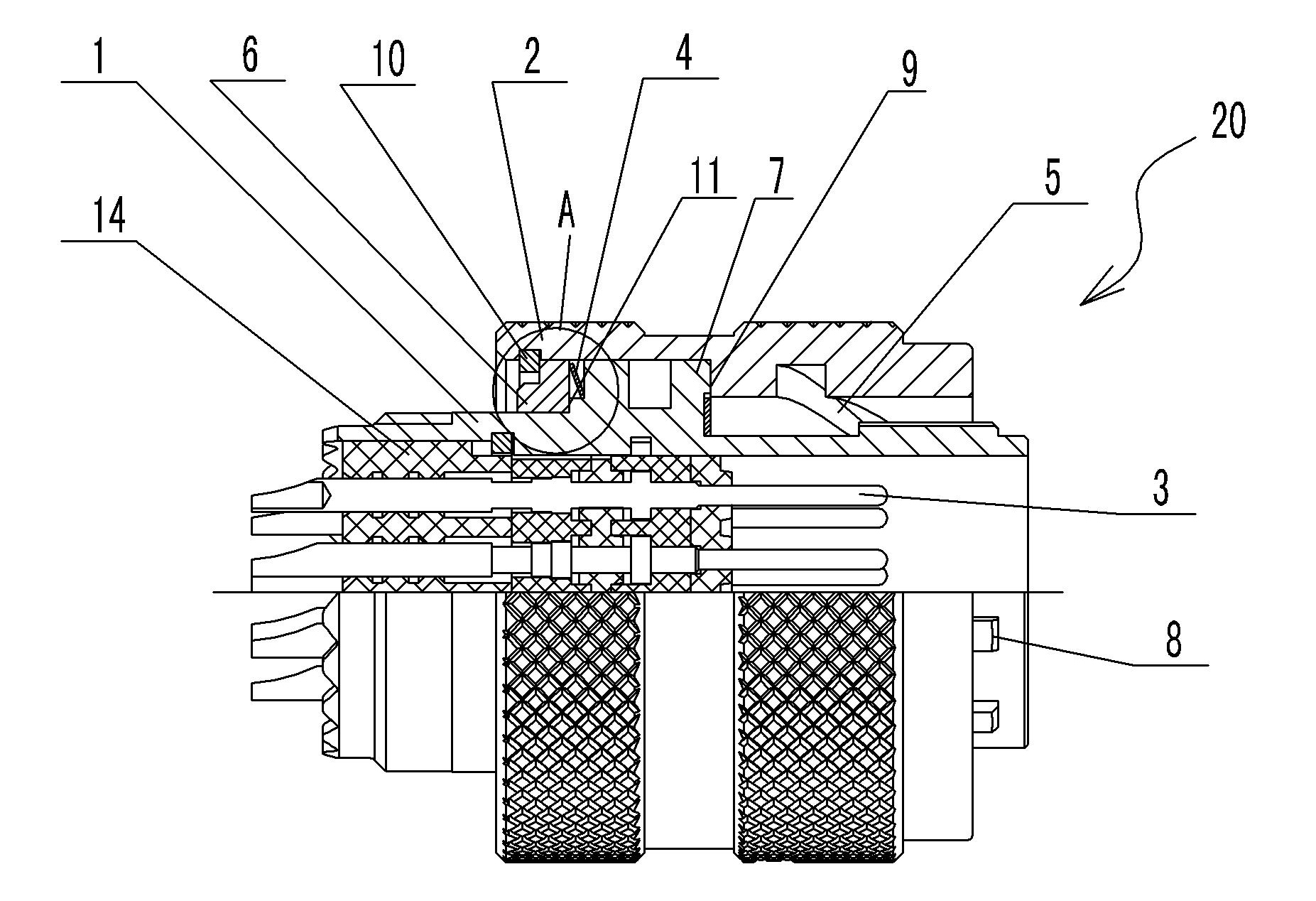

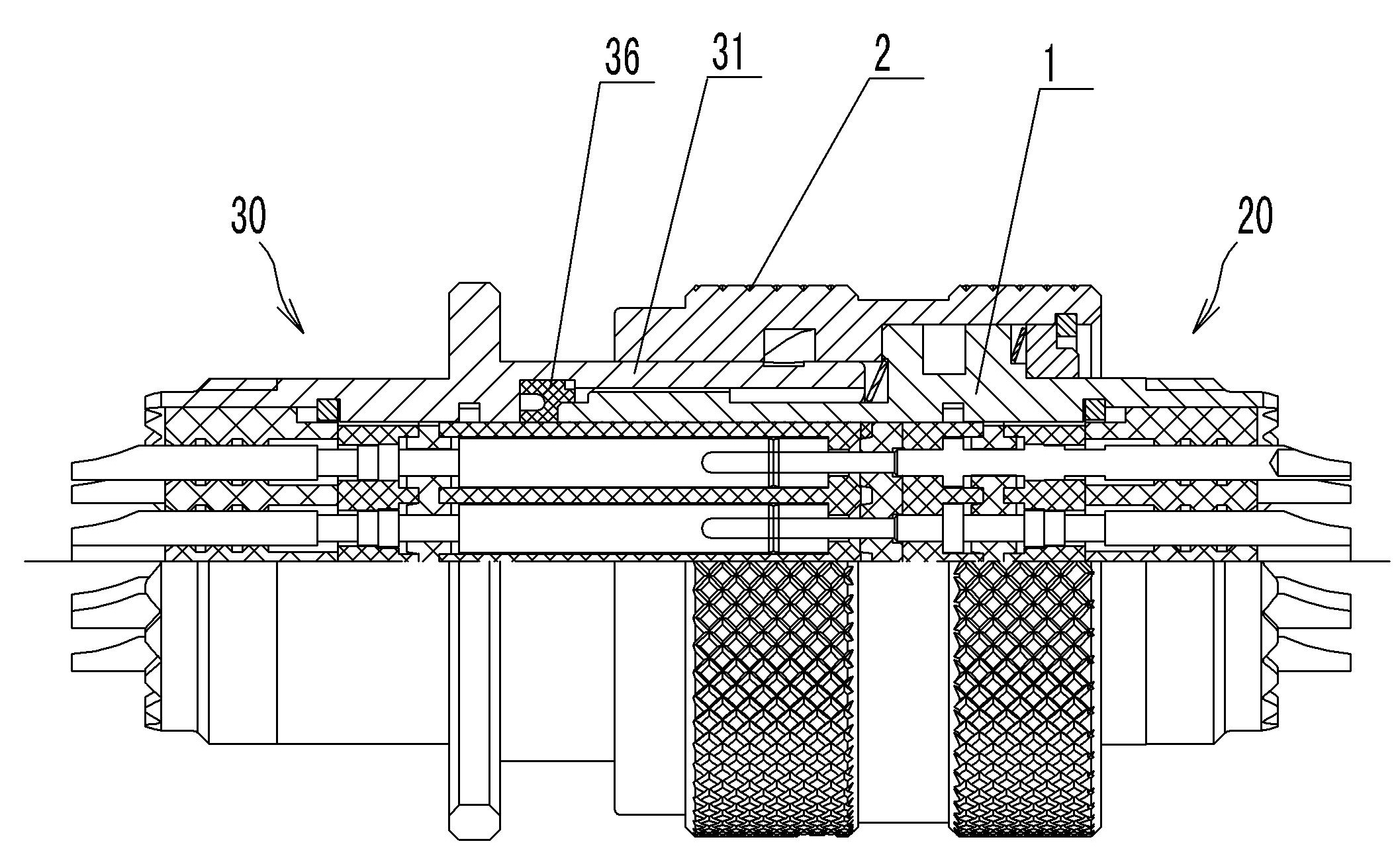

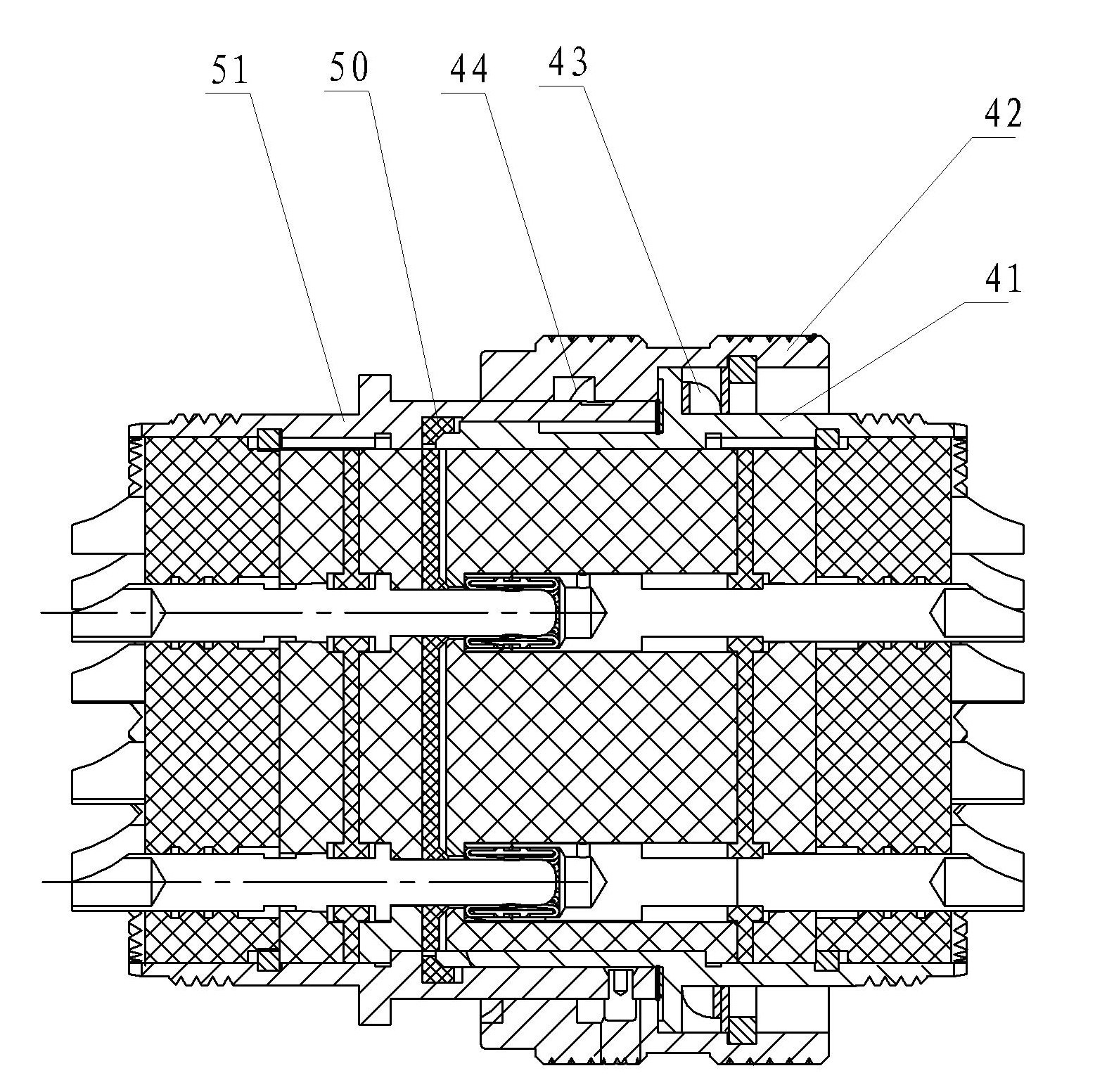

[0025] Such as Figure 1 to Figure 5 As shown, the plug 20 of the present invention has a cylindrical shape as a whole, and the front and rear ends are respectively a plug-in terminal and a terminal. A plug insulator 14 is installed in the housing 1, and a plug contact 3 protruding from the front end of the plug insulator 14 is installed in the plug insulator 14. A plurality of guide keys 8 are extended, and the inner wall of the connecting cap 2 is provided with three curved grooves 5 extending backward from the outer end of the connecting cap. Staple holes 12 for snapping in of the staples on the socket housing.

[0026] A rigid thrust structure is provided between the outer peripheral surface of the plug housing 1 and the inner wall of the connecting cap 2 behind the staple hole 12, and the rigid thrust structure is axially rigid and limited. The rigid thrust structure of the connection cap on the inner wall of the connection cap 2 and the rigid thrust structure of the pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com