Equal angle mechanism for bus hinged tent

A hinged shed and equiangular technology, which is applied to vehicle parts, passages used to connect vehicles, transportation and packaging, etc., can solve problems such as easy deformation, low support strength, troublesome installation and maintenance, etc., to improve rigidity, strengthen strength, Uniform deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

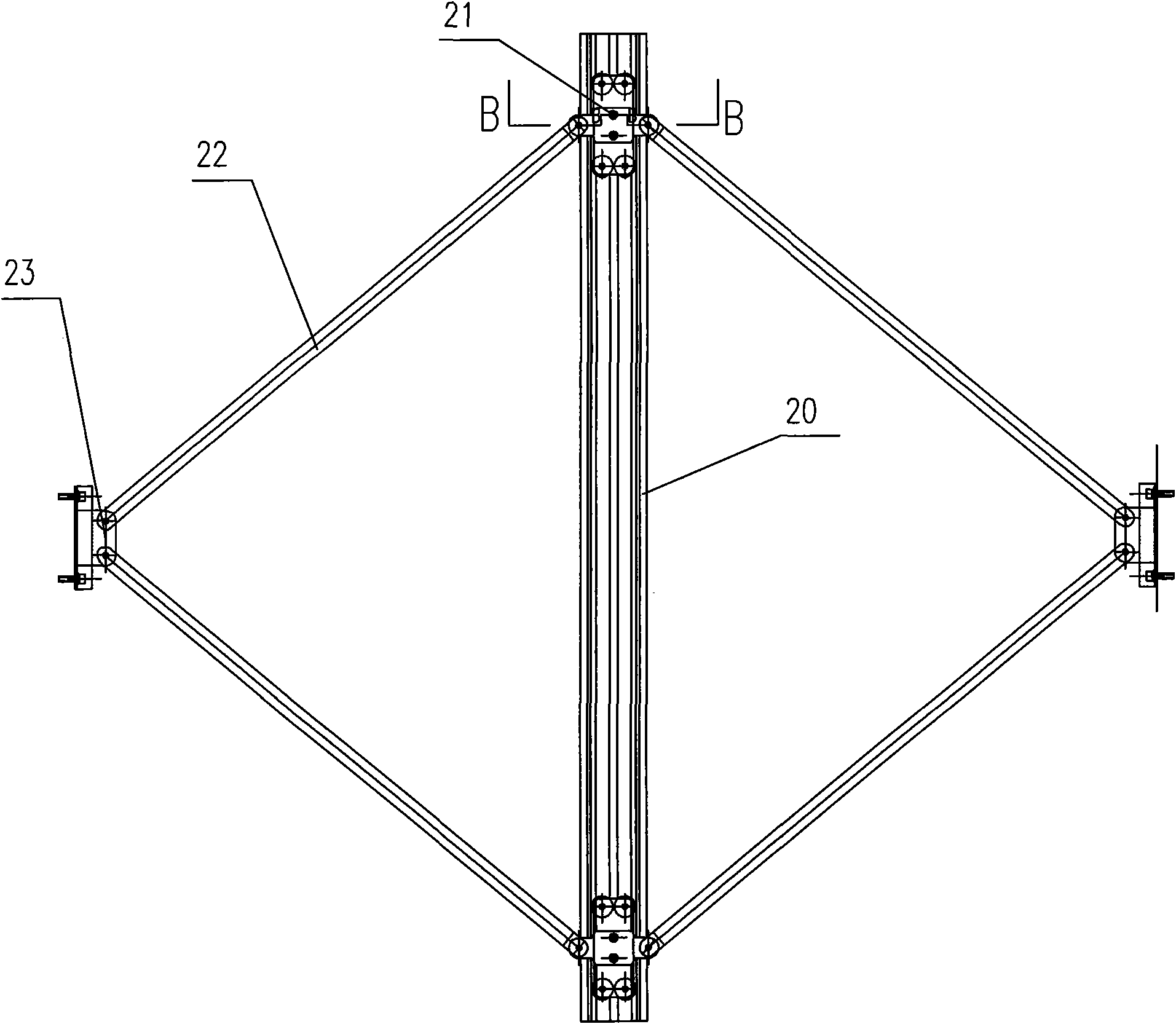

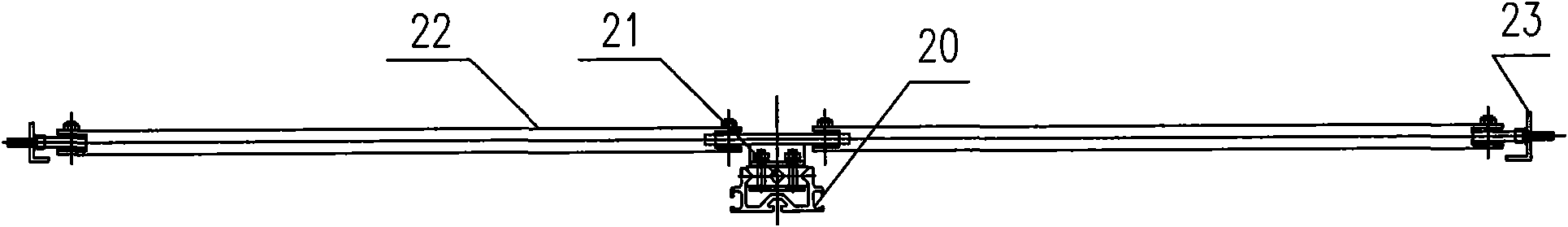

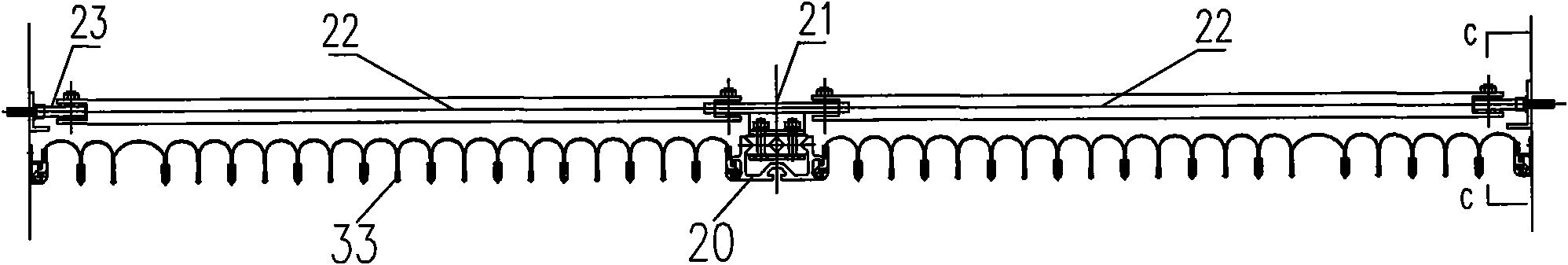

[0035] Such as figure 1 , figure 2 with Figure 4 As shown, the equiangular mechanism 2 includes a slideway beam 20, a pulley 21, a pull rod 22 and a fixed seat 23. The slideway beam 20 is a straight beam, and its two ends are connected with the two frames above the inside of the gantry frame. The left and right frame rods 112, 113 are fixedly connected, such as Figure 8 As shown, for example by angle iron and bolt fastening. Two said tackles 21 can be set movable along its linear direction on the upward slideway of said slideway beam 20, and one end of two said pull rods 22 is hinged on each said tackle 21, two on the same tackle 21 The pull rods 22 are located on both sides of the slideway beam 20 , and the other ends of the two pull rods 22 on the same side of the slideway beam 20 are hinged to one of the fixing seats 23 .

[0036] In the equiangular mechanism, a spherical connection structure is also provided between the pulley and the pull rod, and between the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com