An environment-friendly cutting device for imitation leather texture composite fabric

A technology of composite fabric and cutting device, which is applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of reduced work efficiency, distorted cutting, and consume a lot of time and manpower, so as to achieve the effect of improving work efficiency and ensuring neat cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

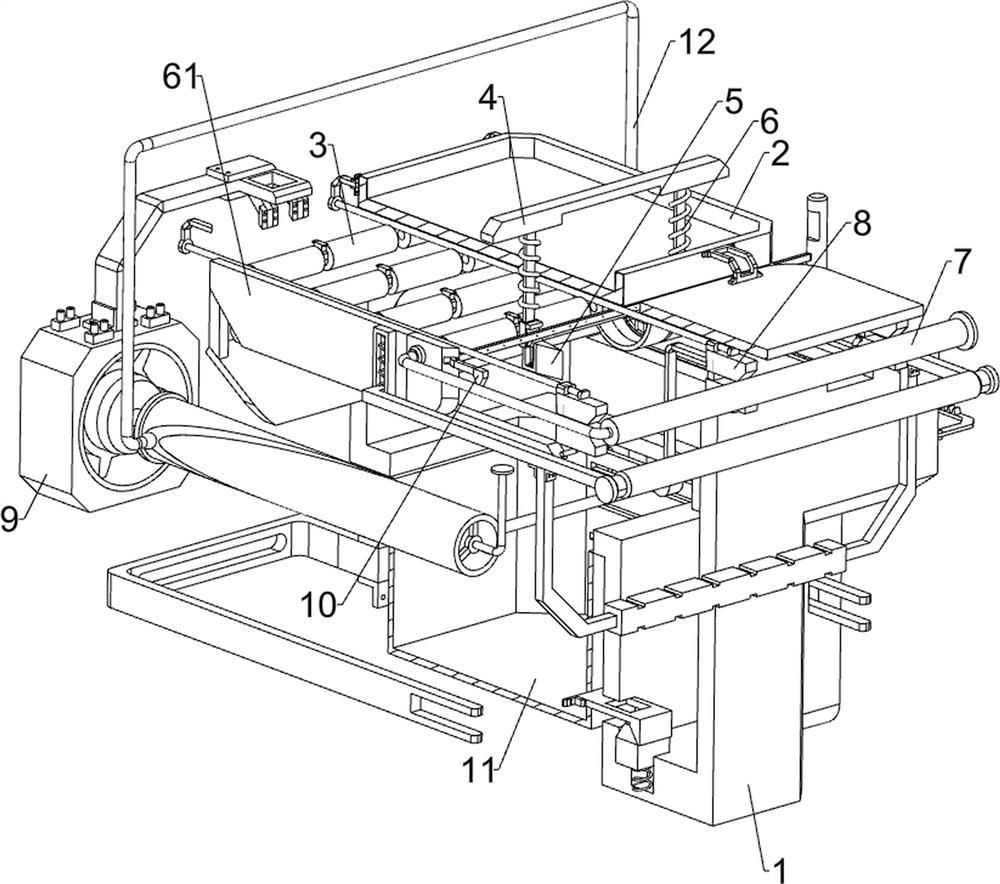

[0039] An environmentally friendly imitation leather texture composite fabric cutting device, such as Figure 1-17 As shown, it includes a workbench 1, a mounting frame 2, a guide cylinder 3, a lifting frame 4, a blade 5, a first spring 6, a dividing plate 61, a flattening assembly 7 and a clamping assembly 8, and the workbench 1 is used to install the entire device , the top of the worktable 1 is fixed with a mounting frame 2 by bolts, and at least two sets of guide cylinders 3 are rotatably arranged on the left and right sides of the bottom of the mounting frame 2. Blades 5 are provided on the left and right sides, a first spring 6 is connected between the left and right sides of the lifting frame 4 and the mounting frame 2, and the left and right sides of the bottom of the mounting frame 2 are fixed with a dividing plate 61 by screws. The top part is provided with a flattening component 7 which is flattened by extrusion, and the bottom of the mounting frame 2 is provided wi...

Embodiment 2

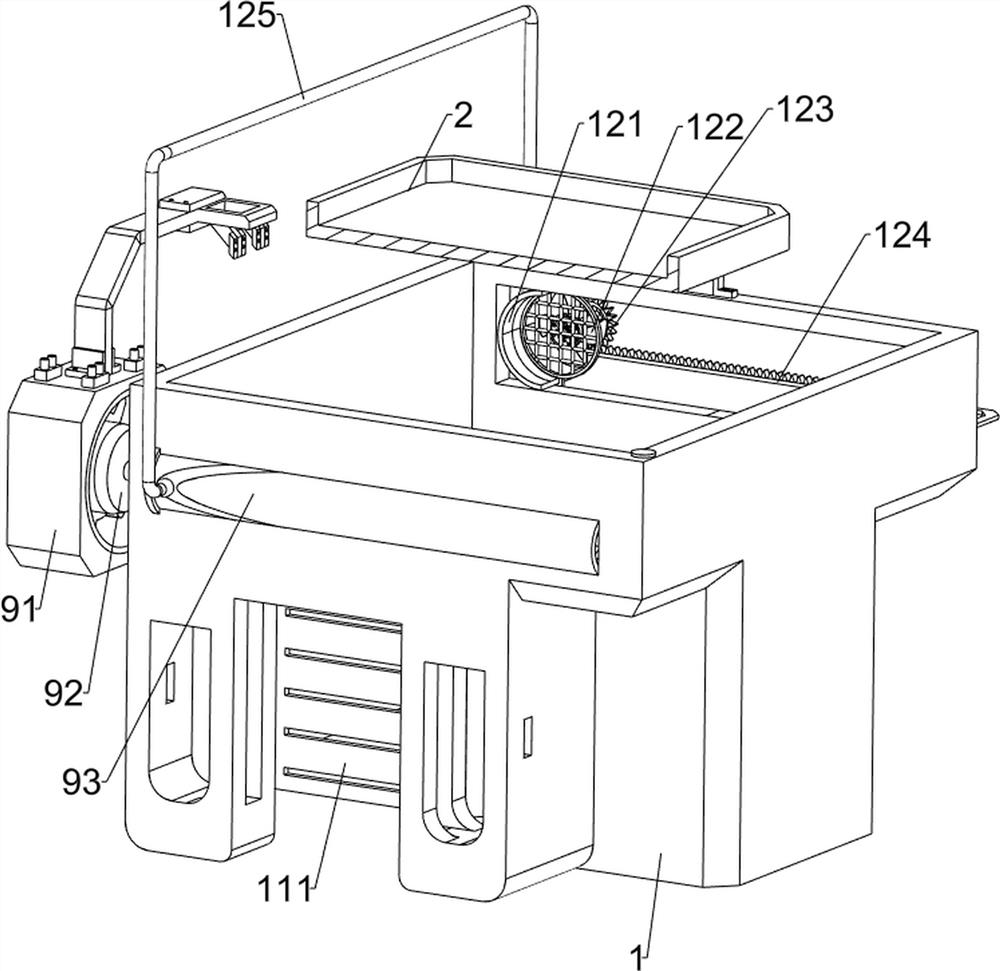

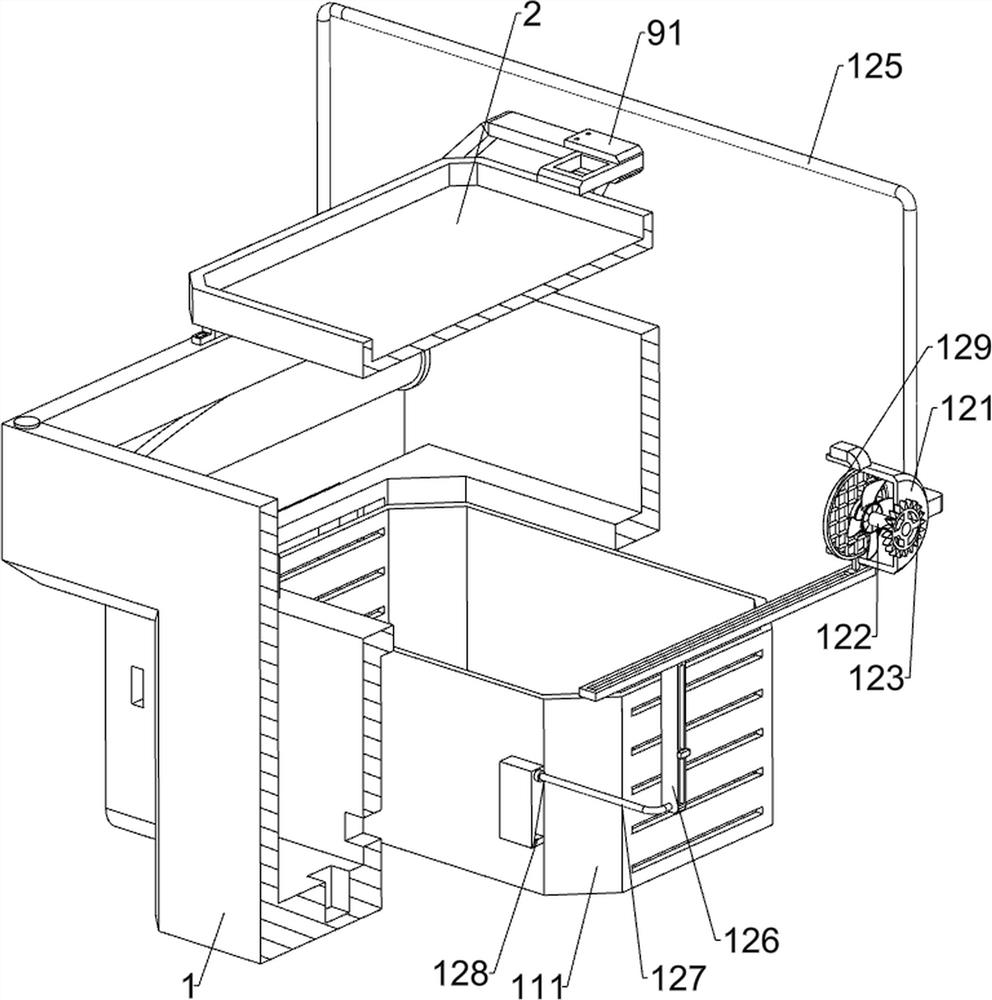

[0046] On the basis of Example 1, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 and Figure 10 As shown, a drive assembly 9 is included. The drive assembly 9 includes a fixing frame 91, a servo motor 92, a cylinder 93, an L-shaped rod 94 and a moving rod 95. The rear side of the mounting frame 2 is fixed with a fixing frame 91 by bolts. The lower part of the frame 91 is provided with a servo motor 92, the upper left part of the worktable 1 is provided with a rotary cylinder 93, the cylinder 93 is connected with the output shaft of the servo motor 92, and an L-shaped rod 94 is welded on the rear side of the middle first clamping block 82 , the lower part of the L-shaped rod 94 is provided with a moving rod 95, and the moving rod 95 is matched with the cylinder 93.

[0047] After the leather is placed, the staff starts the servo motor 92 to rotate, drives the cylinder 93 to rotate, and then drives the moving rod 95 to push backwards, drives the L-shaped rod 94 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com