Support member used for clutch apparatus having two friction clutches

A technology for friction clutches and clutch devices, which is applied in the direction of friction clutches, clutches, fluid-driven clutches, etc., which can solve the problems of difficult control of clutch devices and adverse effects on driving comfort, and achieve the effect of improving driving comfort and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

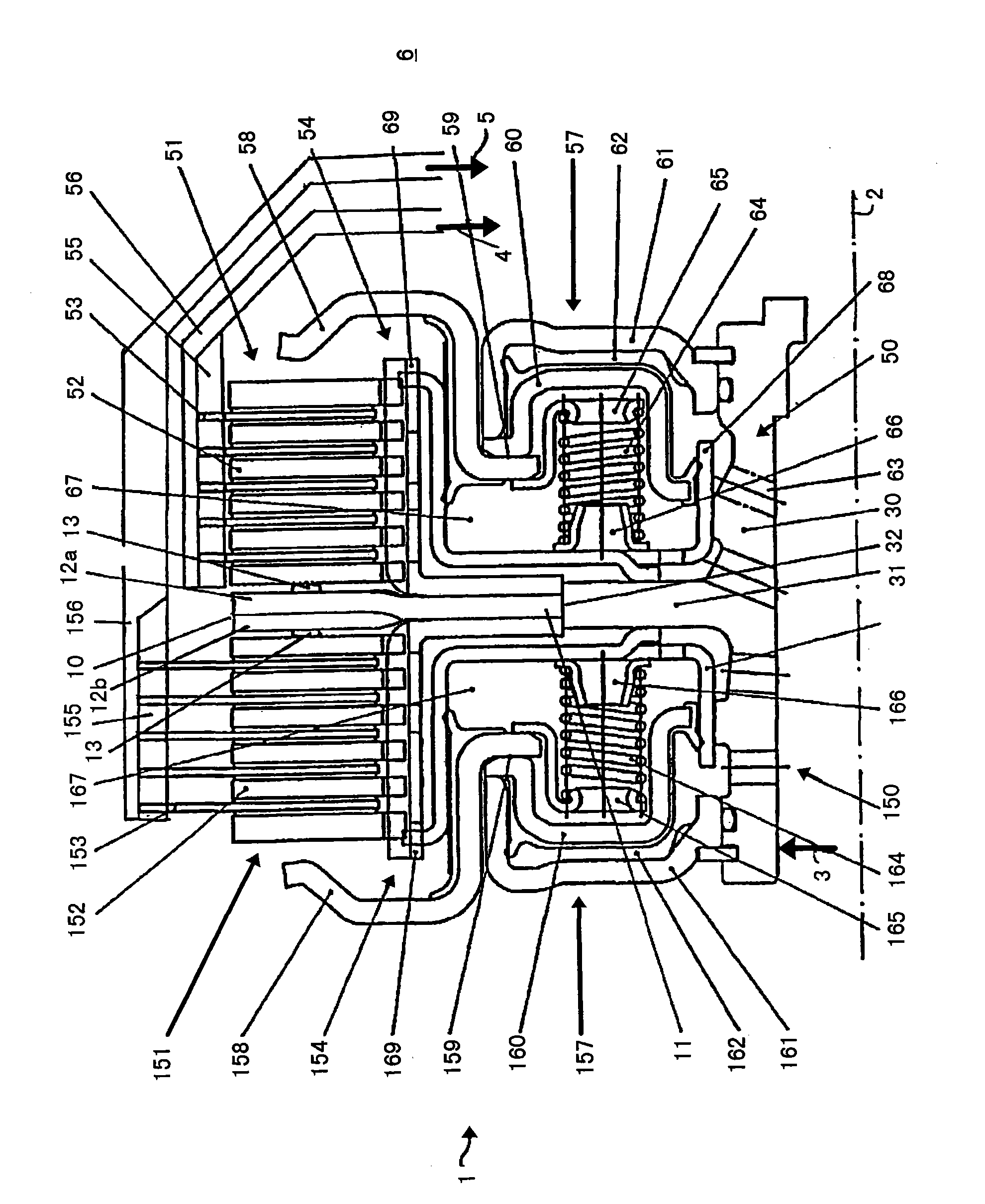

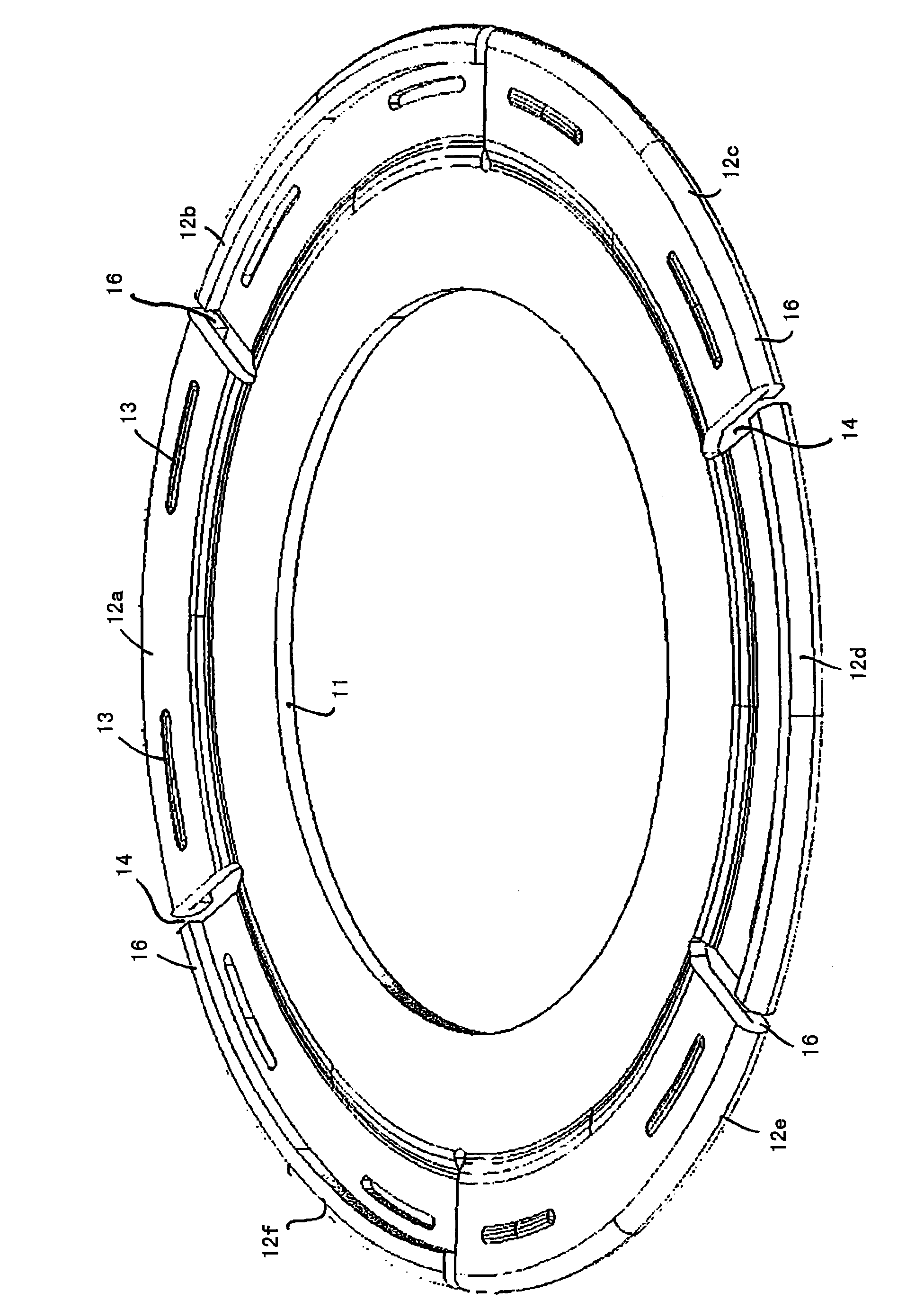

[0028] figure 1 Shown is part of a clutch device 1 in which a support element 10 according to the invention is used. The clutch device 1 can be mounted, for example, in a motor vehicle between the motor vehicle's engine and a transmission with two transmission input shafts. The clutch device 1 has a first friction clutch 50 and a second friction clutch 150 which are arranged side by side in the direction of the main clutch axis 2 , ie axially side by side. The first friction clutch 50 and the second friction clutch 150 are substantially constructed identically, so only the first friction clutch 50 will be discussed in detail below.

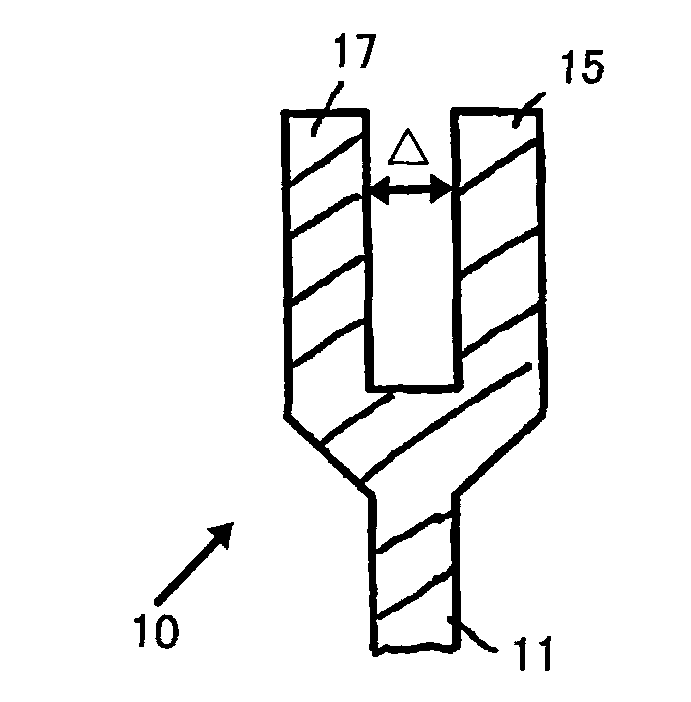

[0029] The first friction clutch 50 includes a first plate pack 51 having an inner plate 52 and an outer plate 53 . The inner disc 52 is connected to the first inner disc carrier 54 in a rotationally fixed manner, but displaceable along the main clutch axis 2 . The outer disk 53 is axially displaceable and fixedly connected to a first outer dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com