Rigid structure comprising means for positioning a soundproofing panel, and corresponding soundproofing panel

A rigid structure and sound insulation panel technology, applied in the field of rigid structure, can solve the problems of difficult parts of the sound insulation panel, poor sound sealing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

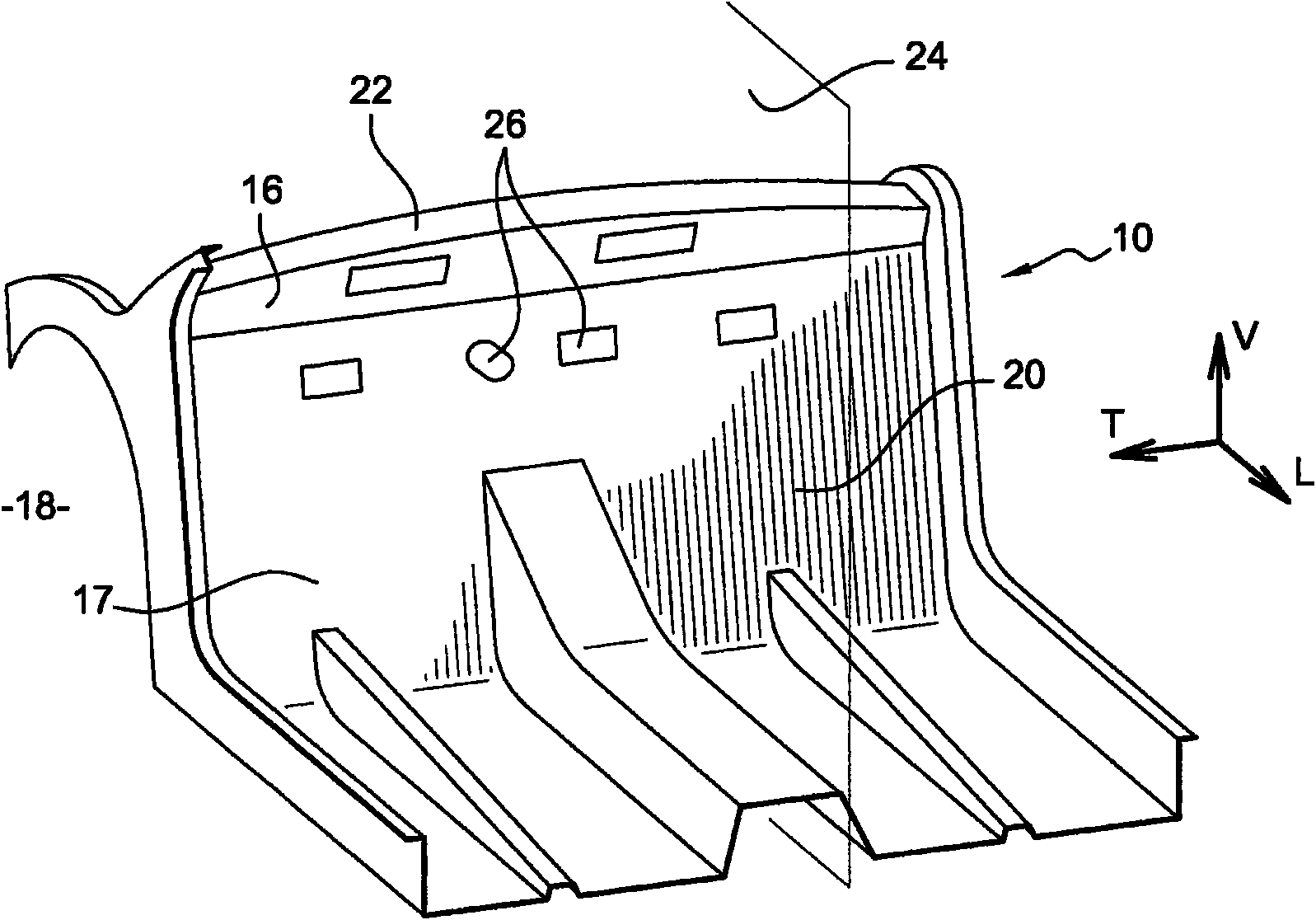

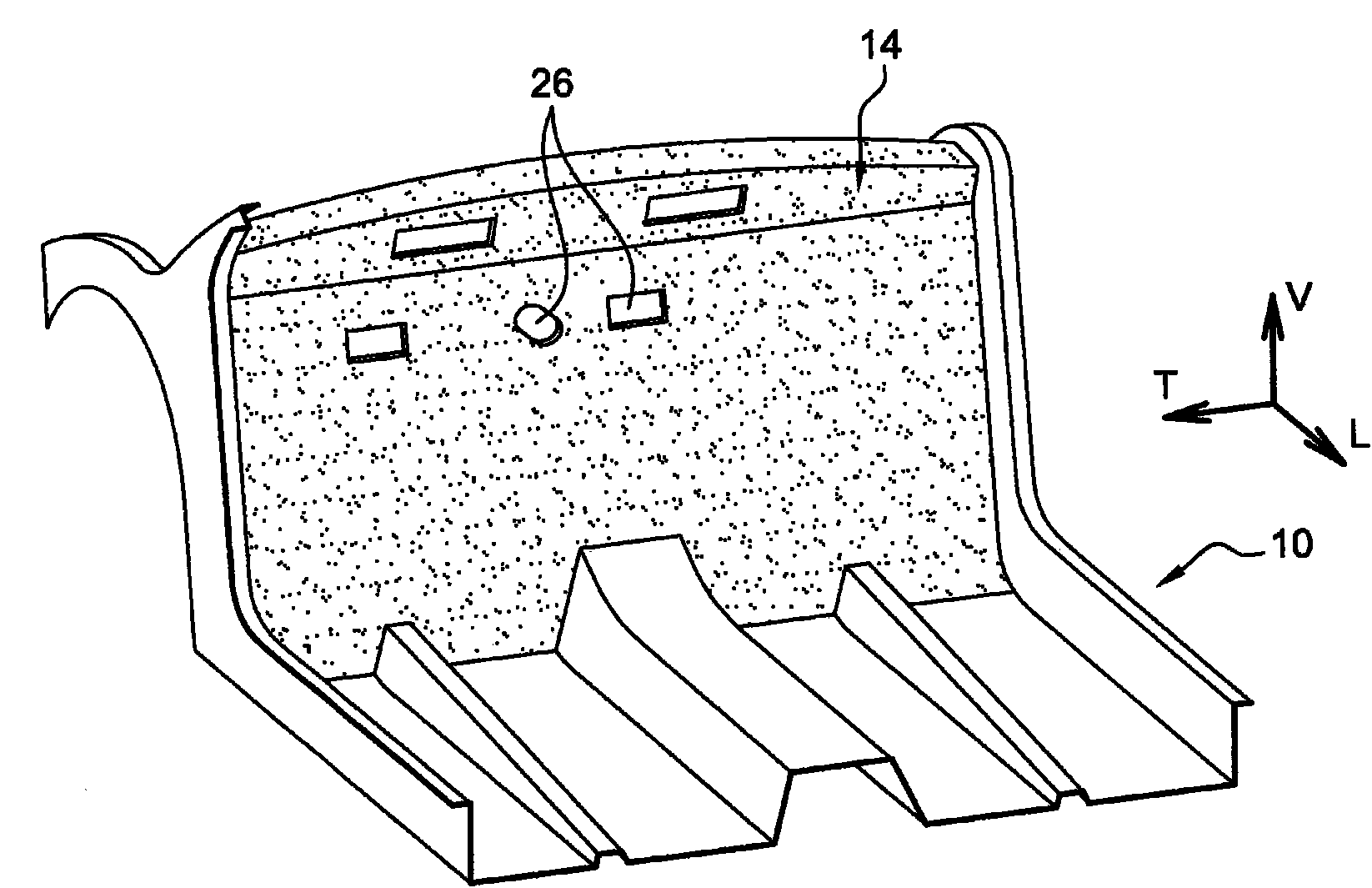

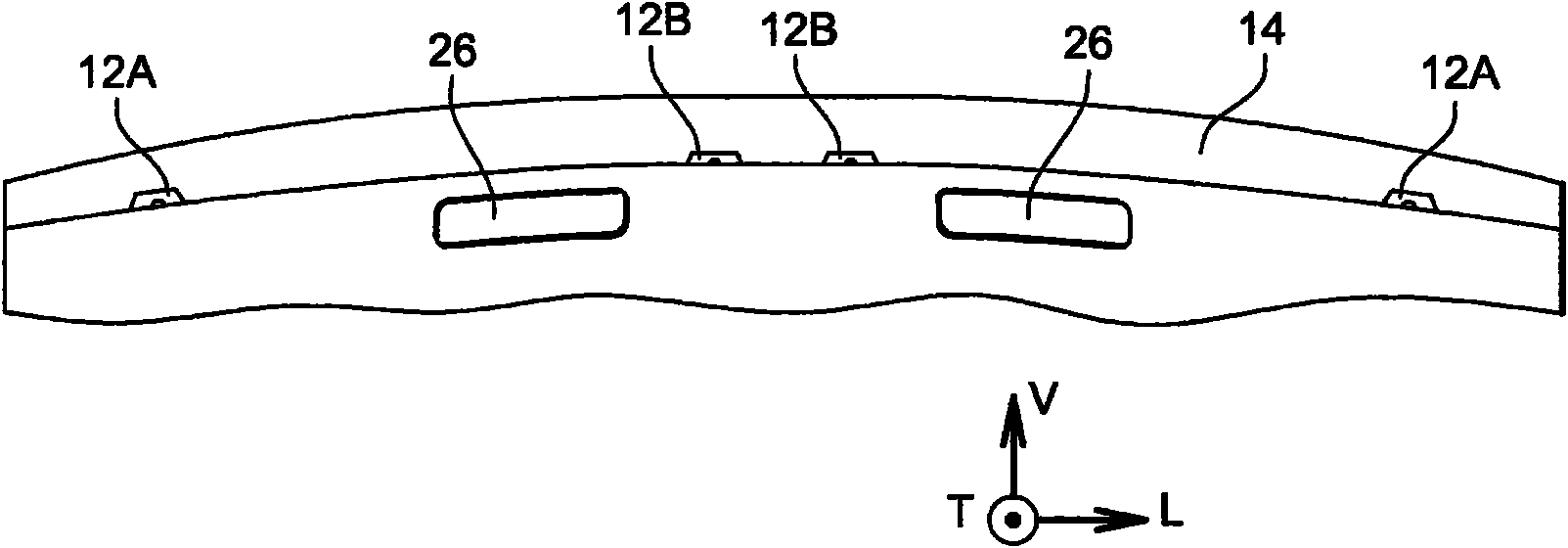

[0028] Referring to the drawings, the present invention discloses a rigid structure 10 comprising means 12 for attaching an acoustical panel 14 to the rigid structure prior to fastening the acoustical panel 14, for example with staples. positioned on this rigid structure.

[0029] According to our embodiment, the rigid structure 10 of the invention is a motor vehicle body structure for separating the engine compartment 18 from the passenger compartment 20 . A number of cables or pipes run through the structure, for example to power the various electrical or electronic components of the instrument panel or to condition the air in the passenger compartment.

[0030] The structure generally comprises in its upper part a beam 22 extending transversely, as its name implies, and a heated baffle 16 placed below the beam in a position encompassing the transverse direction and in the vertical plane. A front partition wall 17 is also placed below the baffle plate 16, and the front par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com