A Cu/Ca-based Compound Combined Cycle Capture of Co 2 method and device

A combined cycle and compound technology, which can be applied to combustion methods, fuels burned in a molten state, and fluidized bed combustion equipment, etc., can solve problems such as reducing SO emissions, and achieve the effect of simplifying the flue gas purification process and reducing emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

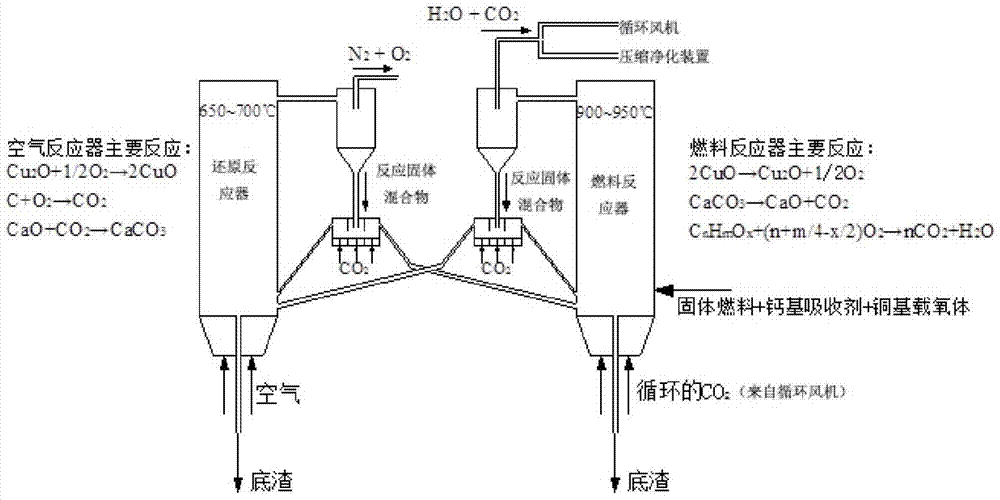

[0025] A Cu / Ca-based compound combined cycle capture of CO 2 method, such as figure 1 shown, including the following steps:

[0026] Step 1. Add the mixture of carbon-based solid fuel, calcium-based absorbent, and copper-based oxygen carrier into the fluidized bed fuel reactor, at 900-950°C, CO 2 The reaction is carried out under the condition of fluidized medium.

[0027] Carbon-based solid fuels can be carbon-based fuels such as coal, petroleum coke, and biomass, and the chemical formula is C n h m o x ; The calcium-based absorbent is CaCO 3 or CaCO 3 Natural minerals or wastes as the main component; the copper-based oxygen carrier is CuO, natural ore with CuO as the main component, or a mixture of natural ore with CuO as the main component and inert carrier; the fluidized bed fuel reactor is a cycle Fluidized bed fuel reactor or bubbling fluidized bed fuel reactor.

[0028] The following reactions mainly occur in the fluidized bed fuel reactor: CaCO 3 →CaO+CO 2 ...

Embodiment 2

[0034] CO capture using the aforementioned Cu / Ca-based compound combined cycle 2device, including a fluidized bed fuel reactor, a fluidized bed air reactor, a first cyclone separator, a second cyclone separator, a first sealed return valve, a second sealed return valve, a circulating fan, a compressor Purification device; the first sealed return valve and the second sealed return valve are sealed return valves for one-way control of return, and the connection relationship of the device is: the upper end outlet of the fluidized bed fuel reactor and the first cyclone The separator is connected, the upper outlet of the first cyclone separator is connected with the circulating fan and the compression purification device respectively, the feeding pipe of the first cyclone separator is connected with the first sealed return valve; the return section of the first sealed return valve It is connected with the dense phase area of the fluidized bed air reactor; the upper outlet of the ...

Embodiment 3

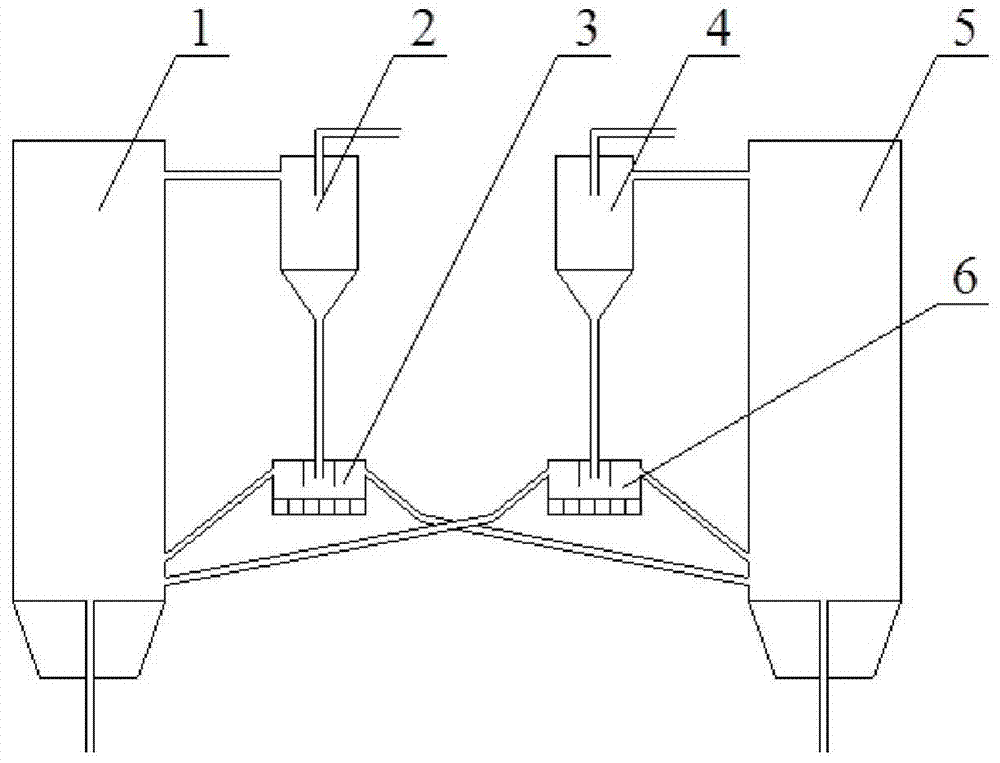

[0036] CO capture using the aforementioned Cu / Ca-based compound combined cycle 2 devices such as figure 2 As shown, it includes a fluidized bed fuel reactor 5, a fluidized bed air reactor 1, a first cyclone separator 4, a second cyclone separator 2, a first sealed return valve 6, and a second sealed return valve 3. Circulating fan, compression purification device; the first sealed return valve 6 and the second sealed return valve 3 are sealed return valves for two-way control of return, and the connection relationship of the devices is: fluidized bed fuel reactor The upper end outlet of 5 is connected with the first cyclone separator 4, the upper end outlet of the first cyclone separator 4 is connected with the circulating fan and the compression purification device respectively, the feeding pipe of the first cyclone separator 4 and the first sealing return valve 6 connected; the return sections on both sides of the first sealed return valve 6 are respectively connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com