Novel anti-slippage airbrick

A hollow brick, error-proof technology, applied in the direction of earthquake resistance, building components, buildings, etc., can solve problems such as the inability of the ribs to interlock, the falling bricks to hurt people, and the wrong movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

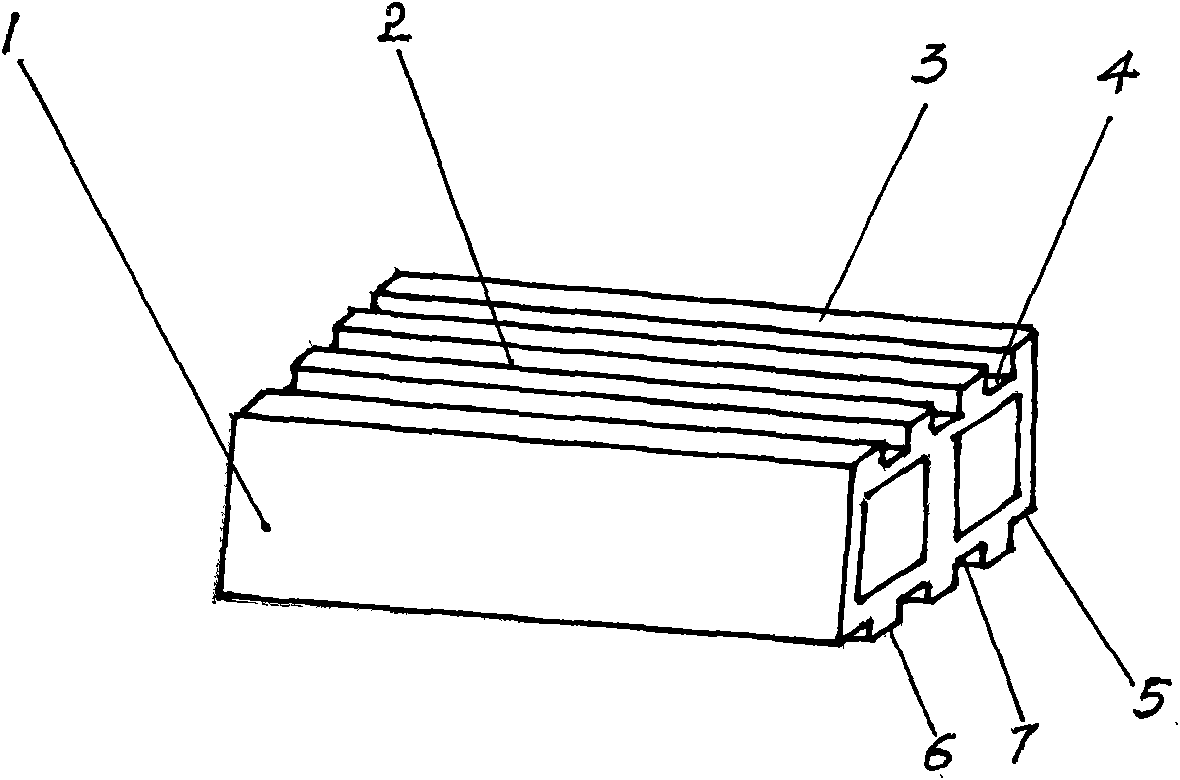

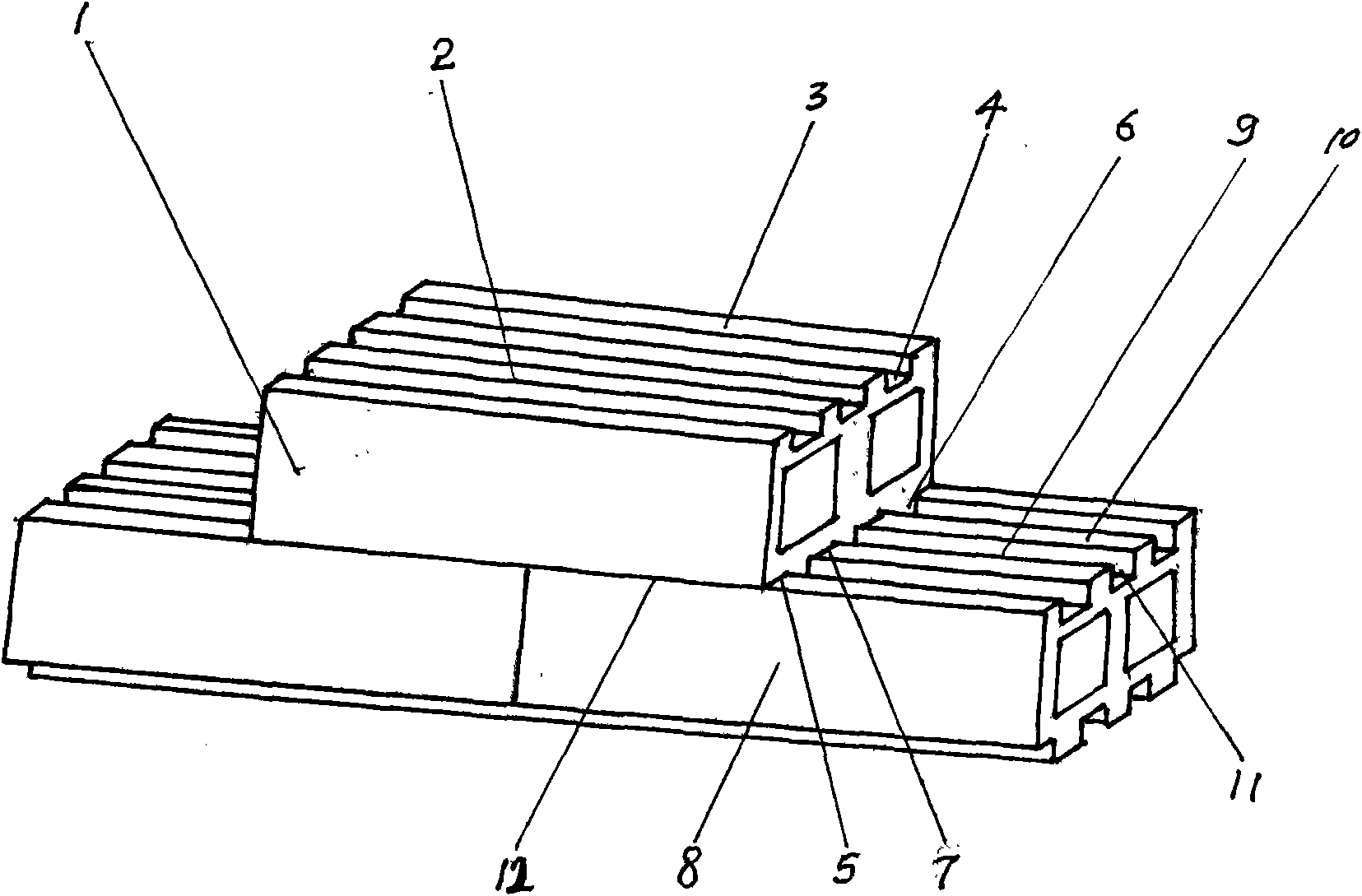

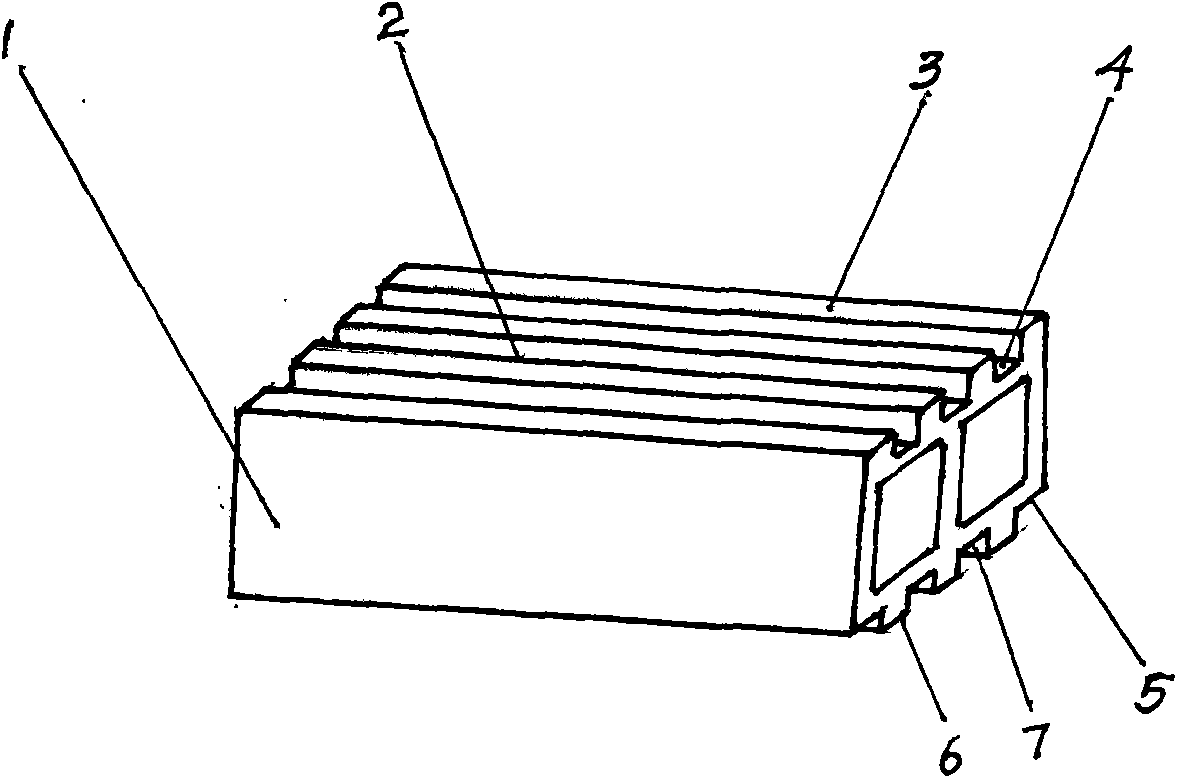

[0007] attached figure 2 It is an application example of the present invention. In this example, the present invention is a novel anti-staggering hollow brick 1 with a width of 115mm by molding and firing. On the large surface 2 of the brick 1, four straight ribs 3 are made in parallel from the outside to the inside from the two long side edges, and three straight grooves 4 are naturally formed between the straight ribs 3. The straight rib 3 has a width of 15mm and a height of 8mm. The width of the straight groove 4 is 17.5 mm. The lengths of the straight ribs 3 and the straight grooves 4 are both brick lengths, and the cross-sections are rectangular. On the large face 5 of the brick 1, 3 straight ribs 6 and 2 straight grooves 7 are made in parallel from the outside to the inside at 17.5 mm from the two long side edges. The width of straight rib 6 is 15mm. The width of the straight groove 7 is 17.5mm. The height of the straight rib 6 is 8mm, and the length of the straigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com