Intelligent pallet having weighing function and weight recording system thereof

A statistical system and pallet technology, used in weighing indicating devices, packaging, instruments, etc., can solve the problem of inability to weigh goods on pallets, and achieve the effect of convenient weighing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

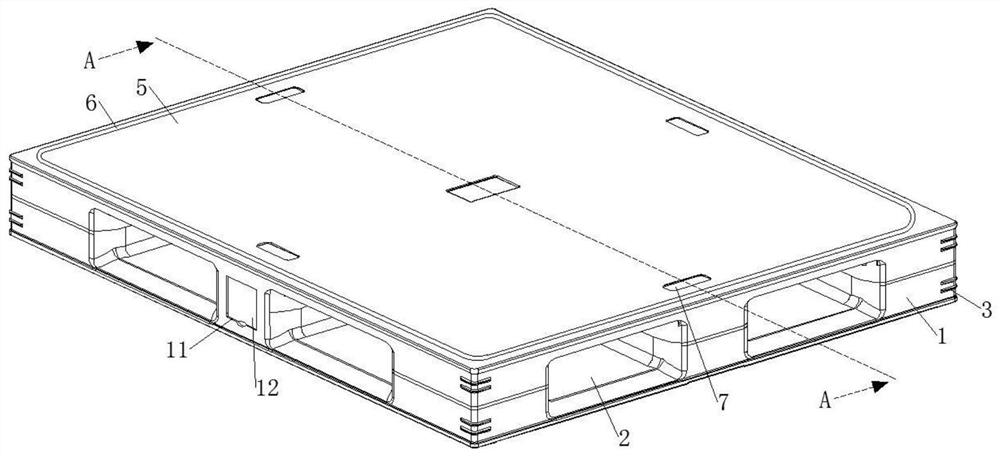

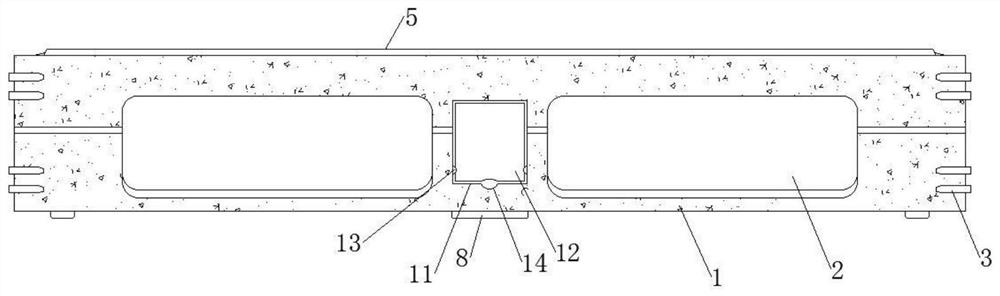

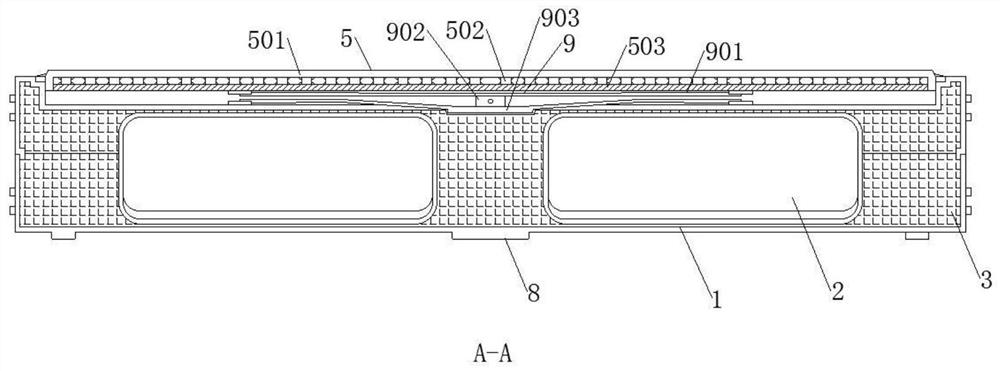

[0027] An intelligent pallet with a weighing function and its weighing statistics system, comprising a pallet main body 1, fork holes 2 are opened on the outer surface of the pallet main body 1, a load-bearing component 5 is embedded in the upper surface of the pallet main body 1, and the load-bearing component 5 includes a load-bearing plate 501, and the bottom of the load-bearing plate 501 is connected and fixed with the tray main body 1 by adhesives, the lower surface of the load-bearing plate 501 is evenly fixed with reinforcement piles 502, and the bottom of the reinforcement piles 502 is bonded and fixed with a support plate 503, improving the support strength of the load bearing plate 501, the bottom end of the support plate 503 is fixed with a weighing assembly 9, and the weighing assembly 9 includes a first balance frame 901, and the four corners of the first balance frame 901 are fixed by screws. Pile 904, the lower surface of the first balance frame 901 is fixed with...

Embodiment 2

[0037] Including the tray main body 1, the outer surface of the tray main body 1 is provided with fork holes 2, the upper surface of the tray main body 1 is embedded with a load-bearing component 5, the load-bearing component 5 includes a load-bearing plate 501, and the bottom of the load-bearing plate 501 is buckled around the bottom The main body 1 of the structural tray is connected and fixed to facilitate the disassembly of the load-bearing plate 501. The lower surface of the load-bearing plate 501 is uniformly fixed with reinforcing piles 502, and the bottom of the reinforcing piles 502 is bonded and fixed with a support plate 503 to improve the supporting strength of the load-bearing plate 501. The bottom end of the support plate 503 is fixed with a weighing assembly 9, and the weighing assembly 9 includes a first balance frame 901. The four corners of the first balance frame 901 are fixed with fixed piles 904 by screws, and the fixed piles 904 are made of rubber. To impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com