Coal-fired boiler metering and weighing device

A coal-fired boiler and measuring scale technology, which is applied in the field of weighing devices for discontinuous feeding coal-fired boilers, can solve problems such as increasing the time for adding coal, complicated procedures, and error operations, so as to save time and avoid waste , the effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

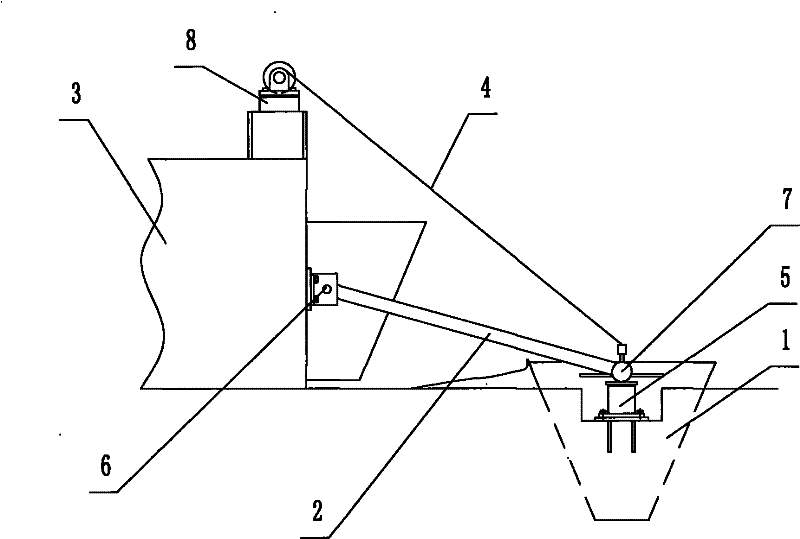

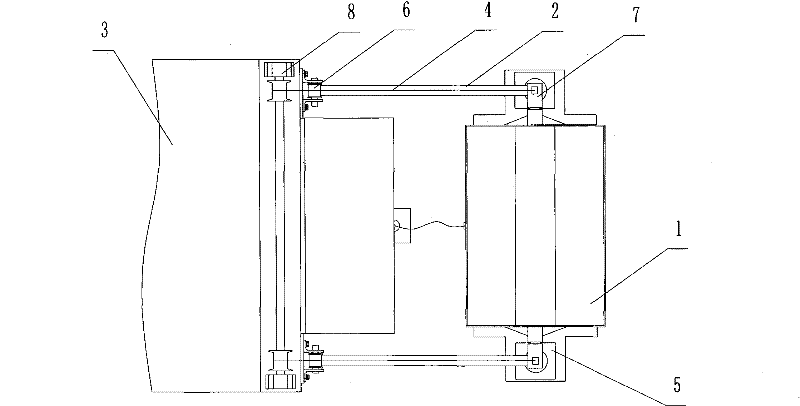

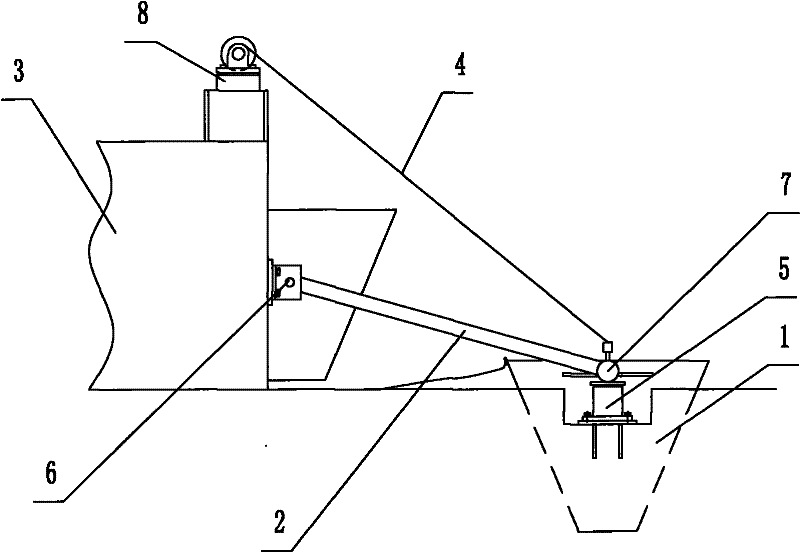

[0014] Such as figure 1 , figure 2 As shown, a charpy beam metering coal hopper for a coal-fired boiler of the present invention comprises a trapezoidal coal hopper 1 with a trapezoidal cross section, and a rotatable rocker 2 is riveted on the left and right sides of the coal hopper 1, and the other side of the rocker 2 One end is connected with the bracket 3, the rocker arm 2 can rotate around the rotary joint 6 connected with the bracket 3, the end of the rocker arm 2 close to the coal bucket 1 is connected with the steel wire rope 4, and the other end of the steel wire rope 4 goes around the top of the bracket 3 The pulley from the simply supported beam, the support 3 is provided with a bottom load cell 5 on the support rod below the side of the coal hopper 1, an S-shaped pressure sensor 8 is arranged on the simply supported beam, and the rocker arm 2 and the coal hopper 1 A shaft pin sensor 7 is arranged at the rotating shaft, and each sensor is connected with the weighi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com