Thermoplastic mould cup trimming device

A thermoplastic mold and edge trimming technology, which is applied in metal processing and other directions, can solve the problems of irregular mold cup edges, inconsistent cutting standards, and low cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

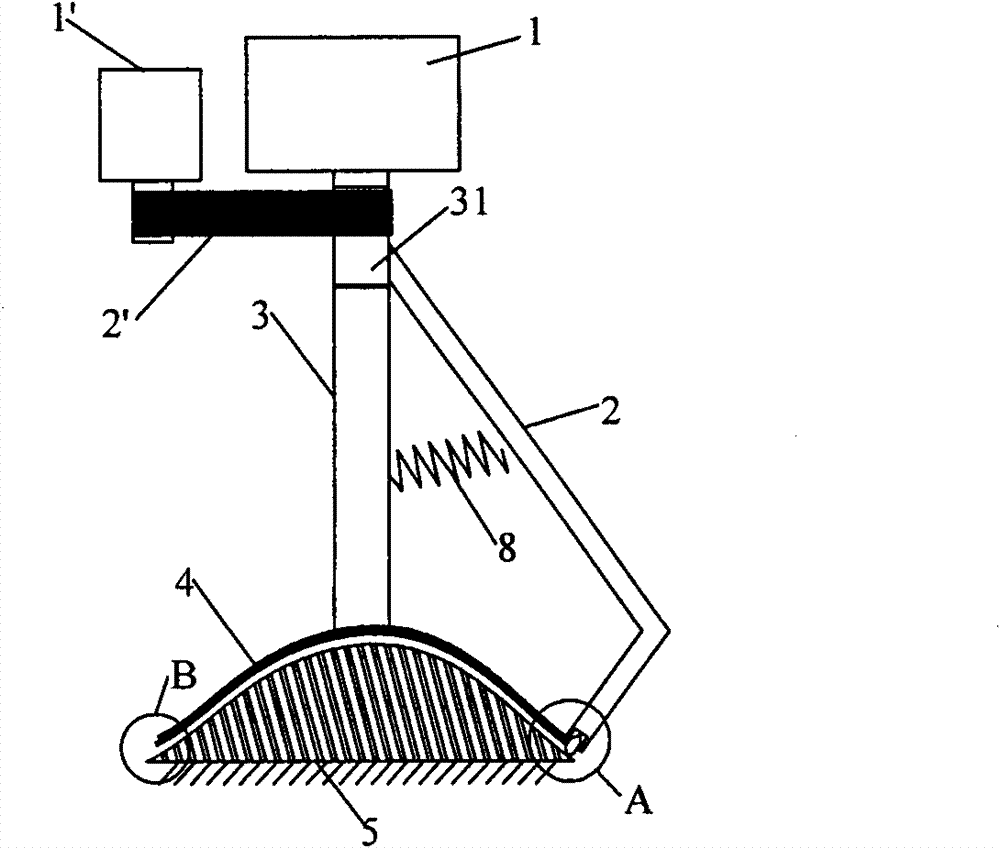

[0030] Such as figure 1 and figure 2 As shown, the present invention provides an embodiment of a thermoplastic mold cup trimming device.

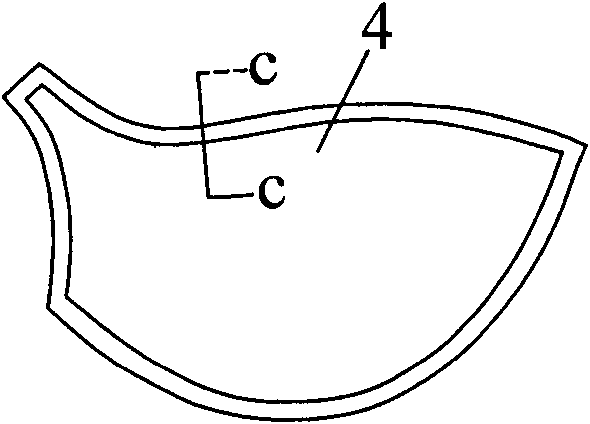

[0031] The underwear thermoplastic mold cup trimming device includes: a base 5 having the same shape as the mold cup, and the trimming device also includes an edge-seeking guide device and a cutter device matched with the edge-finding guide device, and the edge-finding guide device It is connected with the rotating shaft of the drive motor 1'. Specifically, the edge-seeking guide device includes a pressing part 4 having the same shape as the mold cup, a telescopic device 1 and an elastic part 8 fixed to the pressing part 4, wherein the telescopic device 1 is provided with the same Shaft and the runner 11 connected with the drive motor 1' through the transmission part 2', the runner 11 is connected with the connecting rod part 2 provided with the cutter device; Connect with link part 2.

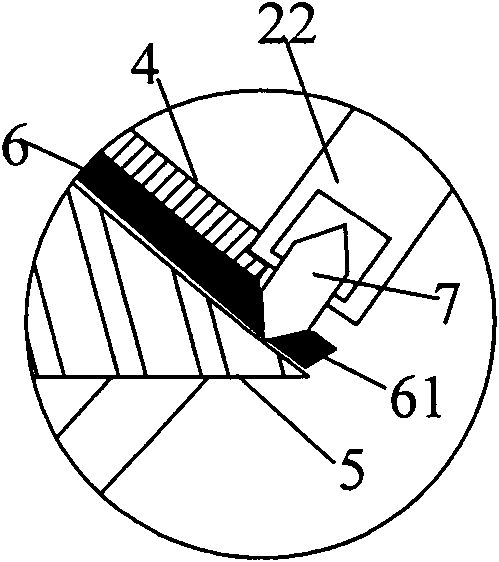

[0032] Such as image 3 As shown, the cutter de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com