Turbo charging system with exhaust manifold having variable necking rate

The technology of a turbocharging system and an exhaust manifold is applied in the field of the turbocharging system of an internal combustion engine and the turbocharging system, and can solve the problems of large exhaust collision loss, inability to adjust the volume of the exhaust manifold, and small volume of the exhaust manifold, etc. achieve optimal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

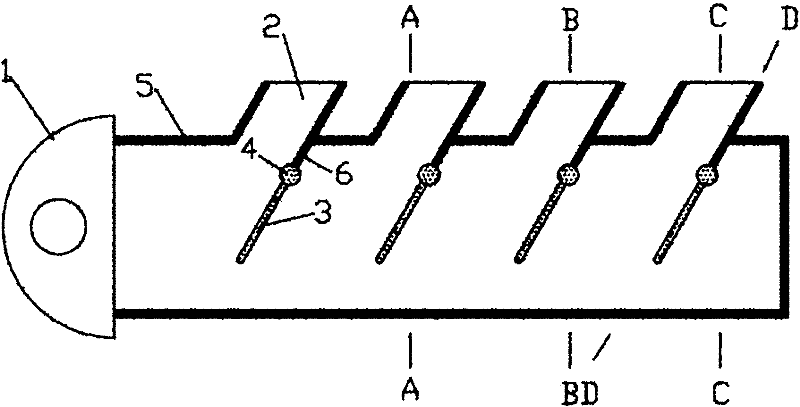

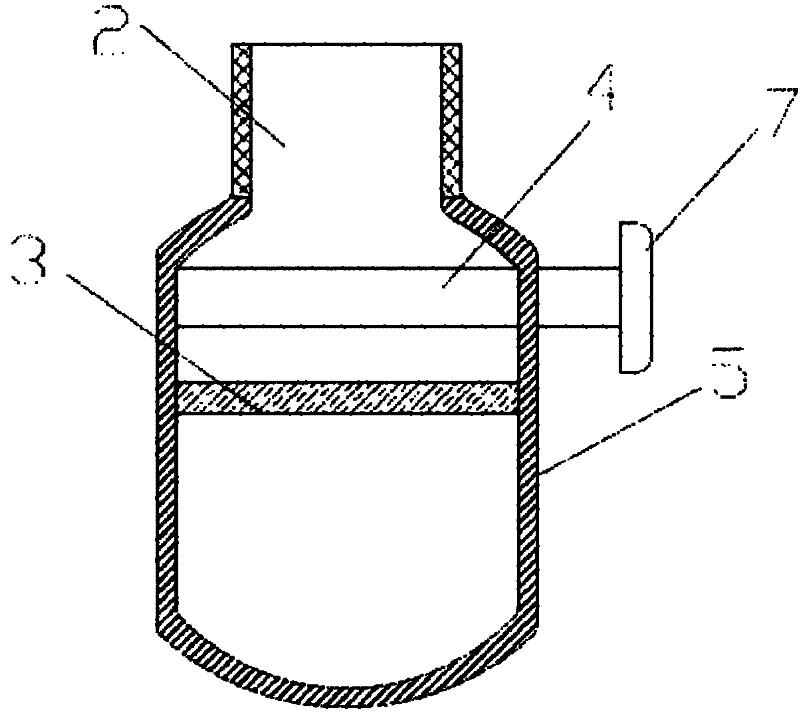

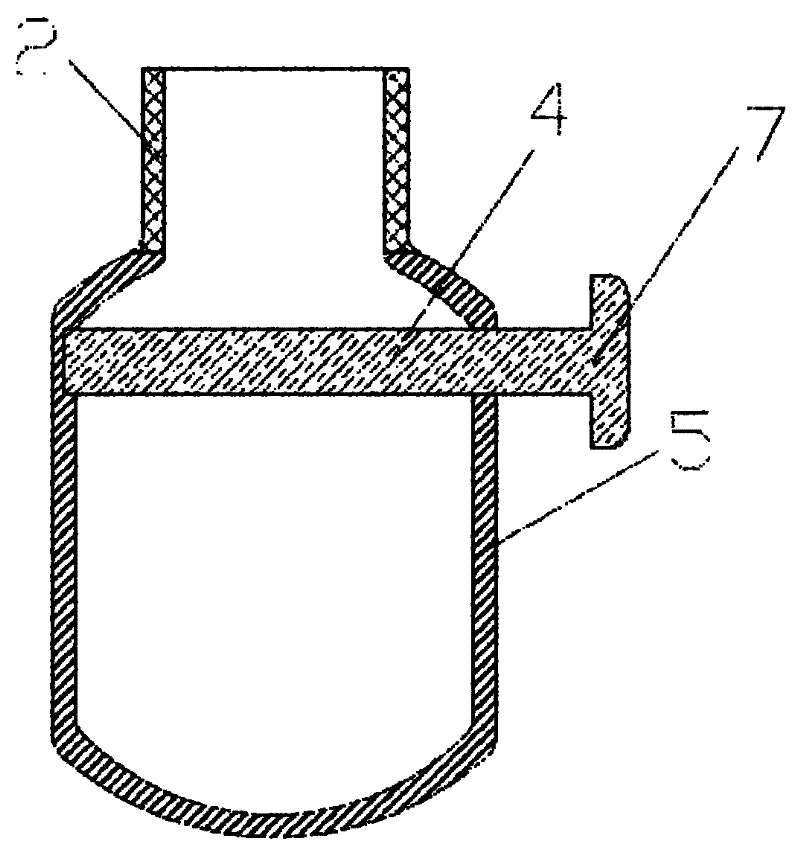

[0012] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown, the present invention comprises exhaust branch pipe 2, exhaust manifold 5, turbine 1, dividing plate 3, dividing plate shaft 4, dividing plate rotating handle 7, exhaust branch pipe deflector 6, the inlet of exhaust branch pipe 2 and cylinder The head and exhaust passages are connected, the outlet of the exhaust branch pipe 2 is connected with the exhaust manifold 5, the turbine 1 is a single-inlet turbine, the outlet of the exhaust manifold 5 is connected with the inlet of the turbine 1, and the pipe wall of the exhaust manifold 5 is formed by It is composed of two flat plates on the side and two arc plates on the upper and lower sides. One end of the partition shaft 4 is integrated with the partition rotating handle 7. The other end of the partition sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com