Steam system

一种蒸汽系统、蒸汽的技术,应用在蒸汽系统领域,达到结构以及控制简易、效率好、防止浪费的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Hereinafter, specific examples of the present invention will be described in detail based on the drawings.

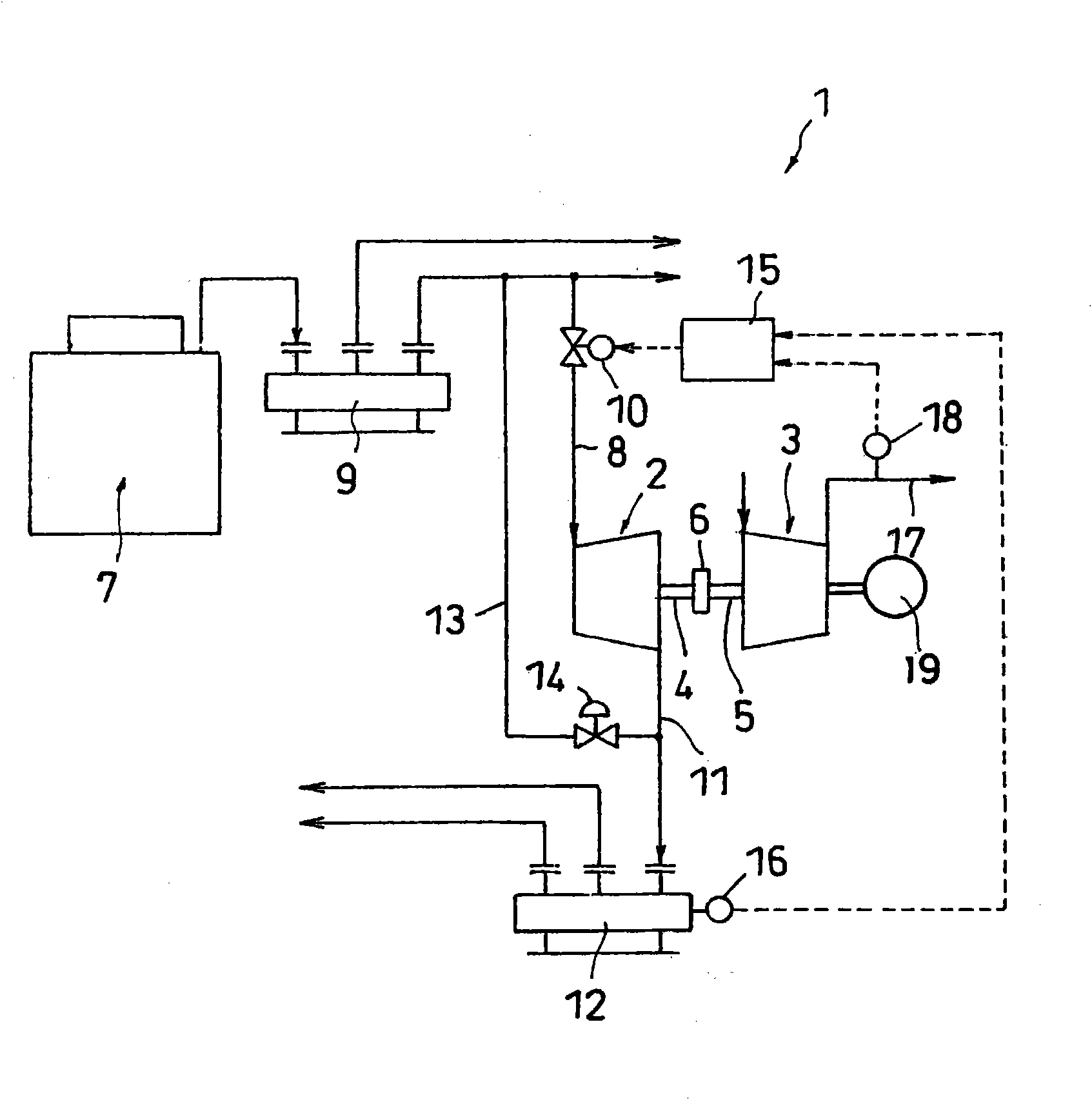

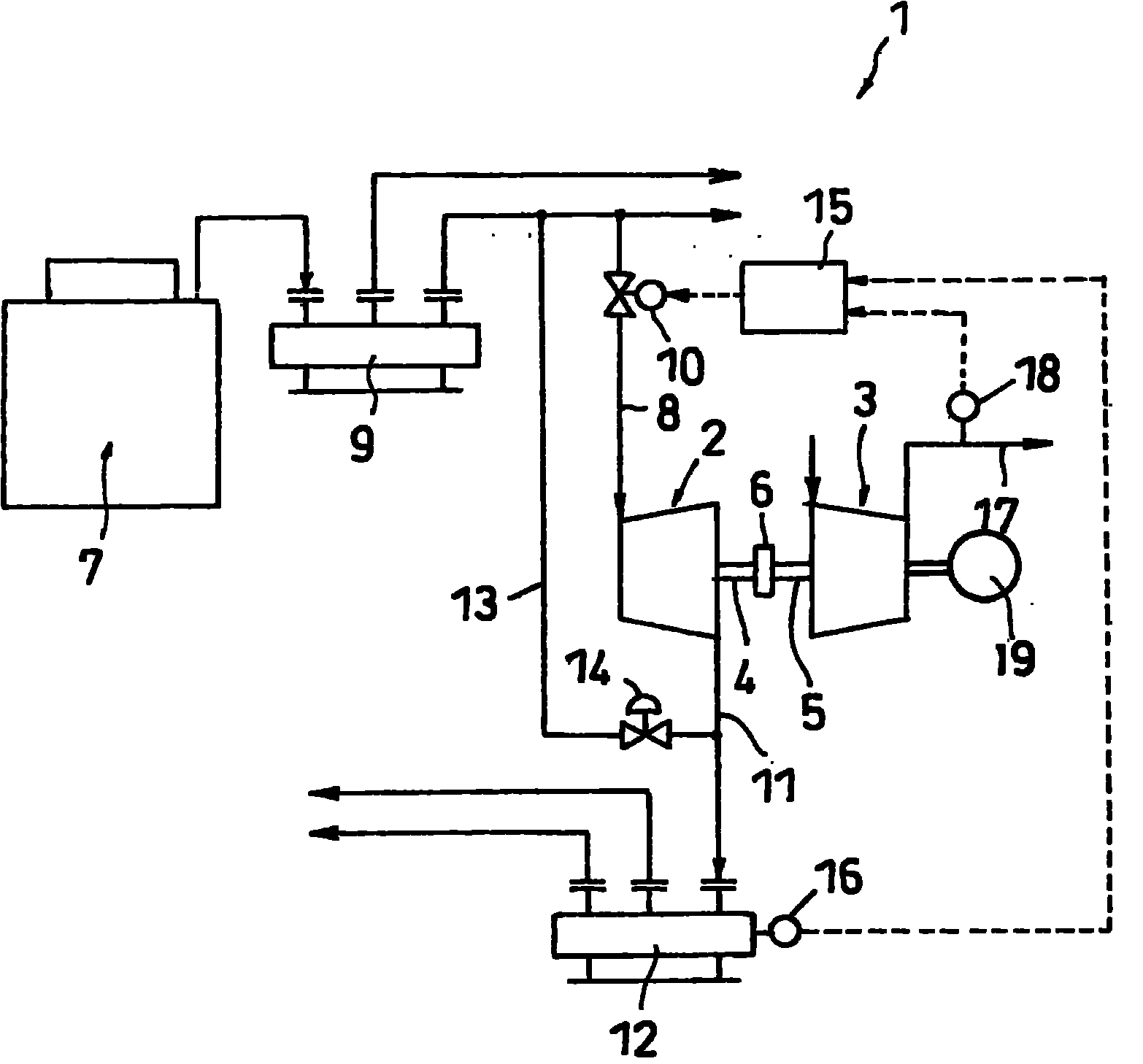

[0077] figure 1 It is a schematic diagram showing Example 1 of the steam system of the present invention. The steam system 1 of this embodiment has a prime mover 2 that generates power using steam, and a driven machine 3 driven by the prime mover 2 .

[0078] The prime mover 2 is a steam system that receives steam to generate power. The steam engine 2 may be a steam turbine, but is suitably a screw steam engine. A screw steam engine is a device that introduces steam between meshing screw rotors, uses the steam to rotate the screw rotors, expands and depressurizes the steam, and obtains power from the rotation of the screw rotors at this time.

[0079] The driven machine 3 is driven by the steam engine 2 and ejects or sucks fluid. Specifically, the driven machine 3 is a pump, a blower, a compressor, or a vacuum pump. The driven machine 3 of this embodiment is...

Embodiment 2

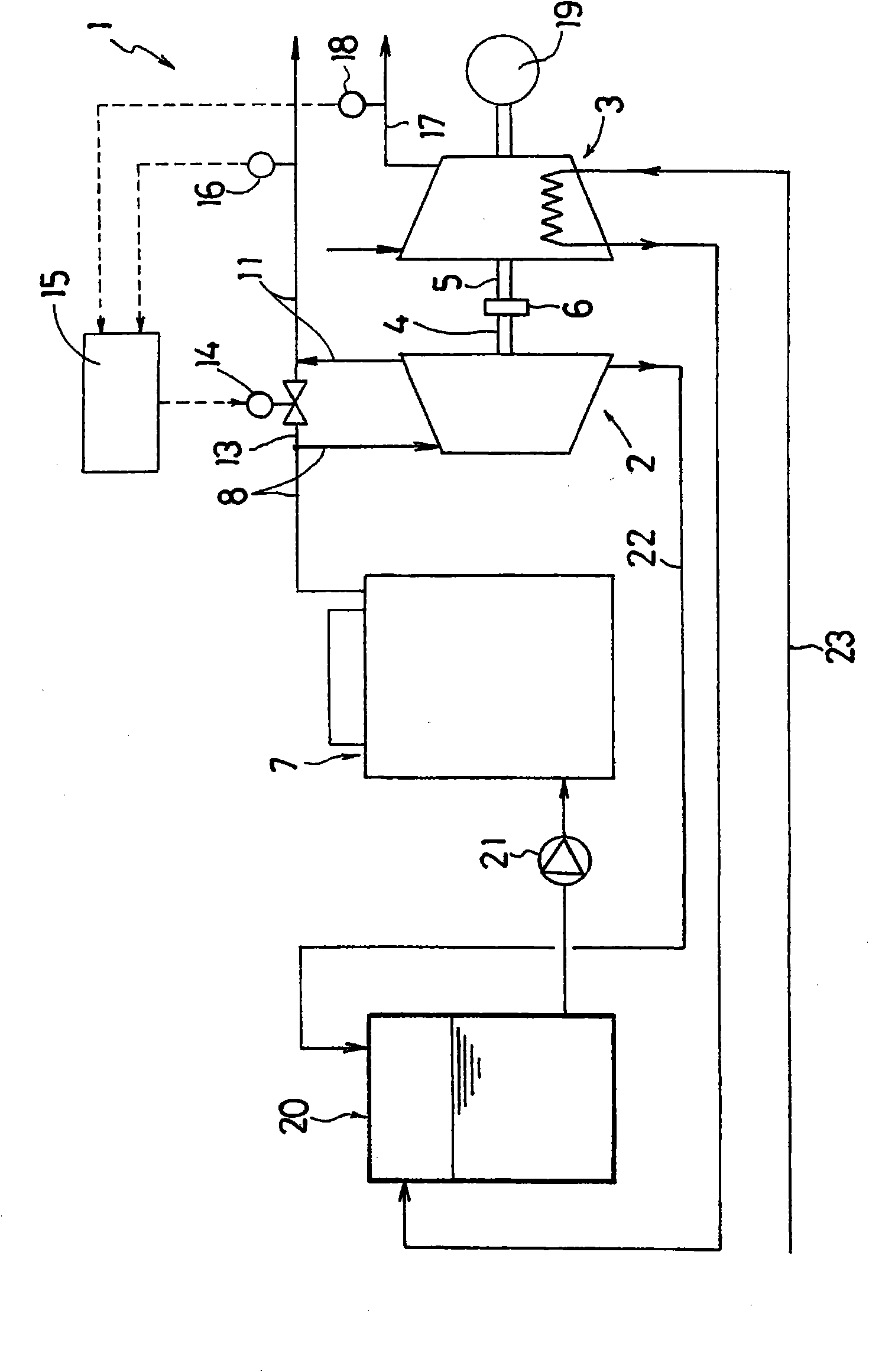

[0096] figure 2 It is a schematic diagram showing Example 2 of the steam system 1 of the present invention. The steam system 1 of the second embodiment is basically the same as that of the first embodiment. Therefore, in the following description, the differences between the two will be mainly described, and the corresponding parts will be described with the same reference numerals.

[0097] The steam system 1 of the second embodiment also has a steam system 2 that generates power using steam, and a compressor 3 driven by the steam system 2 .

[0098] The steam engine 2 of this embodiment is also a screw type steam engine. Steam from the furnace 7 is supplied to the steam engine 2 through the steam supply path 8 , and the steam used by the steam engine 2 is sent to a steam utilization device (not shown) through the steam discharge path 11 . At this time, as in the first embodiment, the steam from the boiler 7 may also be supplied to the first steam header tank 9 ( figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com