Optical proximity sensor package

A technology of optical proximity, ambient light sensor, applied in the field of proximity sensor, can solve the problems of different quality, difficult to manufacture, increase of sensor 10, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

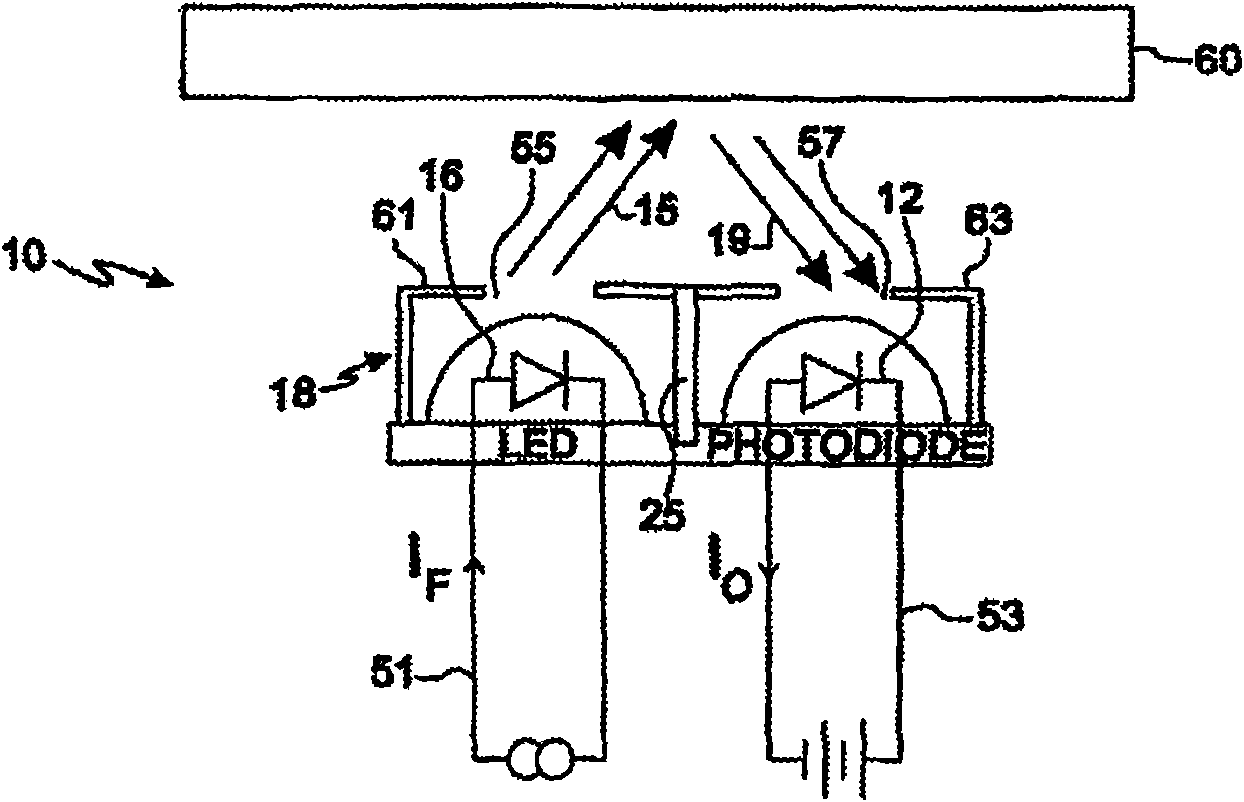

[0025] now refer to Figure 4 , shows an optical proximity sensor 10 comprising a light emitter 16 mounted on a substrate 11 and separated from a light detector 12 by an optically transmissive material 21 which is single-molded Two-part epoxy or transfer molding compound. Such as Figure 4As shown, while light ray 15 is transmitted through material 21, other reflected, diffracted or refracted IR radiation 19 may leak through single mode compound 21 to photodetector 12 and present itself as a photoemitter. Undesired crosstalk or interference between 16 and photodetector 12, thereby degrading the performance of proximity sensor 10.

[0026] Such as Figure 5 As shown, the amount of reflected, diffracted, or refracted IR radiation 19 and unwanted crosstalk or interference between light emitter 16 and light detector 12 is often exacerbated by the presence of window 23, which in some applications The device is provided as part of a portable or other type of electronic device in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com