Tea making machine

A technology for making tea machines and tea cups, which is applied in beverage preparation devices, household utensils, applications, etc. It can solve the problems of odor accumulation and repeated brewing, so as to save tea and meet the needs of different tea drinkers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

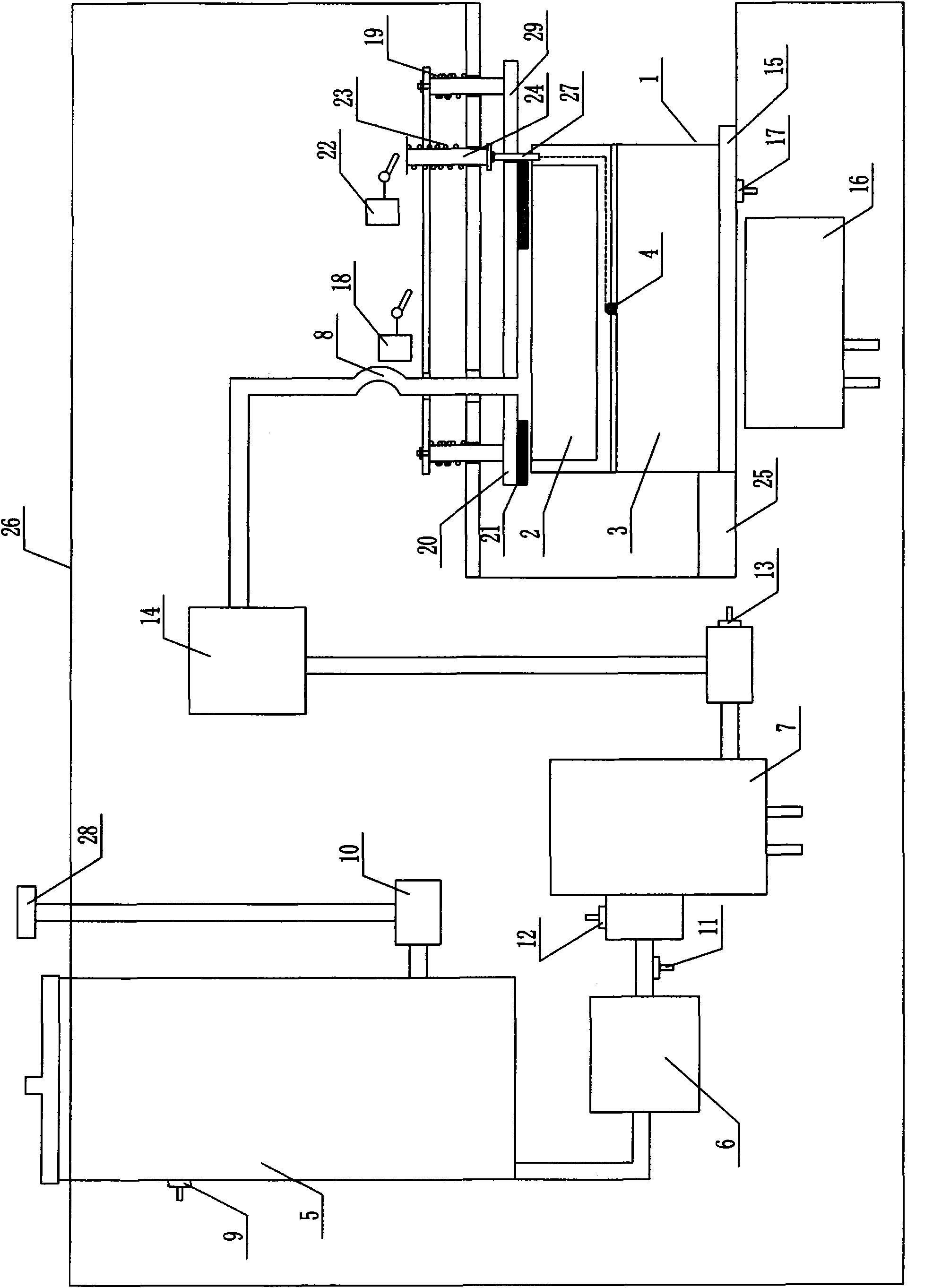

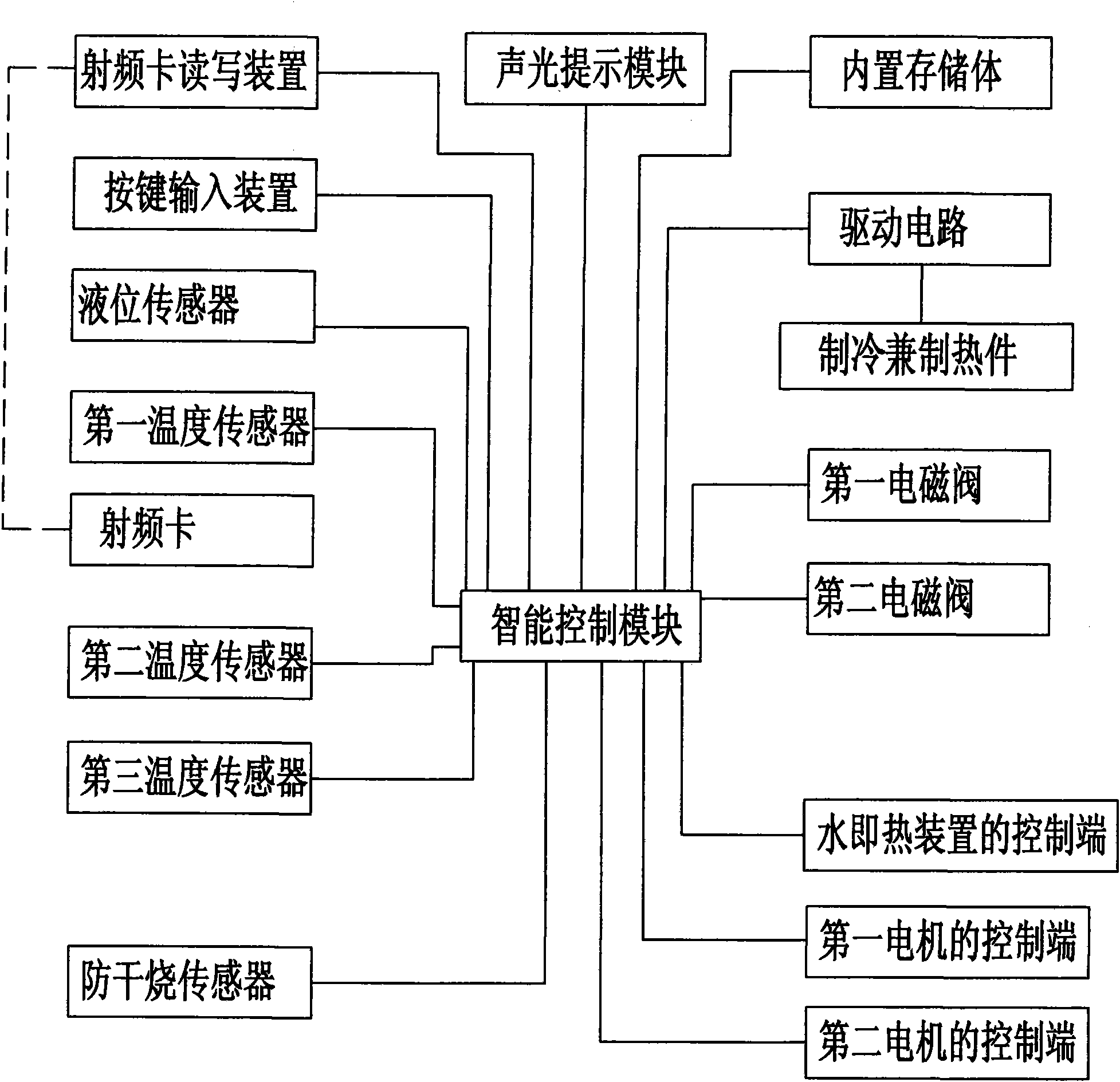

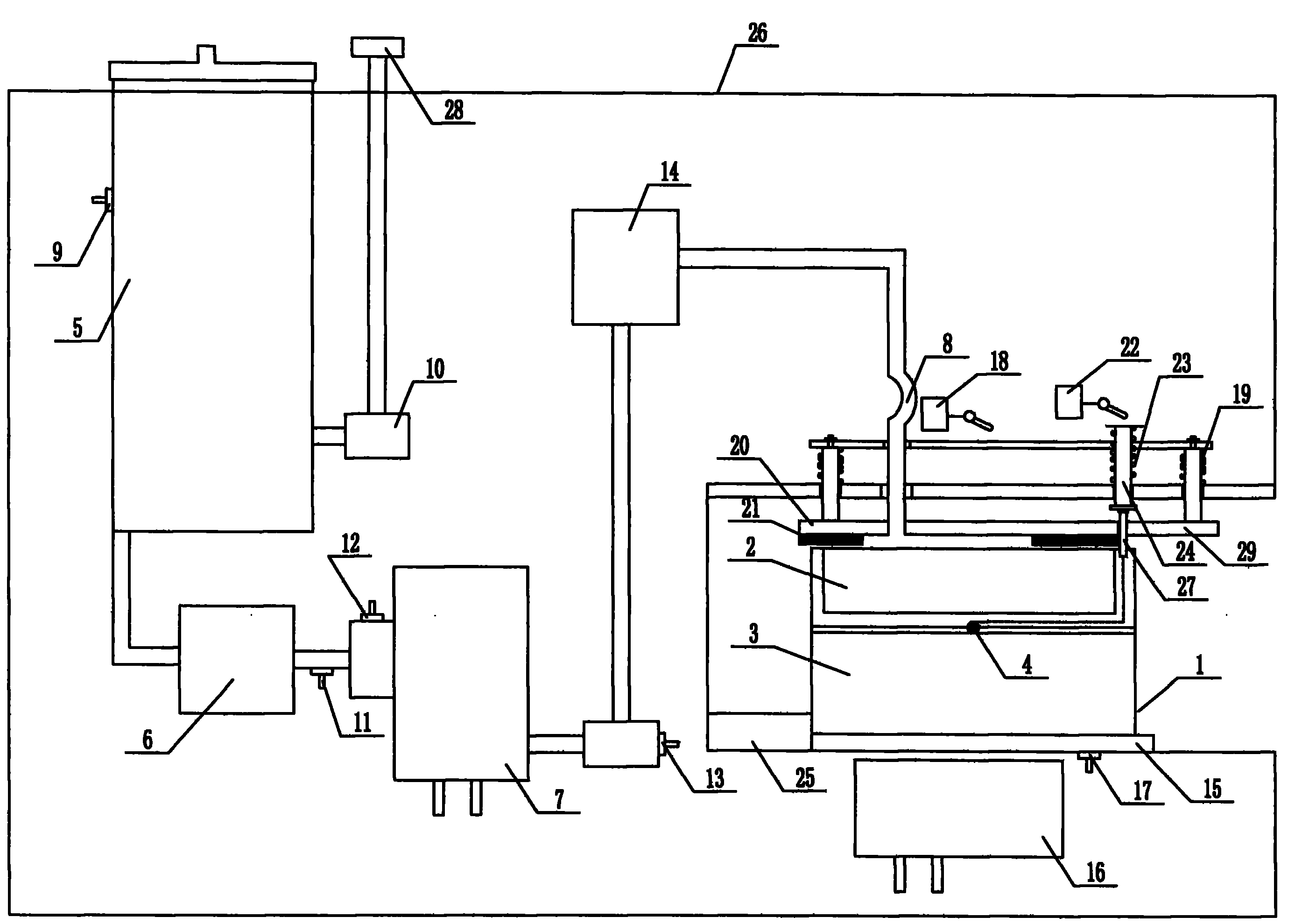

[0015] Attached below figure 1 , 2 The present invention is further described.

[0016] The tea making machine of the present invention includes a water supply unit, a tea making unit and a control unit, the control unit includes an intelligent control module, an input and output module, a storage module and an acousto-optic prompt module, and the input and output module, the storage module and the acousto-optic prompt module The prompt module is electrically connected with the intelligent control module respectively. The tea making unit is composed of a plurality of tea making cups 1 with the same structure. The tea making cup 1 is provided with a tea making room 2 and a tea storage room 3. There is a water outlet, a valve 4 is provided between the tea making room 2 and the tea storage room 3 to control whether the tea making room 2 and the tea storage room 3 are connected, and the tea making room 2 communicates with the water outlet of the water supply unit.

[0017] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com