Bark shredding machine

A shredder and bark technology, which is applied in the field of biomass raw material recycling, can solve the problems of late development of biomass ginseng power generation technology, unsatisfactory crushing effect, and influence on ginseng burning effect, so as to achieve good cutting effect and feed Uniform and reliable, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

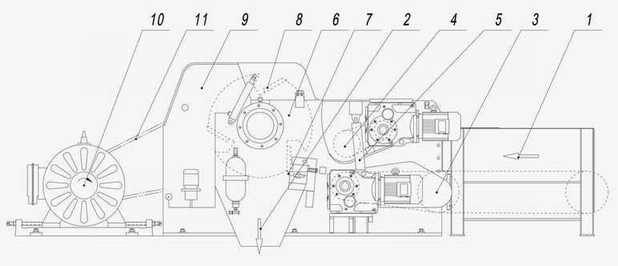

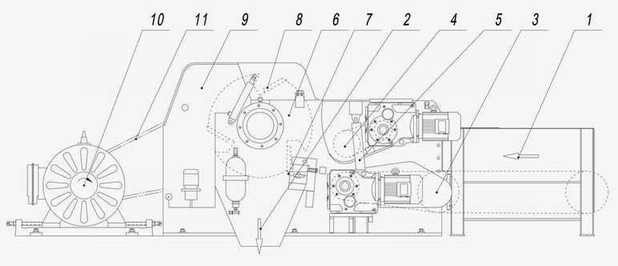

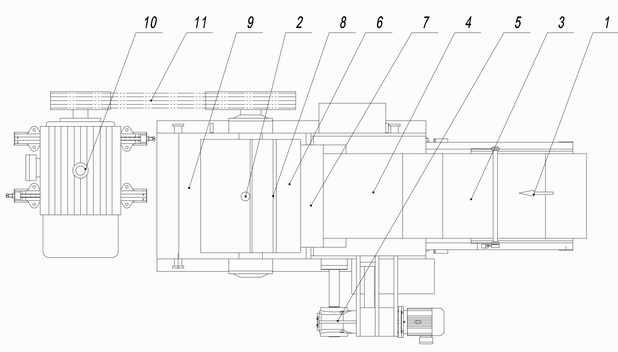

[0017] Such as figure 1 , figure 2 As shown, the bark shredder of the present invention is mainly composed of a lower conveying chain 3 and an upper conveying chain 4, a hydraulic cylinder 5, a cutter roller group 6, and a casing 9. The upper conveying chain is controlled by a hydraulic cylinder, and can be lifted and lowered freely. It has the function of rolling and compacting the materials. In this way, the upper and lower conveying chains and the hydraulic cylinder 5 are combined to form a rolling feeding mechanism. The cutting device is composed of the casing 9 and the cutter roller group 6. The cutter roller is a cylindrical structure. There are 3 to 6 flying knives distributed on the knife roller, and the casing is a cylindrical structure that can be opened and closed, and a row of fixed bottom knives is arranged on the casing.

[0018] When w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com