Cutting glue machine

A glue applicator and glue technology, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of high intensity of cutting and pasting of reimbursement documents, and achieve the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

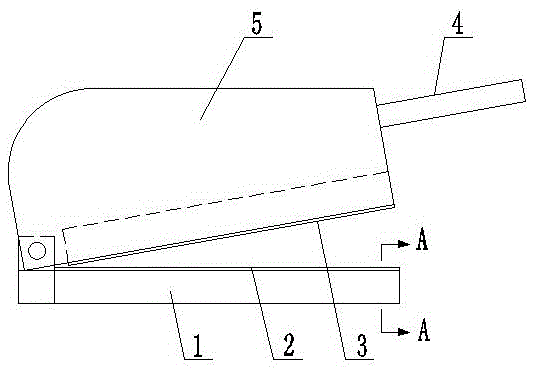

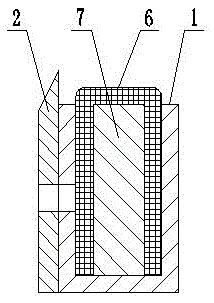

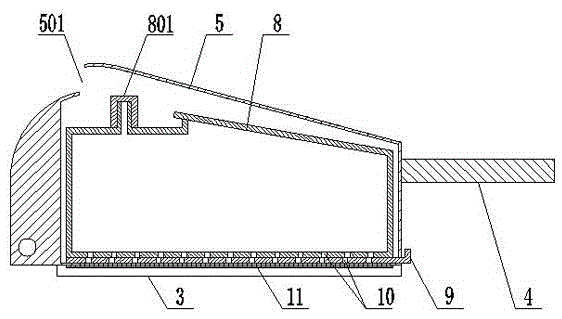

[0014] Such as figure 1 with image 3 As shown, the cutting and gluing machine includes a base 1, an adjustment block 9, a movable frame 5 and a glue box 8 fixed in the inner cavity of the movable frame 5, one end of the movable frame 5 is hinged with the base 1, and the other end is provided with a Handle 4, the upper end of movable frame 5 is provided with the opening 501 that is used to add glue in the glue box 8, is provided with upper end cover 801 on the position corresponding to this opening 501 on the glue box 8, and the lower end of movable frame 5 is provided with for gluing operation. port, the movable frame 5 is provided with a through hole on the side wall opposite to its hinged end, the adjustment block 9 passes through the through hole and is used to seal the port at the lower end of the movable frame 5, and the glue box 8 is located on the adjustment block 9, that is, at the port of the gluing operation at the lower end of the movable frame 5, there is an adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com